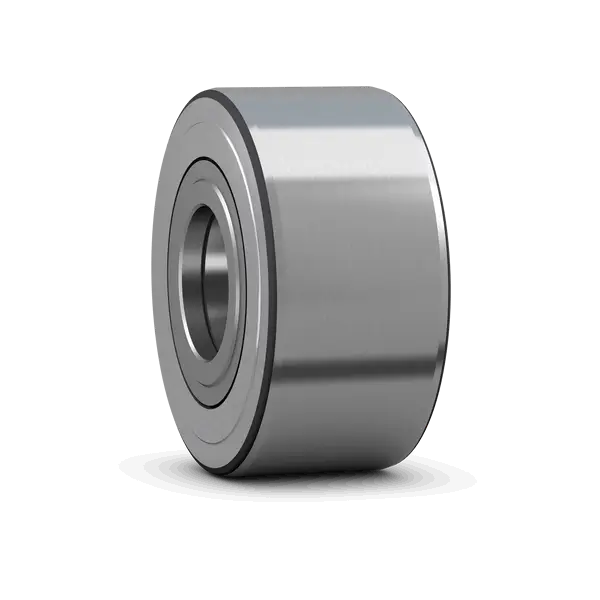

SKF cam rollers (yoke-type track rollers) are rolling bearings designed for various track operations and are commonly used in cam drives, conveyor systems, etc.

Designs and specifications SKF cam rollers are mainly available in two designs: Single-row cam rollers: Based on deep groove ball bearings, they belong to the 62 series. Double-row cam rollers: Based on double-row angular contact ball bearings, they belong to the 32 series. SKF also offers a variety of designs and variants with or without flange rings, with or without inner rings, with or without seals

Performance features Long life: Specially designed thrust washers improve the anti-seizure properties of the sliding surface. Maintenance-free: Labyrinth seals are used to ensure maintenance-free operation. Shock-resistant: The thick outer ring and

SKF Cam Followers (Stud-type track rollers) are bearings designed to run on various tracks and are commonly used in cam drives, conveyor systems, etc. They are based on needle roller bearings and have a threaded solid stud instead of an inner ring. This design enables Cam Followers to perform well in different working conditions, especially where high radial load capacity and axial loads caused by runout or tilt are required. Design and functional features The design of Cam Followers includes an eccentric sleeve pressed on the stud, as well as a thick-walled outer ring and crowned running surface. This design not only improves radial load capacity, but also withstands axial loads, extends service life, and is easy to install. In addition, the bearings are sealed on both sides for increased reliability and can be relubricated via the studs.

SKF Support rollers (Yoke-type track rollers) are rolling bearings designed for various tracks and are suitable for application scenarios such as cam drives and conveyor systems. They are based on needle roller bearings (fig. 1) or cylindrical roller bearings (fig. 2) and are available in a variety of designs and variants, including with or without cages, with or without flange rings, with or without inner rings, with or without seals, etc. Design and functional features The main features of SKF Support rollers include: High load capacity: These roller bearings are compact and can withstand high radial loads and can absorb axial loads caused by alignment errors or misalignment Wide applicability: Suitable for various types of tracks, including thick-walled outer ring design, capable of withstanding high radial loads Easy installation: Pre-assembled accessories are provided and can be installed directly without further adjustment Application scenarios SKF Support rollers are widely used in various industrial applications, including but not limited to: Conveyor systems: Provide stable support and drive in conveyor systems. Cam drives: Provide precise transmission and support in cam drive systems.