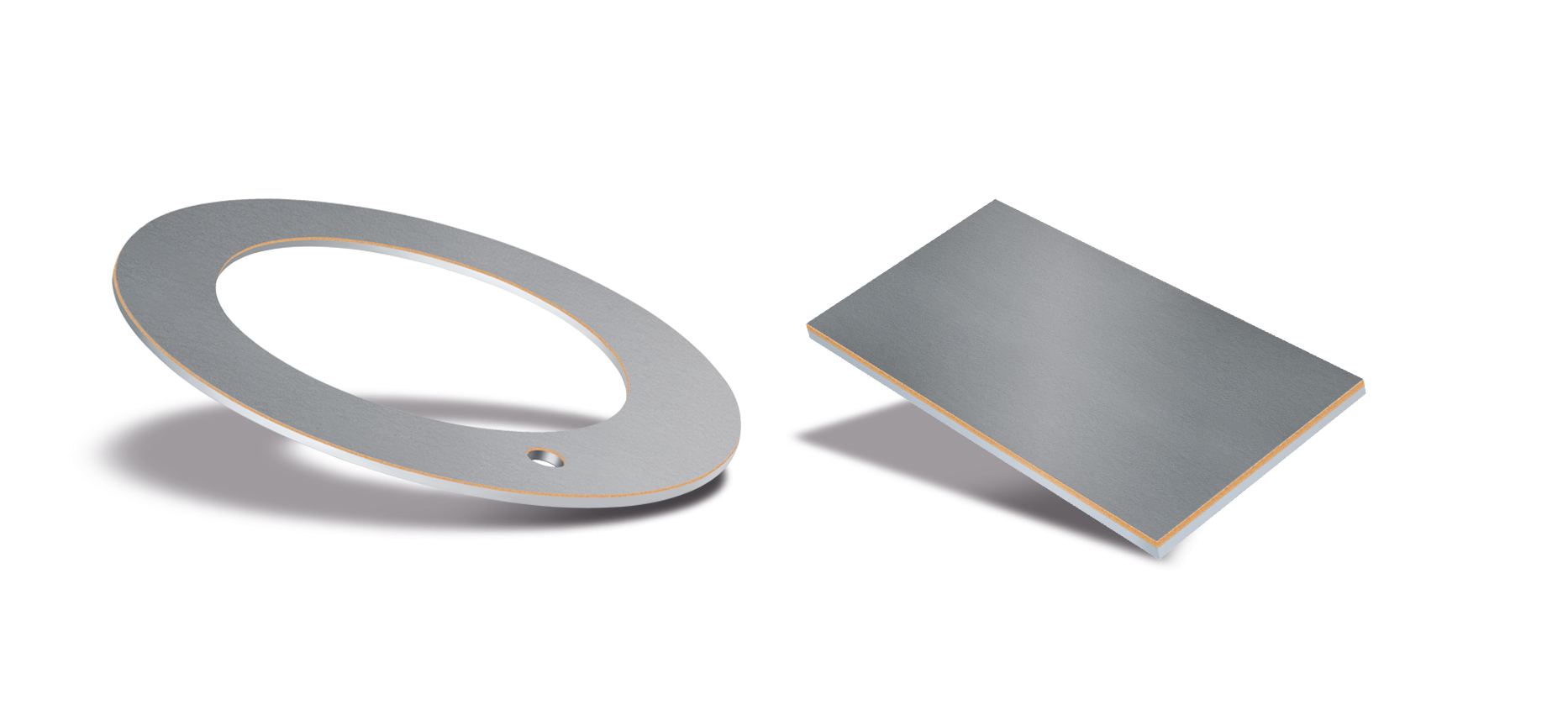

INA Thrust Washers and Strips represent Schaeffler Group's specialized solution for managing unidirectional axial loads in applications where radial space is abundant but axial height is critically constrained. These ultra-thin, self-lubricating components eliminate the need for complex thrust bearing assemblies, delivering reliable performance in gearboxes, pivots, and rotating assemblies with near-zero maintenance.

Product Forms:

INA Rod Ends (spherical plain bearings with integral rod attachments) represent Schaeffler Group's engineered solution for transferring forces and motions through articulated linkages across industries where misalignment, high loads, and harsh environments challenge conventional joints. Combining a spherical plain bearing core with threaded shanks or forged eyes, these components enable ±2°–25° angular misalignment while transmitting axial, radial, and moment loads with unmatched durability and maintenance-free operation.

Key Performance Benefits:

In the realm of precision machinery where simplicity, reliability, and cost-effectiveness are paramount, INA Plain Bushes (also known as sleeve bearings, bushings, or plain bearings) stand as indispensable workhorses. Engineered by Schaeffler Group’s INA brand, these unassuming yet highly sophisticated components facilitate smooth linear movement, rotation, or oscillation between mating surfaces without rolling elements. Designed for applications demanding low noise, high load capacity in minimal space, corrosion resistance, and often maintenance-free operation, INA Plain Bushes deliver exceptional performance across automotive, industrial, agricultural, and consumer sectors.

Key Advantages vs. Rolling Bearings:

INA Spherical Plain Bearings represent Schaeffler Group's pinnacle of sliding bearing technology, engineered to resolve the universal challenge of shaft misalignment while transmitting high radial/axial loads and tilting moments. Unlike rolling element bearings, these self-lubricating or grease-lubricated components enable ±2°–25° static/dynamic angular compensation, making them indispensable in heavy machinery, automotive systems, and aerospace applications where rigid alignment is impossible.