AG Retainers & Locking Assemblies: Precision Security for Critical Bearing Systems

Engineered Locking Solutions to Prevent Axial Displacement in Extreme Operating Conditions

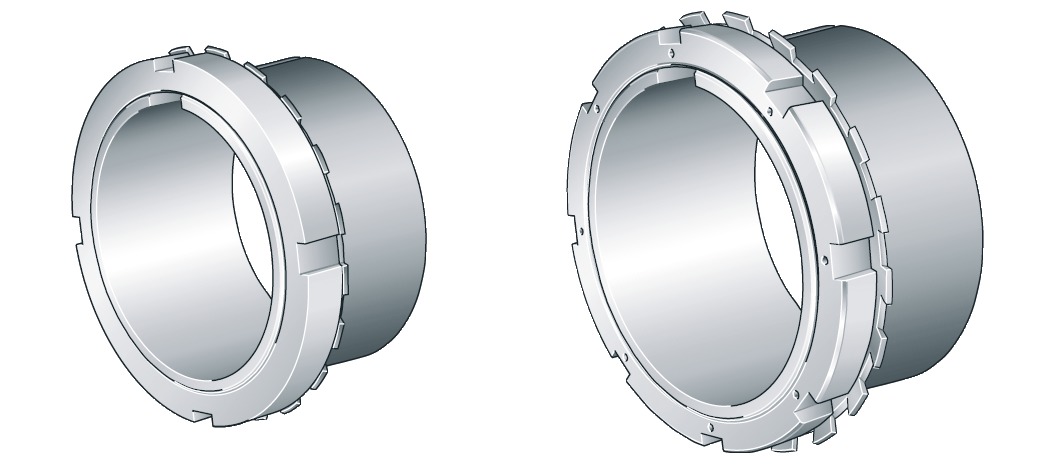

As integral components of Schaeffler Group’s power transmission security system, FAG Retainers and Locking Assemblies deliver fail-safe axial fixation for bearings subjected to high vibration, shock loads, and thermal cycling. Designed to ISO 12132-1 standards, these accessories prevent costly shaft slippage in industries where bearing displacement risks catastrophic failure – from wind turbine gearboxes to mining crushers and high-speed compressors.

As a critical component of Schaeffler Group’s power transmission ecosystem, FAG Withdrawal Sleeves redefine bearing maintenance by enabling rapid, damage-free mounting and dismounting of tapered bore bearings. Designed to withstand extreme mechanical stress while ensuring micron-level accuracy, these sleeves are indispensable in wind energy, mining, and heavy machinery applications where operational downtime is costly.

As a cornerstone of Schaeffler Group’s bearing mounting ecosystem, FAG Adapter Sleeves deliver uncompromising reliability in converting cylindrical shafts to precision tapered seats for radial bearings. Designed to ISO 246:2015 standards, these sleeves eliminate machining costs while enabling micron-level concentricity in industries where vibration and thermal cycling threaten secure fits—from wind turbine generators to steel mill conveyors and mining crushers.

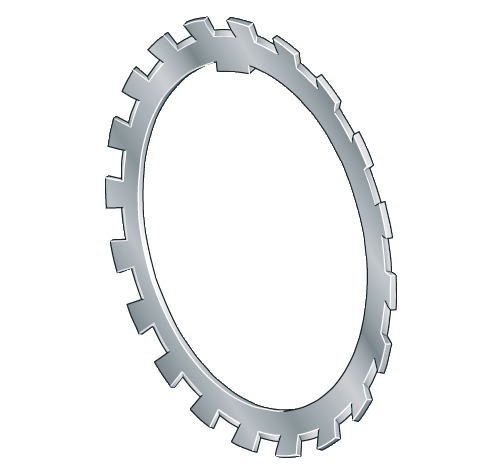

FAG shaft nuts are high-precision locking components designed to secure bearings onto shafts with maximum reliability. Manufactured by Schaeffler Group, these nuts ensure axial fixation, prevent loosening under vibration, and maintain optimal preload in critical applications such as wind turbines, industrial gearboxes, and heavy machinery.

As a leader in precision engineering, FAG (a Schaeffler Group brand) offers a complete range of high-performance bearing accessories designed to optimize installation, maintenance, and operational efficiency. From locking devices to lubrication systems, FAG accessories ensure maximum bearing lifespan, reduced downtime, and seamless integration across industries such as wind energy, mining, automotive, and industrial automation.

Axial bearing washers form the running surfaces of axial needle roller bearings and axial cylindrical roller bearings. They can also be ordered separately and combined with axial needle roller and cage assemblies or axial cylindrical roller and cage assemblies.

FAG axial bearing washers are critical components designed to optimize load distribution, reduce friction, and enhance the performance of thrust bearings in high-load applications. Manufactured by Schaeffler Group, these washers ensure precise axial alignment, minimize wear, and extend bearing service life in industries such as wind energy, heavy machinery, and industrial automation.

Key Benefits of FAG Axial Bearing Washers