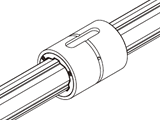

The THK Ball Spline Caged Ball Spline Model SLS (medium load type) SERIES represents a specialized linear motion component engineered for applications requiring precise torque transmission and linear guidance under moderate load conditions. This ball spline design incorporates a unique caged ball construction where precision steel balls are systematically arranged and retained within a cage structure between the spline shaft and the nut. This configuration ensures smooth, low-friction movement while maintaining accurate rotational and linear positioning, making it ideal for scenarios involving combined linear and rotary motions.

Key technical features of the SLS series include its robust medium-load capacity, achieved through optimized ball groove geometry and high-grade materials that provide excellent resistance to wear and deformation. The caged ball design minimizes friction and prevents ball-to-ball contact, reducing heat generation and extending operational life. The spline shaft is precision-ground to tight tolerances, ensuring minimal backlash and high rigidity. Additionally, the nut assembly is designed for easy integration with standard mounting configurations, and options for lubrication fittings facilitate maintenance in demanding environments. The series is available in various shaft diameters and lengths to accommodate diverse application requirements.

Performance advantages are evident in its ability to handle simultaneous linear and rotational forces with high efficiency and precision. The low friction coefficient results in smoother operation and reduced power consumption, while the high rigidity minimizes deflection under load, maintaining accuracy in dynamic conditions. The caged ball system enhances durability by distributing loads evenly across the balls, reducing stress concentrations and mitigating the risk of brinelling. This design also allows for higher speeds and accelerations compared to conventional splines, thanks to reduced vibration and noise levels. Furthermore, the SLS series operates reliably in contaminated environments when paired with appropriate seals, ensuring consistent performance in industrial settings.

Typical applications span multiple industries, leveraging the series' versatility. In industrial machinery, it is commonly used in automated assembly lines for robotic arm joints, where precise linear and rotary movements are critical for tasks like pick-and-place operations or welding. In automotive systems, the SLS series finds use in steering column mechanisms, transmission shifters, and throttle control linkages, providing reliable torque transmission and positioning accuracy. For precision equipment, it supports applications such as semiconductor manufacturing devices, medical imaging systems, and optical alignment tools, where minimal backlash and high repeatability are essential. Its medium-load capacity makes it suitable for scenarios that demand a balance between performance and compact design, such as packaging machinery or CNC tool changers, ensuring efficient and long-lasting operation in repetitive motion tasks.

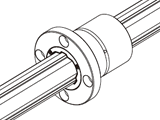

The THK Ball Spline Caged Ball Spline Model SLF (Medium Load Type) Series represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, rigidity, and durability under moderate to high load conditions. This series incorporates a unique caged ball design, where precision-ground balls are retained within a cage structure, effectively minimizing friction, reducing heat generation, and eliminating the need for complex lubrication systems. The spline shaft and nut assembly are manufactured from high-grade chromium steel, subjected to rigorous heat treatment processes to achieve superior surface hardness and core toughness, ensuring prolonged service life even in demanding operational environments.

Key technical features of the SLF Series include its ability to simultaneously accommodate torque and linear motion with minimal backlash, thanks to the optimized ball groove geometry and precise preloading. The caged ball mechanism prevents ball-to-ball contact, drastically reducing wear and operational noise, while facilitating smoother motion and higher speeds. Its compact, yet robust, design allows for easy integration into space-constrained applications without compromising on load capacity or performance stability. The series is available in various shaft diameters and standard lengths, offering flexibility for custom configurations and specific engineering requirements.

Performance advantages are evident in its high positional accuracy, repeatability, and resistance to moment loads, making it an ideal choice for applications requiring synchronized rotary and linear movements. The reduced maintenance needs, attributed to the efficient cage-guided ball recirculation, lower total cost of ownership by extending relubrication intervals and minimizing downtime. Enhanced corrosion resistance options further broaden its suitability for harsh environments, including those with exposure to coolants, chemicals, or extreme temperatures.

Typical applications span across multiple industries, leveraging the SLF Series' reliability and precision. In industrial machinery, it is commonly deployed in automated assembly lines, robotic arms, and material handling equipment where precise positioning and high load-bearing capabilities are critical. Within automotive systems, it finds use in steering mechanisms, transmission testing rigs, and brake system actuators, contributing to improved safety and performance. In the realm of precision equipment, the SLF Series is integral to semiconductor manufacturing devices, optical alignment systems, and medical diagnostic instruments, where minimal vibration and exact motion control are paramount. Its versatility and engineered excellence make it a cornerstone component for advancing automation and precision across diverse technological fields.

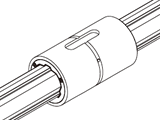

THK's Ball Spline Caged Ball Spline Model SLS L (Heavy Load Type) Series represents a significant advancement in linear motion technology, engineered specifically for applications demanding exceptional load capacity, rigidity, and precision under the most challenging operational conditions. This series incorporates a unique caged ball design, where precision-ground balls are retained and guided by a robust cage structure within the spline shaft and nut assembly. This configuration eliminates ball-to-ball contact, drastically reducing friction, heat generation, and torque variation, while simultaneously enabling higher speeds and smoother motion compared to conventional ball splines. The SLS L series is characterized by its large-diameter shaft and optimized ball circulation path, which are fundamental to its heavy-load nomenclature, providing superior resistance to moment loads and offering a significantly higher static and dynamic load rating.

Key technical features that define the SLS L series include its high rigidity, which minimizes elastic deformation under load for unparalleled positional accuracy. The caged ball design ensures consistent, reliable lubrication retention and dramatically lowers the required torque for movement, contributing to enhanced energy efficiency and reduced wear over the system's lifespan. Furthermore, the design allows for precise preloading adjustments, enabling engineers to fine-tune the assembly to eliminate backlash and achieve zero clearance for applications requiring the highest levels of repeatability. The components are manufactured from high-grade chromium steel, subjected to rigorous heat treatment processes to ensure exceptional surface hardness and core toughness, resulting in an extended service life even in environments with significant shock and vibration.

The performance advantages of the SLS L series translate directly into operational benefits across a diverse range of demanding sectors. In industrial machinery, these ball splines are indispensable in heavy-duty automation, such as the vertical axes of large machining centers, heavy-duty transfer lines, and precision assembly robots where high moment loads are prevalent. The automotive industry leverages their robustness in welding gun manipulators, heavy-duty material handling systems, and precision testing equipment for powertrain components. Within the realm of precision equipment, the SLS L series finds critical application in semiconductor manufacturing apparatus, large-format precision measuring machines, and advanced optical alignment systems, where its ability to maintain accuracy under substantial load is paramount. By delivering a combination of massive load capacity, exceptional rigidity, and smooth, low-friction motion, the THK SLS L Series provides a foundational component for engineers designing the next generation of high-performance, reliable industrial systems.