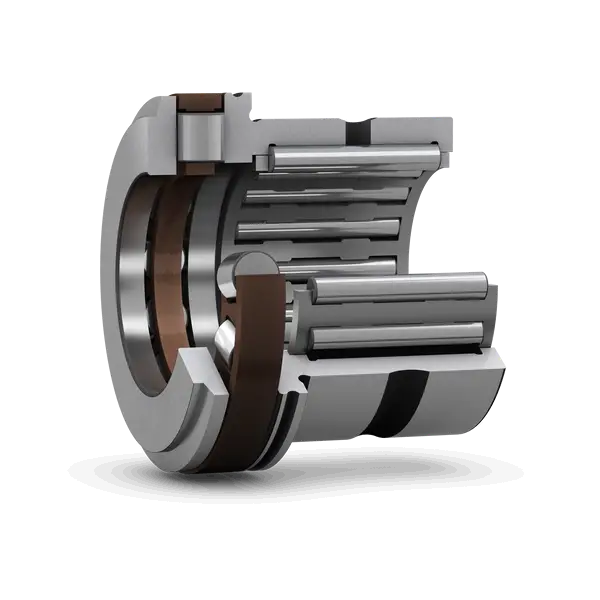

SKF Combined Needle Roller Bearings are a type of bearing that combines radial needle roller bearings and thrust bearings. They can withstand both radial and axial loads, and are particularly suitable for applications that require both loads, such as limited space or large axial loads. Structural Features Combined Needle Roller Bearings consist of the following parts: Radial Needle Roller Bearings: Mainly bear radial loads. Thrust Bearing Assembly: Includes outer ring, inner ring, preload device, etc., used to bear axial loads. The preload device can prevent the needle roller from sliding under light loads, thereby improving the performance of the bearing and extending its service life. Application Scenarios This bearing is particularly suitable for the following application scenarios: Limited Space: When other types of locating bearings take up too much space, Combined Needle Roller Bearings can be positioned in a smaller radial space. Large Axial Load: When the axial load is large and a simple thrust washer cannot bear it. Poor lubrication conditions: In the case of poor lubrication conditions, Combined Needle Roller Bearings can provide better lubrication effect.