In the world of industrial machinery, automotive systems, and precision equipment, bearing performance is critical to ensuring smooth operation, reducing downtime, and extending service life. KOYO, a globally recognized leader in bearing technology, offers **self-aligning ball bearings** designed to meet these challenges with exceptional reliability and adaptability. Engineered for applications where misalignment, high speeds, and varying loads are common, KOYO’s self-aligning ball bearings provide a robust solution that enhances efficiency and reduces maintenance costs.

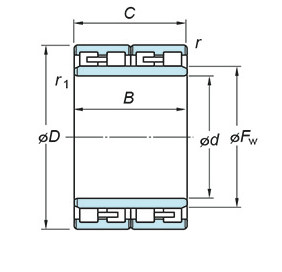

In heavy industrial environments where extreme loads, high speeds, and harsh operating conditions are the norm, KOYO’s rolling mill roll neck bearings stand as a benchmark for reliability and performance. Designed specifically for the rigorous demands of metal processing—including hot and cold rolling mills—these specialized bearings ensure smooth operation, extended service life, and minimal downtime in critical applications.

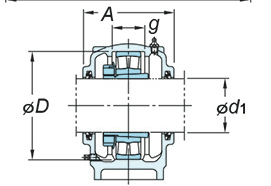

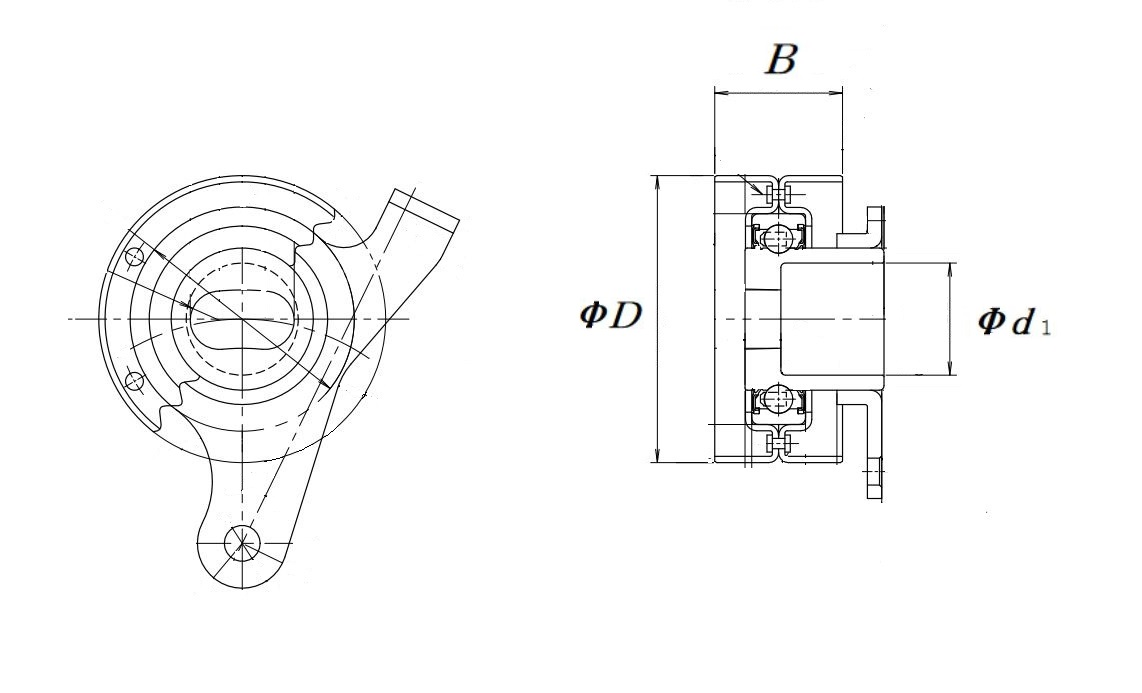

In demanding industrial environments, reliable bearing support is critical to minimizing downtime and maximizing operational efficiency. KOYO plummer blocks (also known as bearing housings or pillow blocks) deliver robust, precision-engineered solutions designed to support rotating shafts in a wide range of applications. Combining high-quality materials, advanced sealing technology, and superior load-bearing capacity, KOYO plummer blocks ensure long service life even under harsh conditions, including heavy loads, high speeds, and exposure to contaminants.

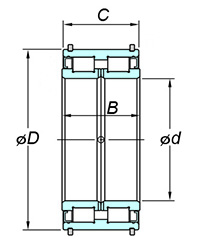

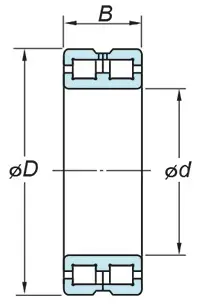

In demanding industrial environments where heavy loads, high radial forces, and continuous operation are critical, **KOYO Full Complement Type Cylindrical Roller Bearings** stand out as a robust and reliable solution—particularly for **crane sheaves and other heavy-load applications**. Engineered for maximum load capacity and durability, these bearings eliminate the need for a cage, allowing for a higher number of rollers and optimized load distribution. This design makes them ideal for applications where space constraints, shock loads, and slow-to-moderate rotational speeds are key considerations.

When it comes to reliability and high-performance motion control in automotive and industrial systems, KOYO automotive bearings stand out as a trusted solution for engineers and manufacturers worldwide. Designed to meet the rigorous demands of modern vehicles and industrial machinery, KOYO bearings deliver exceptional durability, precision, and efficiency—ensuring smooth operation even under extreme conditions.

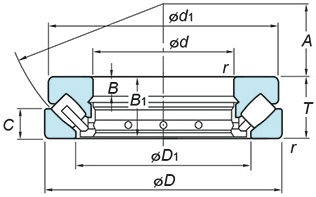

In demanding industrial and automotive applications where heavy axial loads, misalignment, and harsh operating conditions are common, **KOYO Spherical Thrust Roller Bearings** deliver unmatched reliability and performance. Engineered with precision and durability in mind, these specialized bearings are designed to accommodate high axial forces while compensating for shaft misalignment, making them indispensable in heavy machinery, power transmission systems, and precision equipment.

In the realm of precision motion control and compact machinery design, KOYO’s **K Series Super Thin Section Ball Bearings** stand out as a benchmark for high-performance, space-saving bearing solutions. Engineered to deliver exceptional rigidity, smooth operation, and minimal weight, these bearings are specifically designed for applications where conventional bearings would introduce unnecessary bulk without compromising on load capacity or rotational accuracy.

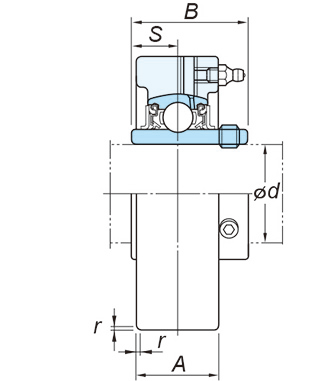

KOYO ball bearing units are engineered to deliver exceptional reliability, high-speed performance, and long service life in demanding industrial and automotive applications. As a trusted name in motion control solutions, KOYO combines advanced materials, precision manufacturing, and innovative design to produce bearing units that excel under heavy loads, extreme temperatures, and harsh operating conditions. These units are integral to machinery where smooth rotation, minimal friction, and low maintenance are critical for operational efficiency.

In demanding industrial and automotive applications where axial loads and precision motion control are critical, KOYO thrust ball bearings deliver unmatched reliability and performance. Engineered to accommodate high axial forces while minimizing friction, these bearings are designed for durability, efficiency, and seamless integration into heavy-duty machinery, automotive systems, and precision equipment. With KOYO’s decades of expertise in bearing technology, their thrust ball bearings stand out for their advanced materials, precision manufacturing, and adaptability to harsh operating conditions.

In the world of industrial machinery, automotive systems, and precision equipment, bearings play a critical role in ensuring smooth operation, reducing friction, and supporting heavy loads under challenging conditions. Among the most robust and adaptable solutions available, **KOYO Spherical Roller Bearings** stand out for their superior design, exceptional load-handling capabilities, and reliability in misalignment-prone environments.

In demanding industrial applications where high radial load capacity and compact design are critical, **KOYO Full Complement Type Cylindrical Roller Bearings** deliver unmatched performance and reliability. Engineered with precision and durability in mind, these bearings eliminate the need for a cage or retainer, maximizing the number of rolling elements within the raceway. This design significantly enhances load-bearing capacity while maintaining smooth operation under extreme conditions.

In the world of industrial machinery, automotive systems, and precision equipment, KOYO needle roller bearings stand out as a critical solution for applications requiring compact design, high load capacity, and exceptional durability. Engineered with precision and reliability in mind, these bearings are designed to operate efficiently in constrained spaces while handling significant radial loads—making them indispensable in industries where performance and space optimization are paramount.

In the demanding world of industrial machinery, automotive systems, and precision equipment, the reliability of rotating components is critical. KOYO, a globally recognized leader in bearing technology, delivers exceptional performance with its advanced **tapered roller bearings**, engineered to handle heavy radial and axial loads with unmatched efficiency. Designed for durability, precision, and smooth operation, KOYO tapered roller bearings are the preferred choice for applications requiring high load capacity, rigidity, and long service life.

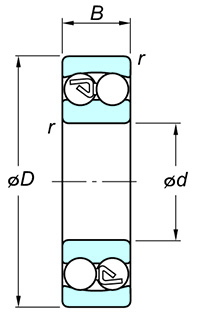

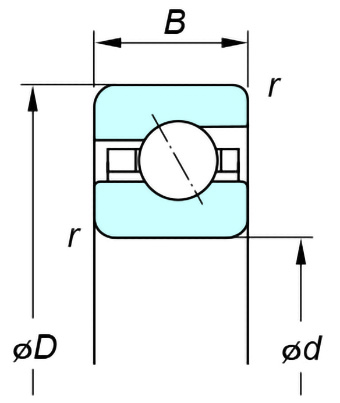

KOYO deep groove ball bearings represent a cornerstone of modern mechanical systems, offering unmatched reliability, efficiency, and performance across a broad spectrum of industrial, automotive, and precision applications. Engineered to meet the rigorous demands of high-speed operation, heavy loads, and harsh environments, these bearings combine KOYO’s decades of manufacturing expertise with advanced materials and precision design.

In the demanding world of industrial machinery, automotive systems, and precision equipment, reliability and efficiency are paramount. KOYO’s cylindrical roller bearings stand at the forefront of bearing technology, delivering unmatched performance in high-load, high-speed, and high-precision applications. Engineered with meticulous attention to detail, these bearings are designed to minimize friction, maximize load capacity, and ensure long service life—even under the most rigorous operating conditions.

In the world of high-performance rotating machinery, KOYO angular contact ball bearings stand out as a critical component for applications requiring precision, durability, and the ability to handle combined radial and axial loads. Engineered with meticulous attention to detail, these bearings are designed to deliver superior performance in industrial machinery, automotive systems, and precision equipment where reliability and efficiency are non-negotiable.