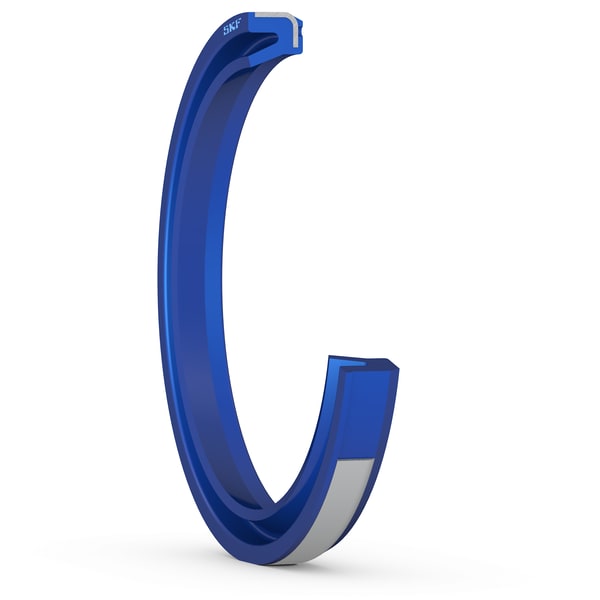

In hydraulic and pneumatic systems, contamination is one of the leading causes of premature component failure. Dirt, moisture, and debris can compromise system efficiency, increase wear, and lead to costly downtime. SKF hydraulic wiper seals are engineered to prevent these issues by effectively scraping away contaminants from piston rods, cylinders, and other moving components. Designed for durability, precision, and high performance, SKF wiper seals ensure optimal system reliability across a wide range of industrial, automotive, and precision equipment applications.

In demanding industrial and mobile hydraulic applications, sealing systems play a critical role in ensuring efficiency, longevity, and contamination control. SKF, a global leader in precision engineering, offers a comprehensive range of **hydraulic seals and piston seals** designed to meet the rigorous demands of heavy machinery, automotive systems, and precision hydraulic equipment. Combining advanced materials, innovative design, and decades of expertise, SKF seals deliver superior leak prevention, reduced friction, and extended service life—even under extreme pressures, temperatures, and dynamic operating conditions.

In hydraulic systems, maintaining optimal performance and reliability depends on the integrity of sealing solutions. SKF, a global leader in precision engineering, offers a comprehensive range of **hydraulic seals**, including specialized **rod seals** and **buffer seals**, designed to withstand extreme pressures, dynamic motion, and harsh operating conditions. These seals play a critical role in preventing fluid leakage, minimizing friction, and extending the service life of hydraulic cylinders and other industrial machinery.

In demanding industrial and mobile hydraulic applications, sealing systems play a critical role in ensuring efficiency, longevity, and contamination control. SKF, a global leader in bearing and sealing solutions, offers a comprehensive range of **hydraulic seals and guide rings** designed to withstand extreme pressures, dynamic movements, and harsh operating conditions. These precision-engineered components are essential for maintaining optimal performance in hydraulic cylinders, pumps, valves, and other fluid power systems across industries such as construction, agriculture, automotive, and manufacturing.