INA track rollers are engineered to handle extreme radial loads while providing smooth, precise linear motion in harsh industrial environments. With specialized designs for yoke-type (KRT) and stud-type (KR) mounting, these components deliver unmatched durability in material handling, packaging machinery, and heavy equipment application.

INA Super Precision Bearings are renowned for their superior performance and reliability and are used in a wide variety of high-precision applications.

Performance Features

INA Super Precision Bearings have the following features:

Extremely low friction: These bearings are designed to provide extremely low friction, ensuring that there is no additional noise, vibration or heat when running machines at high speed and precision

INA roller clutches revolutionize motion control by enabling instant torque transmission in one direction while allowing zero-resistance overrunning in the opposite direction. Utilizing precision-ground ramps, spring-loaded rollers, and optimized wedge geometry, these clutches deliver fail-safe engagement with <0.1° backlash—critical for applications requiring bidirectional control like helicopter rotors, conveyor indexing, and automotive starters.

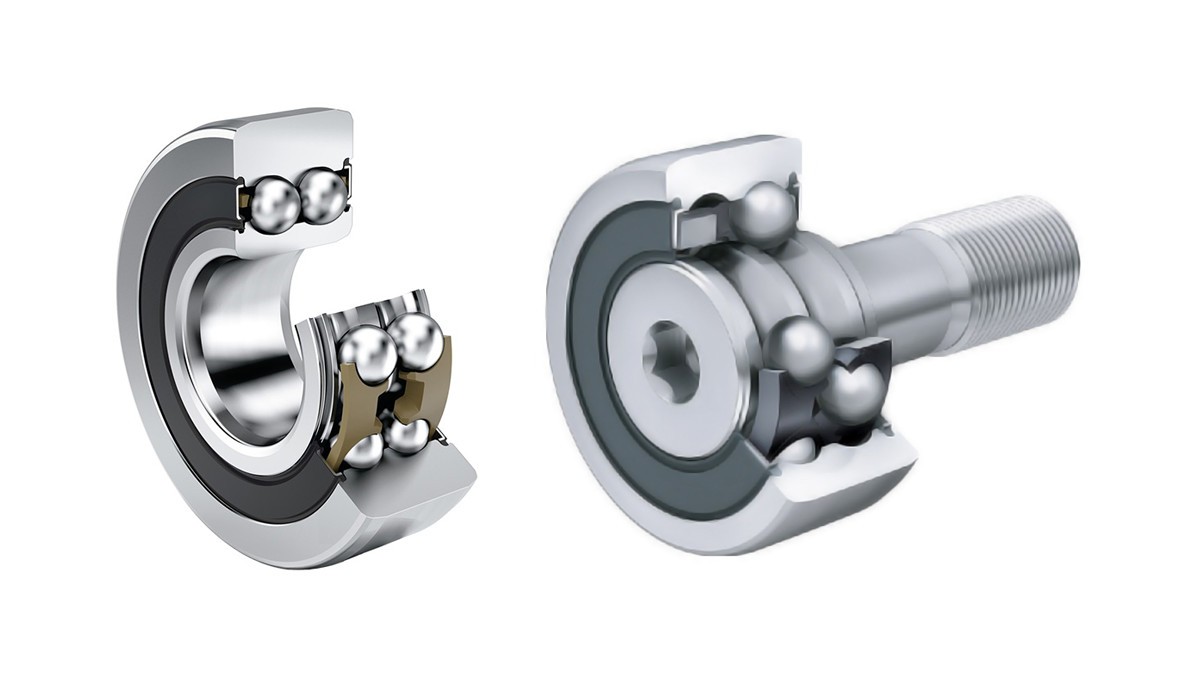

INA combined axial and radial bearings are bearings that can support both radial and axial loads. The design of these bearings is characterized by a structure that ensures good support and stability in both axial and radial directions.

Structural features and working principle

The structural features of the INA combined axial and radial bearing include:

Bearing ring: The bearing ring of the radial bearing is fixed to the axial end through the mounting hole of the axial bearing.

As a core technology within the Schaeffler Group portfolio, INA Plain Bearings redefine reliability in applications requiring silent operation, shock absorption, and contamination immunity. Unlike rolling-element bearings, INA's plain bearings leverage advanced polymers, composites, and specialty metals to deliver maintenance-free performance in harsh environments—from automotive suspensions to construction equipment and food processing machinery.

Product Taxonomy

INA roller bearings are a type of bearing with specific structural and application characteristics. They are mainly used to withstand heavy loads and impact loads. They are widely used in metallurgy, rolling mills, mining, petroleum, papermaking, cement, sugar pressing and other industries.

As an integral component of the Schaeffler Group's motion technology portfolio, INA Accessories deliver engineered solutions that extend bearing lifespan, enhance operational reliability, and streamline maintenance across industrial, automotive, and renewable energy applications. Designed to work synergistically with INA bearings, these accessories transform standard components into intelligent, high-performance systems.

Industry-Specific Solutions

INA Ball Bearings, produced by the renowned Schaeffler Group, are engineered to deliver outstanding performance, precision, and durability in a wide range of mechanical systems. These high-quality ball bearings are widely used in industrial automation, automotive applications, agricultural machinery, and precision instruments where smooth rotation and minimal friction are essential.。