NSK is a global leader in precision motion and control solutions, delivering high-performance bearings that enhance efficiency, reliability, and longevity in demanding industrial, automotive, and precision equipment applications. Among NSK’s extensive bearing portfolio, **Deep Groove Ball Bearings** and **Magneto Bearings** stand out for their advanced engineering, superior load-handling capabilities, and adaptability to high-speed and high-precision environments. These technologies are critical to optimizing performance in applications ranging from electric motors and robotics to automotive drivetrains and medical devices.

NSK’s Extra Small Ball Bearings and Miniature Ball Bearings (Inch Series with Flange) represent the pinnacle of precision engineering, offering unmatched performance in compact, high-speed, and high-accuracy applications. Designed for industries where space constraints and reliability are critical, these deep groove ball bearings deliver smooth motion, reduced friction, and extended service life—even in the most demanding environments.

NSK’s precision motion and control technologies set the benchmark for reliability and performance in demanding applications, particularly with their **Extra Small Ball Bearings and Miniature Ball Bearings (Inch Series)**. Designed for compact, high-speed, and high-precision environments, these deep groove ball bearings deliver exceptional durability, smooth operation, and energy efficiency—critical for industries where space constraints and operational precision are paramount.

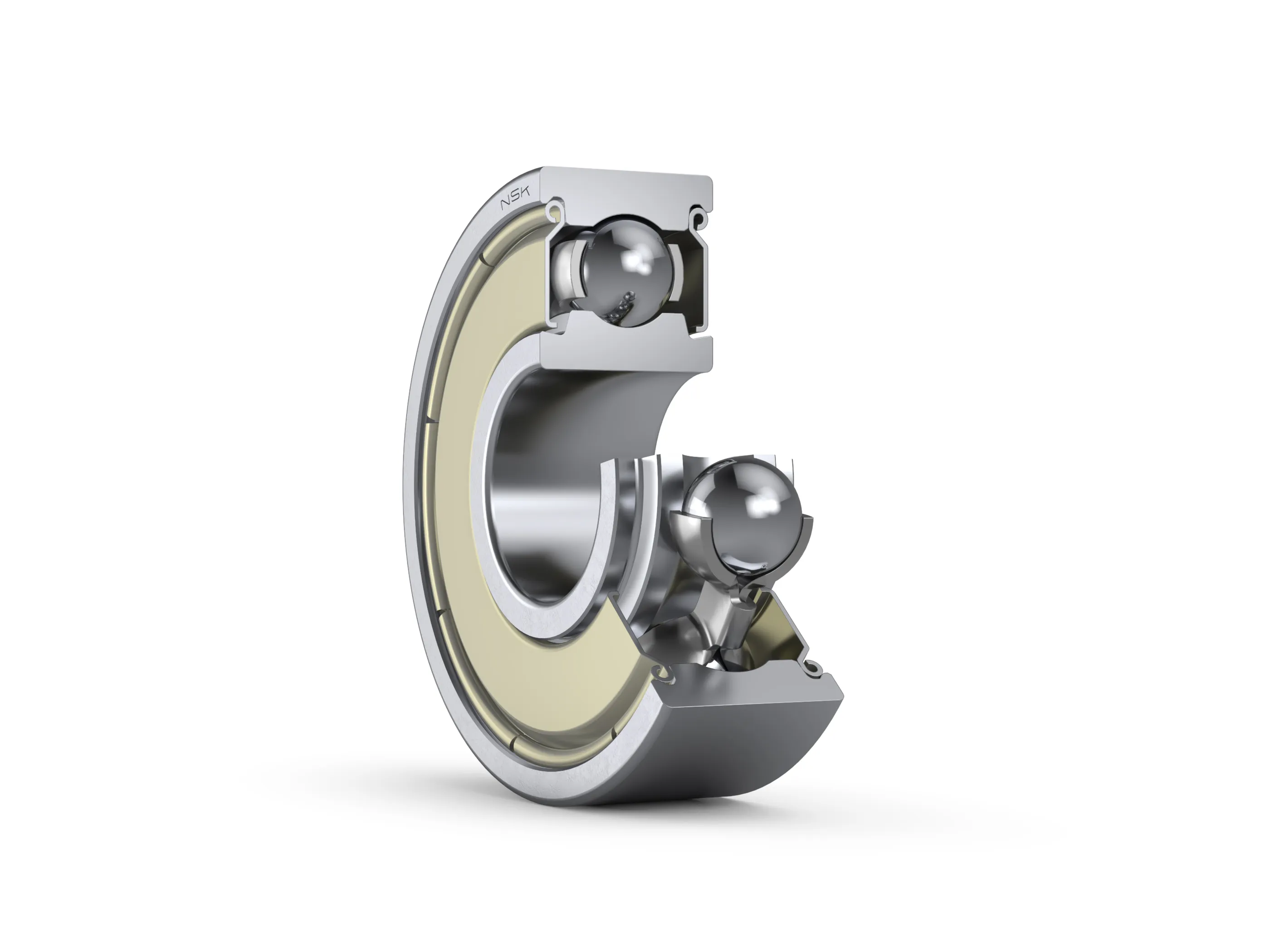

NSK is a global leader in precision motion and control technologies, renowned for engineering high-performance bearings that deliver exceptional reliability, efficiency, and longevity. Among its extensive portfolio, NSK’s **Deep Groove Ball Bearings – Maximum Type** stand out as a critical solution for demanding industrial, automotive, and precision equipment applications. These bearings are designed to optimize load capacity, minimize friction, and extend service life, even under high-speed or harsh operating conditions.

NSK’s precision-engineered **Extra Small Ball Bearings and Miniature Ball Bearings (Metric Series with Flange)** represent the pinnacle of compact, high-performance bearing technology. Designed for applications where space constraints, precision, and reliability are critical, these deep groove ball bearings deliver exceptional rotational accuracy, durability, and load capacity in demanding environments. With advanced materials, optimized geometries, and NSK’s proprietary manufacturing expertise, these bearings are ideal for industrial machinery, automotive systems, medical devices, and precision instrumentation.

NSK’s deep groove ball bearings in extra-small and miniature metric series represent the pinnacle of precision engineering, delivering unmatched performance in compact, high-speed, and high-load applications. Designed for industries where space constraints and reliability are critical, these bearings combine advanced materials, ultra-precise manufacturing tolerances, and innovative sealing technologies to ensure smooth operation, extended service life, and reduced maintenance requirements.

NSK’s Single Row Deep Groove Ball Bearings represent the pinnacle of precision motion and control technology, engineered to deliver exceptional performance, durability, and efficiency across a wide range of industrial, automotive, and precision equipment applications. As a foundational component in rotating machinery, these bearings are designed to handle radial and axial loads simultaneously, offering smooth operation, low friction, and long service life even under demanding conditions.