Keep your shafts smooth and strong for a long time. Our premium SKF wear sleeves give shafts a fresh new look, allowing them to work like new. The sleeve is thin, light and quick to use.

Shafts deal with dust, dirt, heat, heavy work, and long hours every day. All these things slowly scratch the surface, making it rough. When the seal comes into contact with a rough or damaged spot, it can no longer retain oil effectively. This leads to leaks, hot parts, seal damage, and sudden machine stops. SKF wear sleeves makes the whole job much easier and lighter. seal surface right away. fits snugly.

Worn shafts make seals leak, waste oil, and stop machines without warning. SKF wear sleeves, fix these issues quickly with minimal effort. Here is why people like using them.

This sleeve is a great choice for a strong and safe cover for shafts that are about 63.5 mm in diameter. Because of its wide, calm, and stable shape, it stays perfectly still and undisturbed. Putting it on is easy, and it fits snugly but comfortably on the shaft. The machine runs at full capacity every day, but it greatly reduces wear and keeps the seal secure for a long time. The sleeve isn't hard to wear because it's not heavy and keeps its shape.

This sleeve fits shafts that are 64.92 mm to 65.07 mm wide and wraps tightly, neatly, and securely around them. It protects them from dirt and wear and tear. It protects the shaft by covering it with a soft and hard coating that keeps it smooth for longer and slows down wear. It's easy to set up because it's small and easy to carry. It keeps the shaft from getting worn out from regular use and small dings and scratches.

This sleeve fits snugly on shafts that are about 60.33 mm in diameter, and it gives you a clean, comfortable grip right away. Because of its small size, it slides on in just a few seconds with very little effort. The wide grip keeps dust, dirt, and other particles away from the seal, which keeps your machine clean. Because it is light, it doesn't put any extra stress on the parts, which helps the machine run quietly and efficiently.

This sleeve is a good choice for shafts that are about 69.85 mm in diameter. Its wide front makes it easier to keep dust and dirt from getting on the shaft, and it offers deep, strong protection. The machine's huge outside protects it well, no matter how hard the job is or how long it runs. The width makes it fit snugly and comfortably, which is perfect for making a solid seal without any gaps

You don't have to remove the shaft or disassemble the machine. You slide the sleeve over the worn part. This saves a considerable amount of time.

The sleeves are made of AISI 304 stainless steel, which effectively resists rust, heat, and wear. The smooth face helps the seal run longer and with less trouble.

Cutting or replacing a shaft can be costly. These sleeves are significantly cheaper and prevent many lengthy repair jobs.

The sleeve can be installed with simple hand tools. No special equipment is needed. The same seal size still works.

A strong sleeve that protects shafts when they are on and off. Lessens the chance of wear and tear and makes bearings and seals last longer.

It is a strong sleeve that makes it easy to slide seals and bearings on. Provides enough protection in areas with a lot of people.

High-quality sleeves that keep shafts safe. The part lasts longer and works better.

Wear solid sleeves that are made for fitting tasks that happen often. Increases the system's efficiency while lowering the risk of shaft damage.

A sleeve that won't wear out or rub. Great for any kind of repair or maintenance work.

Sleeves that are strong and fit snugly. Shafts are safe, and damage that happens early on is less likely to happen.

It makes sure your bearings fit well. Reduces wear on surfaces, which makes machines last longer.

A smart sleeve made for doing maintenance work. Is easy to use and keeps you safe all the time.

Strong sleeves that fit a wide range of shaft sizes. Keeps machines running smoothly and cuts down on maintenance costs.

These are snug and fit well to keep you safe. Stops important parts from getting damaged and worn out.

These sleeves are made to last and can be used over and over again. Keeps the shaft safe and working well all the time.

These sleeves let you attach them correctly. Reduces damage and makes machines last longer.

Tough sleeves made for hard work environments. Keeps shafts safe and makes maintenance easier.

These are smooth and easy to put on and take off. Protects the surfaces of the shaft and lowers friction.

It is a reliable sleeve for industrial use. Put on sleeves. Reduces work delays and helps keep damage from happening.

High-quality and offer good protection. Keeps bearings in good shape and makes them last longer.

Use a heavy-duty sleeve for jobs that involve heavy loads. The machine gets stronger, and the shafts are safe.

For safe use of bearings, sleeves must fit properly. Reduces wear and tear on equipment and makes sure it works at its best.

Lasts a long time and is very resistant to wear. Good for regular maintenance and repairs.

Reliable sleeves that fit snugly for work that needs them to. Helps keep surfaces from getting damaged and lowers repair costs.

High-quality and offer good protection. Keeps bearings in good shape and makes them last longer.

Sleeves that are strong and will last. Simple to use and gives the shaft good protection.

Both types give a smooth, strong, and long‑lasting surface for seals. Regardless of the size of your shaft, SKF has a sleeve that suits your needs.

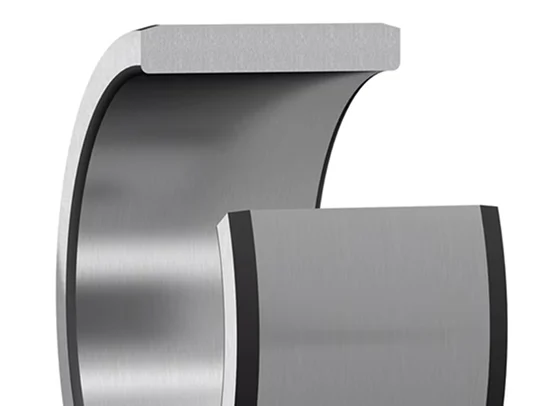

These thin sleeves (about 0.28 mm) are made from strong stainless steel. They fit shafts up to 203 mm in diameter. You can choose flanged or non‑flanged types. Their slim shape allows you to use the same seal size without any changes. SKF offers a wide range of sizes, allowing you to find one that fits perfectly.

These are designed for large shafts exceeding 8 inches (203 mm). They utilise thicker stainless steel and are intended for use in heavy, dirty, or harsh work environments. They fit shafts up to around 1,150 mm. You can choose between flanged (LDSLV3) and non-flanged (LDSLV4) options. Each one is made to order and works well for long, demanding jobs.

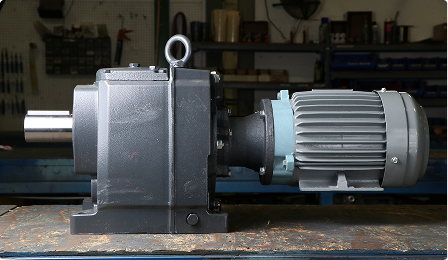

Large SKF wear sleeves in places such as mills, mines, steel plants, and cement factories face extremely harsh conditions. Dust, grit, heat, and load can quickly harm the shaft. SKF LDSLV sleeves are designed to withstand these harsh conditions. They accommodate huge shafts and can be manufactured in custom sizes and lengths to meet your exact needs. They help you avoid the enormous cost and lengthy time required to rebuild large shafts or gearboxes. keeps large machines stable, smooth, and less likely to stop.

Finding the right SKF wear sleeves is simple with our online tool. Enter your shaft size and describe the type of wear you observe. The tool provides a list of sleeves that match your shaft, along with their prices and lead times. You can compare sizes, check details, and pick the best option quickly. This eliminates guesswork, saves time, and makes the choice easy. If you need assistance at any time, our support team is available to guide you.

These machines operate for extended periods and frequently cause scratches on the shaft surface. A sleeve provides the seal with a clean, smooth surface and prevents leaks.

These machines face dust, dirt, bumps, and shocks. Sleeves can be installed on‑site to keep work moving.

These machines handle dust, fluids, and operate over extended periods. A sleeve gives a rigid surface that helps cut leaks and wear.

Big shafts face heat, force, and dirt every day. LDSLV sleeves help protect them and keep seals working.

Prop shafts and generators utilise sleeves to prevent lengthy and costly repair work.

When a shaft starts to wear down, it can cause numerous minor problems that worsen over time. To fix this, you have several repair options:

Choosing a new shaft or undergoing a full rebuild takes the most time and incurs the highest costs. A new shaft needs to be made from scratch, which means the machine must stop working until it arrives.

This option costs less than purchasing a new shaft but still requires a significant amount of time, care, and skill. The machine must be taken apart, the shaft must be removed, and then it must be sent to a workshop.

This is often the quickest and lowest‑cost repair. You do not need to remove the shaft or take apart the machine. The sleeve slides over the worn area, providing the seal with a new, smooth surface to run on.

This option is the least expensive initially, but it is only effective if the shaft damage is minimal and shallow. If the shaft has deeper marks, lines, or scratches, the new seal will start leaking again after a short time.

Type / Model

Material

Shaft Size Range

Installation Method

Typical Use

Seal Compatibility

SKF Speedi-Sleeve Standard

Stainless Steel

Small–Medium Shafts

Press-fit

Pumps, motors

Oil seals, radial seals

SKF Speedi-Sleeve Gold

Gold-coated Steel

Medium Shafts

Press-fit

Gearboxes, heavy-duty

Elastomer seals

Thick Stainless

Large Shafts

Heated or press-mounted

Industrial shafts

Large oil seals

Type / Model

SKF Speedi-Sleeve Standard

SKF Speedi-Sleeve Gold

Material

Stainless Steel

Gold-coated Steel

Thick Stainless

Shaft Size Range

Small–Medium Shafts

Medium Shafts

Large Shafts

Installation Method

Press-fit

Press-fit

Heated or press-mounted

Typical Use

Pumps, motors

Gearboxes, heavy-duty

Industrial shafts

Seal Compatibility

Oil seals, radial seals

Elastomer seals

Large oil seals

Here is an easy step‑by‑step guide to installing an SKF Speedi‑Sleeve.

Begin by thoroughly cleaning the shaft. Examine the worn area closely to determine its size. Measure the shaft to choose the correct sleeve size. Cleaning and measuring slowly and carefully helps the sleeve fit better and last longer.

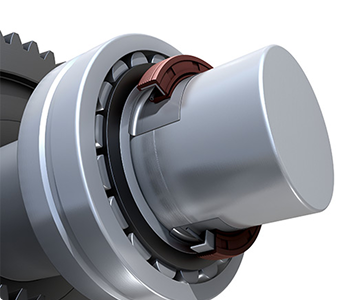

After cleaning, slide the sleeve gently onto the shaft. Ensure it does not scratch. Push it until the sleeve fully covers the worn spot. If the sleeve has a flange, ensure it remains clear and does not come into contact with any other part.

Use the installation tool provided with the sleeve, or lightly tap it with a soft mallet. Tap slowly around the edge so the sleeve moves straight and smooth. When the sleeve is in a flat position, it will remain firm and steady.

We have given you the tools you need to help you choose the right SKF wear sleeves if you need help. You can download datasheets, 3D CAD models, and full-size diagrams that show all the part numbers. Use the SKF sizing chart and catalog to help you find the right sleeve for your shaft.

If you’re not sure which sleeve to choose, please contact our engineering team for help. They can tell you what size, speed, load, shaft type, and sleeve will work best with your machine.

You can be sure that the items you buy from us are real and come with all the paperwork and support you need from the manufacturer because we are an official SKF dealer. SKF’s large global network gives you access to world-class help.

ISO 9001 and ISO 14001 set standards for quality that SKF follows. These standards make sure that their products are always of high quality and that their operations are safe. These certificates prove that SKF sleeves are made with care, tested thoroughly, and built to last.

NOKS International Trade Group Ltd. is an official and trustworthy SKF distributor. All of the sleeves we sell are real SKF products. This means they come with the right specs, all the paperwork, and direct help from SKF.

We are proud members of the Industrial Seals and Machinery Association, which is one of the most respected groups. Being a member of these groups shows that we stay up to date with the latest research and follow best practices in our field.

SKF has been making seals, shafts, and wear prevention products for over a hundred years. Many industries around the world trust SKF Speedi-Sleeves because they work well in a wide range of machines and work environments.

If you need SKF wear sleeves, NOKS International Trade Group Limited is the only place to look. Our huge selection of sleeve sizes, along with our helpful customer service and step-by-step instructions, is the best in the business. Our staff is here to help if you need help picking the right sleeve size, have questions about how to install it, or just want some tips. We charge low prices and respond quickly. We send things all over the world.

NOKS is the best place to buy SKF wear sleeves online because they sell real SKF parts, make it easy to order, and have great customer service. If you have any questions or would like a quote, please get in touch with us. We want to make sure that your devices keep working well, safely, and reliably for as long as possible.

Robot deburring equipment can deburr a wide range of materials. This group includes plastic, aluminum, steel, brass, and titanium. Robots are great at casting aluminum. Every substance needs its own special tool. Because of this, robotic deburring can be used in many different ways.

Many companies own robots that deburr things. Some of these are well-known names in robotics and automation. LongLi is a name you can trust because it is reliable and offers complete, ready-to-use solutions. Every system is made to meet your needs and goals exactly.

Yes. Automated machines can do more than just remove burrs. With just a change of tools, the same robot can grind and polish. The robot can finish smoothing surfaces after deburring with a soft pad. It might take off more material with rough wheels.

You need to put safety first. Gates, buttons, and alarms are some of the safety features that come with industrial robot cells. Collaborative robots have more sensors and are lighter. They can work near people safely with these sensors. As soon as the robot sees something in its way, it stops moving. All LongLi systems follow safety rules and requirements

Yes. LongLi’s robot deburring equipment can be used by small businesses. In these setups, small or friendly robots work together. It’s easy to set them up and understand how they work. They are cheaper and take up less space than big systems.

The right tool depends on the part and the burr. You need strong shears for complicated parts. Soft parts need sanding wheels or brushes. LongLi can help you find the right balance between tool size, power, and speed. We might also test tools to ensure they work properly before we use them.

I put a sleeve on an old motor shaft. It slid on real fast. I saw no leaks in less than a min. I kept the same seal. It saved me a full 24 hours of hard work. It felt like magic.

We slid it onto a pump shaft in our plant. The fix was smooth. The line stopped for a small bit. I just wish they had a wider edge part, but still, it was a top win.

I do fixes in the open field. No shop. No extra crew. Just hand tools. Tap it on. Swap seal. Done. The belt hub shaft ran full shift on the same work day. No oil drip. Great win.

The kit came with a small press tool. The steps were so short and easy. The whole fix was about 15–20 min. I was done before my coffee got cool. Very happy.

This sleeve saved our old press motor line. It slid on clean. It was a one-try fix for oil block. No redo. No mess. If you fix old rigs, this part is a must buy.

The seal team loves these sleeves now. We thought we may need a new seal size, but we reused the old seal. It fit fine. No leaks. Big time save. Clean finish.