Bearings are the heart of smooth machine operation, and IKO Bearing Inner Rings play a critical role in this process. These inner rings are essential components in roller bearings, which provide a stable surface for moving rollers. Without precision IKO inner rings, even the best bearings cannot perform firmly. IKO produces a globally recognised brand, inner rings designed for accurate, durable and long-term performance.

Why Choose IKO Inner Rings for Industrial Applications

IKO bearing inner rings are specifically designed to meet the rigorous demands of industrial use. Machines in factories, motor vehicle production lines and heavy equipment require bearings that can handle high loads and maintain long-term stability. IKO inner rings provide reliability due to their accurate engineering and high-quality materials.

Using high-quality bearing inner rings ensures the smooth operation of the roller bearing, reducing friction and decreasing wear on other IKO roller bearing components. This not only expands the lifetime of the effect but also reduces the cost of machine downtime and maintenance. Industries like motor vehicles, agriculture, energy and construction are greatly benefit by these properties, making IKO a reliable option for industrial applications.

The compact design of these inner rings allows engineers to adapt space in machinery. This is particularly important in modern industrial machines where every millimetre matters. The combination of durability, compactness and accuracy suits IKO inner rings for a wide range of industrial uses.

High-Quality IKO Bearing Inner Ring Available

Precision engineering for reliable performance

The IKO bearing inner ring is an essential component in the system, designed to ensure smooth and accurate rotation. These inner rings are engineered with accuracy to provide stable support for rollers and cages. Using proprietary piece techniques, the IKO achieves the ico-level geometric stability, which helps in reducing friction and works efficiently under various loads.

Customized load distribution

One of the major benefits of Industrial IKO inner rings is their ability to move the load equally. They distribute stress in bearing, prevent wear and increase the lifetime of both effects and machinery. This makes them ideal for applications that require long-term stability and high reliability.

Ease of compatibility and use

IKO inner rings are designed to integrate with IKO rollers and cages. Their accurate dimensions make the installation easier and reduce the possibility of misleading. This ensures that bearings perform continuously from the moment they are installed.

Application of industries

These high-quality inner rings are widely used in industries such as industrial machinery, robotics, automotive and other equipment. They provide smooth operations, reduce maintenance needs, and improve overall machine performance.

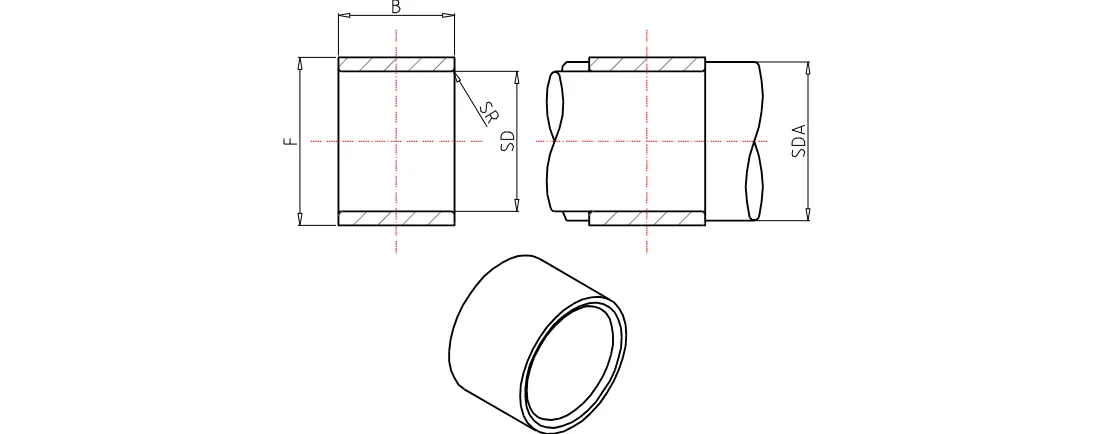

Major features of the IKO bearing Inner Ring

IKO bearing Inner Rings are known for many major features that distinguish them from ordinary components. First, they are made of high-quality steel, ensuring strength and durability under heavy loads. This allows bearings to operate smoothly even under demand.

The accurate is another major feature. IKO inner rings are manufactured with micron-level tolerance, which provides accurate guidance for roller movement. It reduces precise vibration and noise, which is essential for high-speed machinery and accurate equipment.

Another important feature is resistance to wear. Steel used in IKO inner rings is treated to withstand prolonged friction and friction. It results in long-lasting performance and reduces the need for frequent replacement.

The design of these inner rings also simplifies installation and maintenance. Many IKO inner rings are produced as single units, which simplifies the assembly and ensures correct alignment with roller bearings.

Types of IKO Bearing Inner Rings

IKO offers a series of inner rings to meet various app requirements. A common type is a standard inner ring, suitable for general-purpose roller bearings. This type provides strong support and accuracy for a wide range of industrial machinery.

Another type is the Taped Inner Ring, designed to fit taped roller bearings. This design helps to handle both radial and axial loads efficiently, making it ideal for motor vehicle applications and heavy-duty machines.

IKO also produces a custom inner ring for special equipment. These rings can be sewn to size, material and tolerance to meet unique requirements. Custom inner rings are often used in high-collection machinery such as robotics, medical devices and aerospace applications.

Each type of inner ring is designed to maintain alignment and reduce friction, ensuring that the effect is smoothly operated in various load conditions. Choosing the correct type depends on the effect type, the position of the load and the machine requirements.

How Inner Rings Support Roller Bearings

The IKO load-transfer bearing rings are an important component in a roller bearing. It acts as a surface on which rollers run. Without a properly engineered inner ring, rollers cannot move smoothly, which will increase friction and wear.

IKO bearing inner rings provide a stable and accurate path to roller movement. Their design ensures that the rollers are stationed correctly, even under heavy loads or high-speed operations. This stability improves the overall performance of the bearing and helps prevent machine failures.

The inner ring also distributes the load evenly in the rollers. By reducing stress concentrations, they prevent premature wear and extend the life of the bearing. This is particularly important in high-load applications, such as industrial machinery or motor vehicle equipment, where the inner ring must continuously support important forces.

How to select the right IKO inner ring

The correct IKO Bearing Inner Ring requires several factors to consider to choosing the inner ring.

Determine the load requirements of your application. You have to know that the effect will have to face a light, medium or heavy load. Durable IKO bearing parts are available in various sizes and powers to meet various load demands.

Consider the required accuracy and tolerance. High-speed or precise machinery requires inner rings with tight tolerances for precise roller guidance. For low-demand applications, standard tolerance inner rings may be sufficient.

The operating environment is another factor. Machines in contact with excessive temperature, dust or moisture require inner rings designed to withstand these conditions. IKO provides inner rings with extended durability and surface treatment to handle the rigid environment.

Consider the bearing type. The inner ring must match the roller bearing, intended for this, whether cylindrical, thin or roller types are crossed. Choosing the right IKO inner ring for machinery ensures smooth operation, low wear and long-term performance.

Where to Buy Authentic IKO Bearing Inner Rings?

When buying IKO Bearing Inner Rings, authenticity is crucial. Actual IKO products guarantee accurate, durability and long-term reliability. Noks is a reliable supplier that provides high-performance bearing solutions to customers worldwide.

With years of experience, they specialise in globally recognized brands such as SKF, FAG, Ina, NSK, NTN, Koy, IKO, Timken, THK and many more premium bearings and accessories. We provide products for a wide range of industries, including motor vehicle, industrial machinery, agriculture, energy and construction.

They are committed to more than the supply of products only. We provide customers to get the best solutions for their needs to provide technical support, rapid delivery and long-term value. By selecting Noks, you may be convinced that you are providing an inner ring to the actual IKO that firmly meets the demand for applications.