INA Yoke Type Track Rollers: Heavy-Duty Stability for Demanding Industrial Motion

(Technical Analysis for Bearing Catalogs & Machine Design)

I. Engineering Definition & Core Advantage

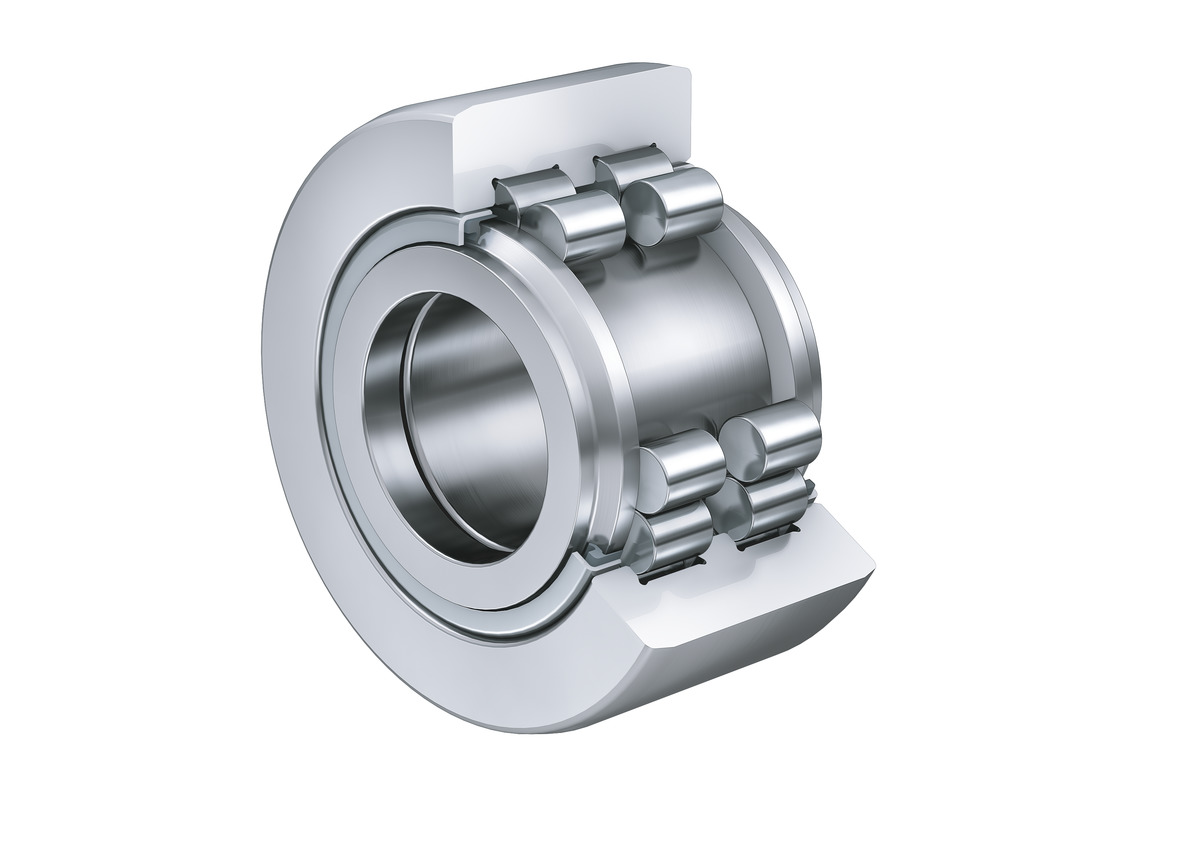

INA Yoke Type Track Rollers (clevis-type cam followers) feature a straddle-mounted yoke fork that distributes loads symmetrically across two support points. This design delivers exceptional resistance to overturning moments and edge forces – making them the premier solution when load stability outweighs space constraints. Unlike stud-type rollers, they transform bending stress into shear stress for unparalleled durability in shock-intensive applications.

INA Track Rollers: The Ultimate Guide to Yoke & Stud Type Solutions

(Technical Analysis for Industrial Bearing Catalogs)

I. Track Roller Fundamentals: Purpose & Engineering

INA Track Rollers (Cam Followers) are robust, integrated bearing systems designed to handle high radial loads while rolling along tracks, cam profiles, or guide rails. They transform sliding friction into rolling motion, enabling precision motion control in demanding environments. Key design features include:

I. Core Definition & Engineering Purpose

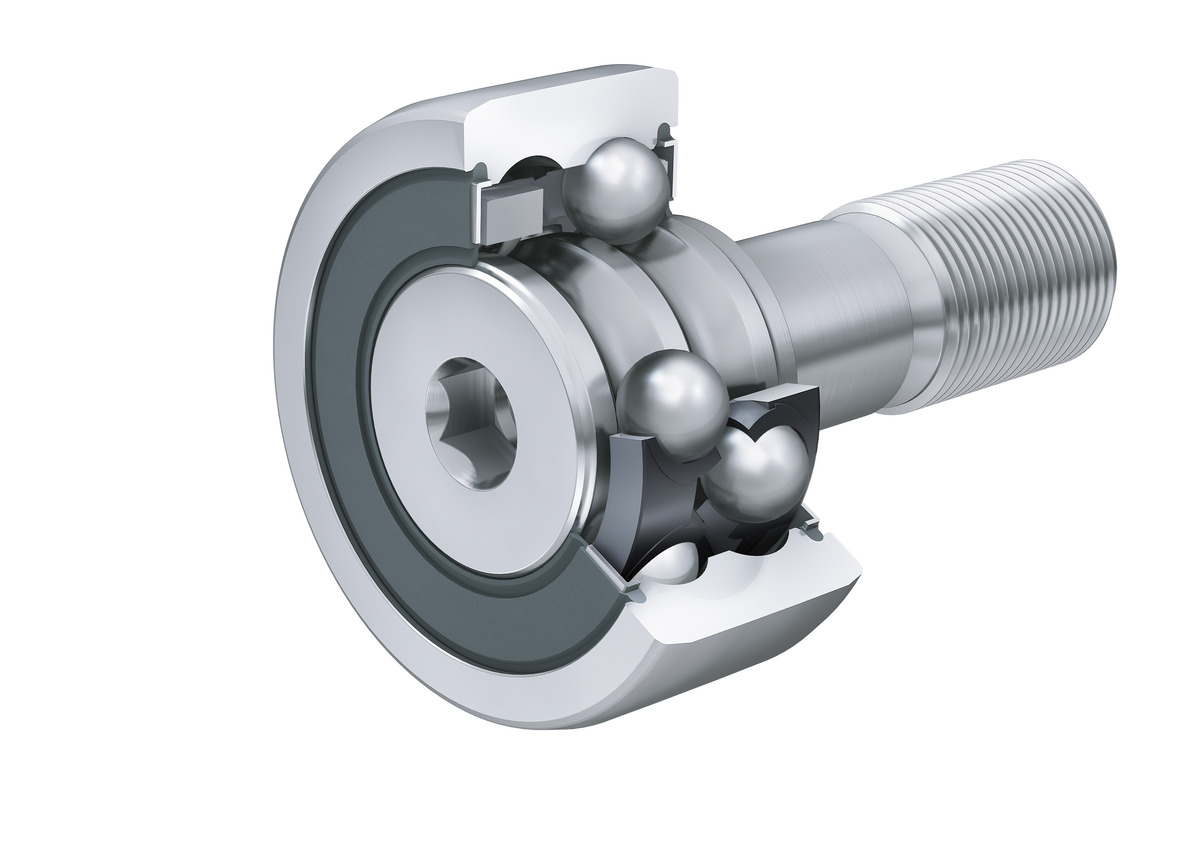

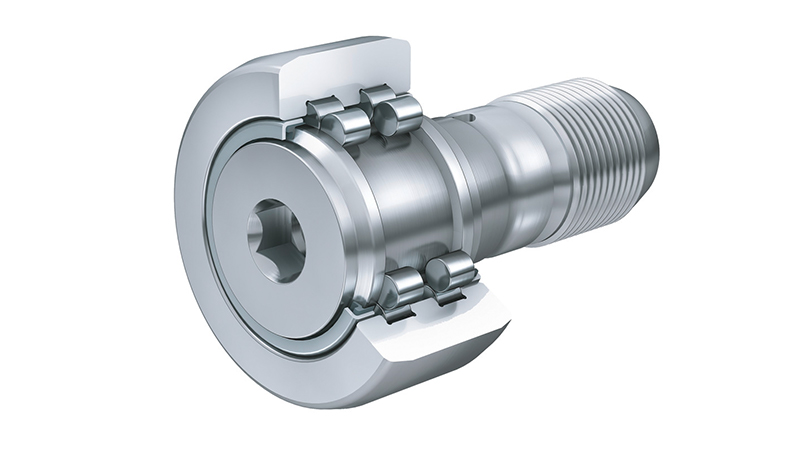

INA Stud Type Track Rollers (Cam Followers) are integrated bearing systems featuring a hardened, crowned outer ring rotating on a fixed, threaded stud shaft. Engineered to handle high radial loads in confined spaces, they provide smooth rolling contact along tracks, cam profiles, or guide rails while resisting edge forces and contamination. Unlike yoke types, their cantilever design prioritizes radial compactness over moment load capacity.

II. Design Anatomy & Key Components

For demanding applications requiring smooth, reliable guidance along tracks, rails, or cam profiles while supporting significant radial loads – often under harsh conditions – INA (a Schaeffler Group brand) offers a specialized range of Track Rollers, also widely known as Cam Followers or Cam Rollers. These robust components are engineered to handle combined rolling and sliding forces, impacts, and environmental challenges. This analysis delves into the design, variants (Yoke Type, Stud Type), features, and critical applications of INA track rollers.

I. Core Function & Design Principle