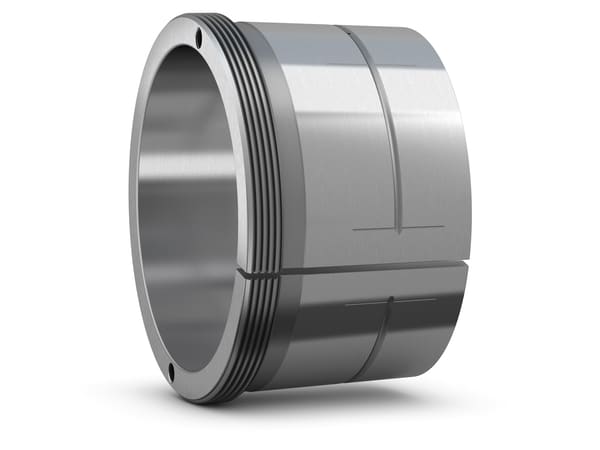

SKF withdrawal sleeves (taper sleeves) are precision-engineered bearing mounting components designed to facilitate secure fitting and removal of bearings with tapered bores onto cylindrical shafts. These mechanical aids enable efficient assembly/disassembly while maintaining optimal bearing alignment and preventing shaft damage, forming an essential part of industrial power transmission systems.

Technical Specifications

SKF lock nuts and locking devices are mainly used to fix bearings on shafts, ensuring stability and reliability. SKF offers lock nuts including KM 19 and KM 16 models, which have metric threads and four evenly distributed grooves to accommodate a wrench. They are prevented from accidentally loosening by locking washers and can be reused without damage.

SKF Adapter sleeves are commonly used components for locating bearings, especially for mounting tapered bore bearings on cylindrical seats. They can be used on plain or stepped shafts, and are easy to install without the need for additional positioning on the shaft. Application scenarios and installation methods Normal shaft: When used on plain shafts, the bearing can be installed at any position on the shaft because the adapter sleeves allow the bearing to move freely on the shaft. Stepped shaft: When used on stepped shafts, they are usually used in conjunction with L-shaped spacer rings to accurately locate the axial position of the bearing and facilitate the installation and removal of the bearing. Material and manufacturing standards SKF