FAG Super Precision Bearings are high-precision bearings produced by FAG of Germany. Their precision is as high as P4S level, far exceeding the general bearing precision standards such as DIN/ISO or ABEC. FAG high-precision bearings can meet the most stringent needs in many industries and show excellent performance. FAG Super Precision Bearings have the following characteristics: High Precision: Precision up to P4S level, meeting the needs of high-precision applications. Long Life: The use of high-quality materials and exquisite manufacturing technology significantly extends the service life. Excellent Performance: Excellent performance in harsh environments such as high speed, high temperature, and heavy load, reducing noise, vibration and heat generation These bearings are widely used in high-precision machine tools, precision instruments, aerospace and other fields to ensure stable operation and efficient work of equipment.

FAG roller bearings are a series of high-quality bearing products produced by the famous German bearing brand FAG, which are widely used in various industrial fields. FAG roller bearings mainly include tapered roller bearings, spherical roller bearings and drum roller bearings.

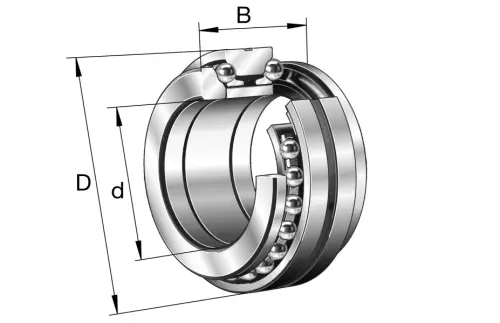

FAG ball bearings are a well-known bearing brand under the German Schaeffler Group, known for its excellent quality, high-precision manufacturing standards and wide range of applications. FAG ball bearings mainly include the following categories:

Deep groove ball bearings : This type of bearing is designed with a continuous groove raceway, mainly bearing radial loads, and can also handle certain axial loads. It has a small friction coefficient, high speed, simple structure and low manufacturing cost, and is easy to achieve high precision. The commonly used cage is a stamped wave shape. For bearings with an inner diameter of more than 200mm or high-speed operation, a machined solid cage is used.

FAG Accessories, As a pioneer in bearing technology since 1883, FAG Accessories—a core brand of the Schaeffler Group—delivers precision-engineered solutions to enhance the performance, durability, and maintenance efficiency of rotating machinery. Designed to complement FAG bearings, these accessories are trusted across industries for their innovation, reliability, and adaptability. This guide explores FAG’s comprehensive accessory range, empowering businesses to minimize downtime, reduce costs, and future-proof operations.