NTN Corporation, a global leader in bearing technology, offers high-performance **Self-Aligning Needle Roller Bearings** designed to deliver exceptional reliability, reduced friction, and superior load-carrying capacity in compact spaces. These bearings are engineered to accommodate misalignment between shafts and housings—a common challenge in industrial machinery, automotive systems, and precision equipment—while maintaining optimal performance under high radial loads.

NTN’s **Clearance Adjustable Needle Roller Bearings** represent a high-performance solution designed to meet the rigorous demands of industrial machinery, automotive systems, and precision equipment. Engineered for applications where precise radial clearance control is critical, these bearings combine NTN’s advanced needle roller technology with innovative adjustability, ensuring optimal performance, extended service life, and reduced maintenance requirements.

NTN’s needle roller thrust bearings are precision-engineered components designed to deliver exceptional load capacity, durability, and efficiency in applications where axial loads and space constraints are critical factors. These bearings are a key part of NTN’s extensive portfolio of rolling bearings, offering specialized solutions for industrial machinery, automotive systems, and precision equipment. By incorporating advanced materials, optimized geometries, and superior manufacturing techniques, NTN ensures reliable performance even in the most demanding operating conditions.

In the world of high-performance bearings, NTN stands as a leader in innovation and reliability, offering advanced **needle roller bearings** and **complex bearing solutions** designed to meet the rigorous demands of industrial machinery, automotive systems, and precision equipment. NTN’s needle roller bearings are engineered to deliver exceptional load capacity, compact design efficiency, and long service life—even in the most challenging operating conditions.

NTN is a globally recognized leader in the design and manufacture of high-performance rolling bearings, and its **Needle Roller Bearings – Roller Followers** stand out as a critical solution for applications demanding compact design, high load capacity, and smooth motion control. Engineered to withstand heavy radial loads while minimizing friction, these precision components are widely used in industrial machinery, automotive systems, and precision equipment where reliability and efficiency are paramount.

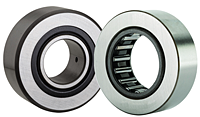

NTN needle roller bearings with inner rings are engineered to deliver exceptional performance in high-load, high-speed, and space-constrained applications. Designed with precision and durability in mind, these bearings combine compact design with robust load-carrying capabilities, making them ideal for demanding industrial machinery, automotive systems, and precision equipment.

NTN’s **Machined Ring Needle Roller Bearings** represent a pinnacle of engineering excellence, offering superior performance in compact, high-load applications where space constraints and reliability are critical. Designed with precision-ground rings and high-quality needle rollers, these bearings deliver exceptional durability, reduced friction, and enhanced load-carrying capacity—making them ideal for industrial machinery, automotive systems, and precision equipment.

NTN’s **Drawn Cup Needle Roller Bearings** represent a high-performance solution for applications demanding compact design, high load capacity, and smooth rotational performance. Engineered with precision, these bearings are a critical component in industrial machinery, automotive systems, and precision equipment where space constraints and reliability are key considerations.

NTN is a global leader in bearing technology, renowned for its high-performance needle roller bearings and needle roller and cage assemblies. These precision-engineered components are designed to deliver exceptional load capacity, durability, and efficiency in compact spaces, making them indispensable in industrial machinery, automotive systems, and precision equipment.

NTN is a globally recognized leader in the design and manufacture of high-performance rolling bearings, and its **Needle Roller Bearings Cam Followers** are among the most reliable and efficient solutions for motion control in industrial machinery, automotive systems, and precision equipment. Engineered to withstand high loads, reduce friction, and ensure smooth operation, these cam followers are critical components in applications requiring precise linear or oscillating motion under challenging conditions.