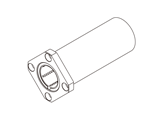

THK's LMK and LMK M SERIES flanged type Square Flange Linear Bushings represent a robust and versatile solution for linear motion applications demanding high precision, rigidity, and load capacity. As part of the renowned Ball Bushing line, these components are engineered to facilitate smooth, low-friction linear travel along a shaft, serving as a compact and highly efficient alternative to traditional slide mechanisms. The defining characteristic of this series is its square-shaped flange, which provides a large, stable mounting surface for secure and straightforward installation using standard fasteners. This design is crucial for maintaining alignment and resisting mounting surface inaccuracies, ensuring consistent performance over the bushing's operational life.

Technically, these linear bushings are distinguished by several key features. They incorporate a high-grade bearing steel construction, often with a super-hard chrome-plated finish on the rolling surfaces to enhance wear resistance and longevity. The internal structure features a precision-engineered ball retainer that ensures smooth circulation of the load-bearing balls, minimizing friction and preventing skidding even at high speeds. Many models within the series are available with seals and wipers on both sides, effectively shielding the internal ball tracks from contaminants like dust, chips, and moisture, while also retaining the grease lubrication essential for quiet operation and extended service life. The LMK M SERIES typically denotes a wider, more rigid version, offering even greater load capacity and moment resistance compared to the standard LMK model.

The performance advantages of the LMK and LMK M SERIES are substantial. Their high rigidity and large load capacity—encompassing radial, reverse radial, and moment loads—make them exceptionally stable under demanding conditions. This results in highly accurate, repeatable linear motion with minimal deflection. The low-friction operation contributes to high efficiency, requiring less driving force and enabling higher speeds, which can lead to energy savings and increased throughput in automated systems. Their compact, self-contained design simplifies machine construction, reduces the need for complex machining of guide surfaces, and allows for easier maintenance and replacement.

These attributes make the Square Flange LMK and LMK M SERIES ideal for a vast array of applications across multiple industries. In industrial machinery, they are commonly found in the linear axes of automated assembly robots, precision positioning stages for CNC equipment, sliding doors and hatches, and the feed mechanisms of packaging and printing machines. Within the automotive sector, they are utilized in precision testing and inspection jigs, robotic welding arms, and assembly line transfer systems. For high-precision equipment, such as semiconductor manufacturing apparatus, medical diagnostic devices, and optical alignment instruments, the series' accuracy, smooth motion, and reliability are indispensable for ensuring product quality and process consistency.

THK's LMK L SERIES Linear Bushing, specifically the flanged type Square Flange Model LMK, represents a high-performance linear motion solution engineered for demanding industrial applications. This compact, precision component features a square flange design that simplifies mounting and enhances structural rigidity, making it ideal for installations where space constraints and stability are critical. The LMK L SERIES incorporates THK's proprietary Guide Ball Bushing technology, which utilizes a unique ball circulation system to ensure smooth, low-friction linear motion with minimal resistance and high positional accuracy. Key technical features include a hardened steel construction for exceptional durability, precision-ground raceways that optimize load distribution, and high-grade seals that effectively exclude contaminants like dust and debris while retaining lubrication. These design elements contribute to extended service life and consistent performance even in harsh operating environments.

Performance advantages of the LMK L SERIES are substantial, offering high load capacity in all directions—radial, reverse radial, and lateral—due to its optimized contact angle and ball groove geometry. This allows the bushing to handle complex load conditions without compromising smoothness or precision. The low coefficient of friction reduces energy consumption and heat generation, enabling higher operational speeds and accelerations while maintaining quiet, vibration-free motion. Its high rigidity minimizes deflection under load, ensuring repeatable positioning accuracy critical for automated processes. Additionally, the flanged square design provides secure, straightforward mounting, reducing installation time and improving overall system stability by distributing forces evenly across the mounting surface. Maintenance requirements are minimal, thanks to effective sealing and long-lasting lubrication, which help prevent premature wear and reduce downtime.

Typical applications for the THK LMK L SERIES Linear Bushing span various high-precision industries. In industrial machinery, it is commonly used in CNC machining centers for tool changers and spindle drives, where rapid, accurate linear movement is essential for productivity and part quality. Within automotive systems, these bushings are integral to robotic welding arms, assembly line conveyors, and testing equipment, providing reliable motion control that withstands continuous operation and variable loads. In precision equipment, such as semiconductor manufacturing devices, medical imaging systems, and optical positioning stages, the LMK L SERIES ensures sub-micron accuracy and smooth motion, critical for delicate processes and high-resolution outcomes. Its robust design also makes it suitable for packaging machinery, material handling systems, and automation robotics, where durability and low maintenance are paramount for operational efficiency. By delivering a combination of precision, reliability, and ease of integration, the THK LMK L SERIES flanged Linear Bushing supports advancements in automation and technology across diverse sectors.

THK's LMK SERIES flanged-type Square Flange Model LMK Linear Bushings represent a significant advancement in linear motion technology, engineered to deliver exceptional precision, durability, and load-bearing capacity in demanding industrial environments. These compact, high-performance components are designed with a square flange configuration that simplifies mounting and enhances structural rigidity, making them ideal for applications where space constraints and alignment accuracy are critical. The LMK SERIES incorporates THK's proprietary Guide Ball Bushing technology, which features a unique ball circulation system that minimizes friction and ensures smooth, consistent motion even under high loads and rapid cycling conditions.

Key technical features of the LMK Linear Bushings include their optimized contact angle design, which distributes loads evenly across the ball grooves to maximize rigidity and minimize deformation under stress. The flanged construction provides secure attachment points, reducing the need for additional mounting hardware and streamlining integration into machine designs. Manufactured from high-grade chromium steel and subjected to THK's rigorous heat treatment processes, these bushings offer superior wear resistance and extended service life. The inclusion of seals and wipers effectively prevents contamination from dust, chips, and other particulates, maintaining lubrication integrity and operational reliability in harsh environments.

Performance advantages of the LMK SERIES are evident in their ability to support high moment loads while maintaining precise linear guidance with minimal maintenance requirements. The low coefficient of friction inherent in the Guide Ball Bushing design translates to reduced energy consumption and heat generation, contributing to overall system efficiency. Their compact dimensions allow for space-saving installations without compromising on load capacity or accuracy, making them particularly suitable for modern machinery designs that prioritize footprint reduction.

Typical applications for the LMK flanged-type Linear Bushings span across multiple industries, including industrial automation where they are deployed in CNC machining centers, robotic positioning systems, and material handling equipment. In automotive manufacturing, these components are integral to assembly line robots, precision welding fixtures, and testing apparatus that demand repeatable accuracy under continuous operation. The precision equipment sector utilizes LMK bushings in semiconductor fabrication tools, optical alignment systems, and medical device manufacturing where sub-micron level precision is non-negotiable. Their robust construction and contamination resistance also make them well-suited for food processing machinery, packaging systems, and other applications requiring frequent washdowns or exposure to corrosive agents.