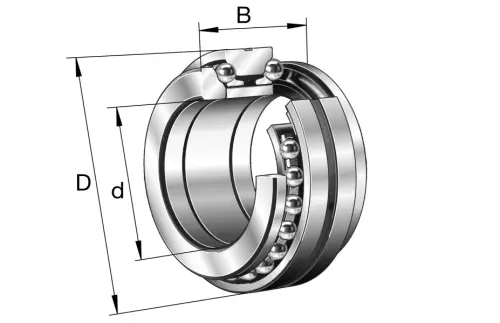

FAG's Axial-Super Precision Bearing (ASP bearing) is a high-precision bearing that is particularly suitable for applications that require high precision and high-speed performance.

Features and Applications

FAG's ASP bearings have the following features: High Precision: These bearings can provide extremely high geometric and rotational accuracy, ensuring stability and accuracy at high speeds. High-Speed Performance: ASP bearings are designed for high-speed rotation, which can reduce friction and heat generation, and improve overall performance and efficiency. High Rigidity and Anti-Seismic Performance: The bearings use high-quality materials and advanced manufacturing processes to ensure

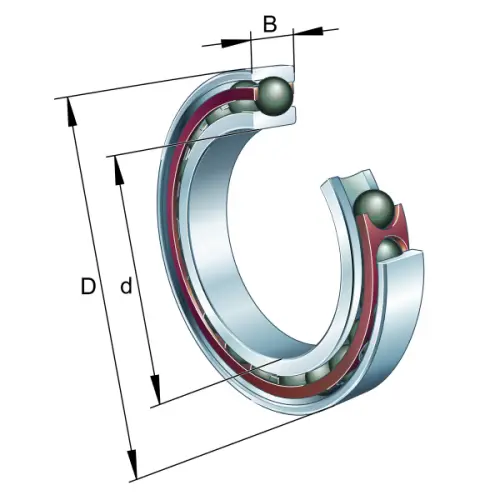

FAG's Radial Super Precision Bearing has the following features and advantages:

High Precision : FAG's Radial Super Precision Bearing has a precision of up to P4S level, far exceeding the general bearing precision standards such as DIN/ISO or ABEC. This high precision enables the bearings to meet the most stringent requirements and show excellent performance in many industries High-quality materials : FAG bearings are made of high-quality materials, such as Cronidur 30 steel. This high-nitrogen stainless steel is significantly superior to standard bearing steel in terms of metallographic structure, impact toughness, dimensional stability and hardness, thereby improving the life and performance of the bearing Excellent