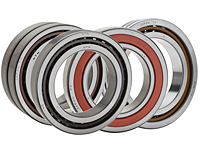

NTN Corporation, a global leader in bearing technology, delivers exceptional performance with its range of **Angular Contact Ball Bearings**, designed to meet the rigorous demands of industrial machinery, automotive systems, and high-precision equipment. These bearings are engineered to handle combined radial and axial loads with superior accuracy, durability, and efficiency, making them indispensable in applications where precision, speed, and reliability are critical.

NTN Corporation, a global leader in bearing technology, offers a comprehensive range of high-precision **Angular Contact Ball Bearings** designed to meet the demanding requirements of industrial machinery, automotive systems, and precision equipment. These bearings are engineered to accommodate combined radial and axial loads while maintaining exceptional accuracy, rigidity, and speed performance. Among NTN’s specialized offerings are **Precision Angular Contact Ball Bearings** and **Angular Contact Thrust Ball Bearings for Ball Screws**, which are critical for applications requiring ultra-precise motion control and high load capacity.

NTN Corporation, a global leader in bearing technology, offers an exceptional range of **Angular Contact Ball Bearings** designed to meet the rigorous demands of industrial machinery, automotive systems, and precision equipment. These high-performance bearings are engineered to handle **combined radial and axial loads**, making them indispensable in applications requiring **high-speed operation, rigidity, and precise rotational accuracy**. Whether used in **electric motors, machine tool spindles, lathes, or automotive drivetrains**, NTN’s Angular Contact Ball Bearings deliver unmatched reliability and efficiency.

NTN Corporation, a global leader in bearing technology, delivers unmatched precision and reliability with its range of **Angular Contact Ball Bearings**, designed to handle high axial loads, radial loads, and combined loads in demanding applications. These bearings are engineered to meet the rigorous demands of industrial machinery, automotive systems, and precision equipment, ensuring optimal performance, extended service life, and reduced maintenance costs.

NTN Corporation, a global leader in bearing technology, delivers exceptional performance with its advanced line of **Angular Contact Ball Bearings**, designed to meet the rigorous demands of industrial machinery, automotive systems, and precision equipment. These bearings are engineered to handle combined radial and axial loads while maintaining high-speed capability, accuracy, and durability. NTN’s precision-engineered solutions include **Standard Angular Contact Ball Bearings, Precision Angular Contact Ball Bearings, and High-Speed Angular Contact Ball Bearings**, each optimized for specific operational requirements.

NTN Corporation, a global leader in bearing technology, offers a comprehensive range of high-performance **Angular Contact Ball Bearings**, designed to meet the demanding requirements of industrial machinery, automotive systems, and precision equipment. Among NTN’s extensive portfolio, **Single Row Angular Contact Ball Bearings** stand out for their ability to handle combined radial and axial loads while maintaining exceptional precision, durability, and rotational accuracy. These bearings are engineered to optimize performance in high-speed applications, ensuring reliability in even the most challenging operating conditions.

When precision, durability, and high-speed performance are critical, NTN’s **Angular Contact Ball Bearings** stand out as a trusted solution for demanding industrial, automotive, and precision equipment applications. Specifically designed to handle combined radial and axial loads, these bearings excel in environments where accuracy, rigidity, and low friction are essential. The **NTN Machline series** of precision angular contact ball bearings further enhances these capabilities, offering superior engineering for high-performance machinery, machine tools, and automotive systems.