INA Seals: Engineered Precision for Maximum Bearing Protection & System Reliability

Introduction: The First Line of Defense in Rotating Systems

In the demanding world of industrial machinery, bearings are the heart of motion – but their longevity hinges on effective contamination control and lubrication retention. INA Seals, engineered by the Schaeffler Group’s renowned bearing specialists, deliver critical protection where rotating shafts meet stationary housings. Far beyond generic seals, INA’s portfolio integrates cutting-edge materials, precision geometries, and system-level design to combat wear, energy loss, and premature failure. From high-speed motors to submerged pumps, these seals transform vulnerable interfaces into robust barriers, extending equipment life while reducing maintenance costs.

INA Seal Carrier Assemblies: Engineered Precision for Reliable Shaft Sealing & Bearing Protection

Introduction: The Critical Interface Between Rotating and Static Worlds

In the demanding environment of rotating machinery – from massive turbines and pumps to high-speed conveyors and agitators – preventing lubricant leakage and excluding contaminants is paramount for bearing longevity and operational reliability. While seals are the frontline defense, their effectiveness hinges on precise mounting, alignment, and robust support. This is where INA Seal Carrier Assemblies (also known as bearing isolator housings, seal housings, or cartridge seals) step in as sophisticated, pre-engineered solutions. INA, leveraging the engineering prowess of the Schaeffler

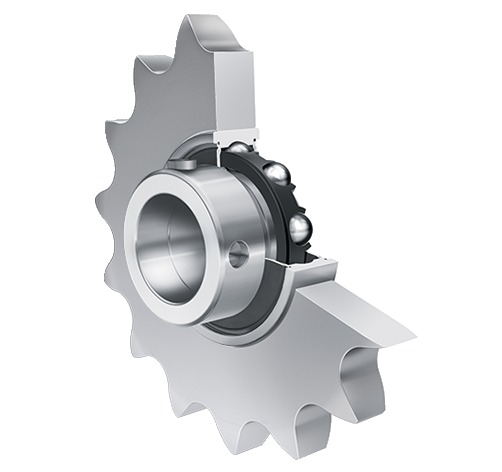

INA Roller Chain Idler Sprocket Units: Precision Chain Tensioning & Guidance for Industrial Drives

Engineered Solutions for Noise Reduction, Wear Mitigation, and Extended Chain Life in Power Transmission Systems

INA Roller Chain Idler Sprocket Units integrate hardened sprockets, sealed bearings, and robust housings into a single assembly, engineered to maintain optimal chain tension, dampen vibration, and correct alignment errors in conveyor, automotive, and heavy machinery drives. As part of Schaeffler Group’s power transmission portfolio, these units eliminate premature chain wear while operating maintenance-free under extreme loads and contaminants.

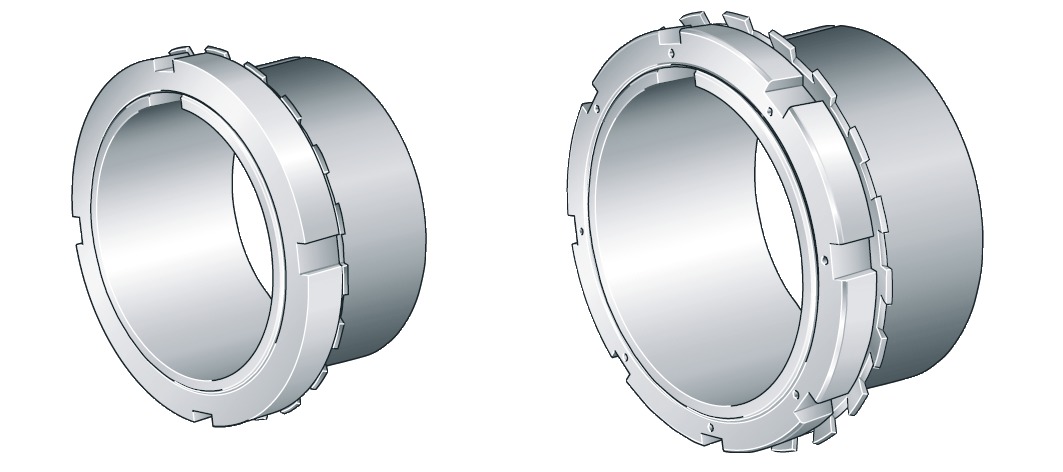

INA Precision Locknuts: The Ultimate Solution for Secure, Reliable Bearing Axial Fixation

Introduction: The Critical Role of Axial Security in Rotating Machinery

In the high-stakes world of precision rotating equipment – from electric motors and gearboxes to pumps, fans, and industrial machinery – ensuring bearings remain securely fixed in their axial position is non-negotiable. Bearing creep, slippage, or unintended axial movement under load leads to catastrophic failure, rapid wear, excessive vibration, and costly downtime. While standard nuts might suffice for low-demand applications, INA Precision Locknuts represent the pinnacle of

INA Axial Bearing Washers: Precision Interfaces for Optimal Thrust Load Transmission & Bearing Performance

Introduction: Mastering Axial Forces in Rotating Systems

In the complex dynamics of rotating machinery, managing axial (thrust) loads is as critical as handling radial loads. Bearings designed for axial loads – such as cylindrical roller thrust bearings, needle roller thrust bearings, ball thrust bearings, and tapered roller bearings (in specific configurations) – require precisely engineered interfaces to ensure correct load distribution, prevent damage, minimize friction, and guarantee long-term reliability. INA Axial Bearing Washers are specialized, high-precision components designed specifically for this purpose.

INA Adapter Sleeves: Precision Shaft Mounting Solutions for Industrial Bearing Systems

Engineered Tapered Sleeves for Secure Bearing Positioning & Simplified Maintenance

INA Adapter Sleeves represent Schaeffler Group's specialized solution for mounting radial bearings with tapered bores onto cylindrical shafts, enabling precise axial positioning, robust torque transmission, and field-replaceable bearing systems across heavy machinery, power transmission, and industrial applications. These conical sleeves transform standard shafts into optimized bearing seats without machining.

Core Engineering Principles & Design

INA Other Accessories: Essential Components for Optimized Bearing Performance & System Reliability

Introduction: Completing the Precision Puzzle

While bearings, housings, adapter sleeves, and seal carriers form the core of rotating assemblies, achieving peak performance, longevity, and reliable operation often hinges on a suite of critical supporting components. INA Other Accessories encompass this vital array of engineered parts designed to address specific mounting, fixing, lubrication, protection, and maintenance needs. These components, often underestimated, play indispensable roles in ensuring bearings function as intended within the broader mechanical system. Engineered with the same precision and quality as INA's core products, these accessories simplify installation, enhance safety, prevent failures, extend service life, and reduce total