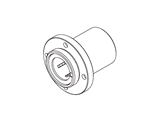

The THK LMIF/L Series flanged-type linear bushings represent a high-performance circular flange design within the THK Guide Ball Bushing range, engineered to provide exceptional linear motion support for shafts. This model is characterized by its integrated circular flange, which facilitates straightforward and secure mounting to machine frames or moving elements, eliminating the need for additional complex mounting brackets or blocks. The construction utilizes a precision-formed steel shell, housing a retainer that accurately spaces and guides a full complement of high-grade steel balls. These balls recirculate smoothly along the shaft with minimal friction, enabling precise linear travel.

Key technical features of the LMIF/L Series include its compact flanged design, which saves space and simplifies assembly in constrained layouts. The bushings are manufactured to tight tolerances, ensuring high running accuracy and repeatability. They incorporate THK's advanced ball groove form, which optimizes contact with the shaft to provide high rigidity and load capacity. A robust seal or shield system is typically integrated to protect the internal ball recirculation elements from contaminants like dust, chips, and moisture, thereby maintaining performance and extending service life in demanding environments. The design also allows for smooth, low-friction motion, which is critical for applications requiring high positional accuracy.

Performance advantages are substantial, starting with the ability to handle significant radial loads, making them suitable for applications where the guiding element must support the weight and forces of the moving component. The low coefficient of friction inherent in the ball recirculating design translates to high efficiency, requiring less drive force and enabling higher speeds with minimal heat generation. This contributes to energy savings and reduced wear. The flanged configuration provides excellent resistance to moment loads, enhancing stability and preventing tilting or misalignment during operation. Their durability and long service life, even under continuous or high-cycle duty, reduce maintenance frequency and total cost of ownership.

Typical applications for the THK LMIF/L Series flanged linear bushings are widespread across industries demanding reliable linear guidance. In industrial machinery, they are commonly found in the linear axes of automated assembly systems, packaging equipment, material handling conveyors, and the sliding tables of machine tools, where they ensure precise and smooth movement. Within automotive manufacturing and testing systems, these components are utilized in positioning fixtures, robotic arm end-effectors, and parts transfer mechanisms that require robust performance under high loads and repetitive cycles. For precision equipment, such as semiconductor manufacturing apparatus, medical diagnostic devices, and optical positioning stages, the LMIF/L Series provides the critical accuracy, smooth motion, and cleanliness necessary for sensitive processes. Their versatility and reliability make them a fundamental component in advancing automation and precision across modern industrial and technological sectors.

The THK LMIF SERIES flanged type linear bushings represent a high-performance circular flange design within the Guide Ball Bushing Linear Bushing family, engineered for robust and precise linear motion. These components feature a compact, integral flange that facilitates straightforward and secure mounting onto machine frames or moving elements, eliminating the need for additional complex housing units. The fundamental construction incorporates a precision-engineered outer sleeve, a retainer that effectively manages the recirculation of balls, and a complement of high-grade steel balls that provide the rolling contact between the shaft and the bushing. This design ensures smooth, low-friction travel along a supported shaft.

Key technical features define the LMIF SERIES's operational superiority. The flanged configuration offers significant design convenience, providing a stable bolting surface that resists rotation and simplifies alignment during assembly. Internally, the optimized recirculation system for the balls minimizes vibration and noise while maintaining consistent contact, which is critical for high-speed applications. The bushings are manufactured to tight tolerances, ensuring high running accuracy and repeatability of positioning. Many models within this series are available with sealing options, such as rubber or metal seals, to effectively exclude contaminants like dust and chips while retaining essential lubricants, thereby enhancing service life in demanding environments. The materials used, including high-carbon chromium bearing steel for critical components, are selected for their durability, wear resistance, and ability to handle substantial static and dynamic loads.

The performance advantages of the LMIF flanged bushings translate directly into enhanced machine capability. Their low coefficient of friction contributes to higher mechanical efficiency, allowing for the use of smaller, more economical drive motors and reducing overall energy consumption. The high rigidity of the unit supports heavy loads with minimal deformation, ensuring precision is maintained even under significant stress. This combination of smooth motion, high load capacity, and excellent durability results in a long operational lifespan with minimal maintenance requirements, reducing total cost of ownership. Their ability to perform reliably at high speeds makes them suitable for modern automated processes.

Typical applications for the THK LMIF SERIES are found across a wide spectrum of industries demanding reliability and precision. In industrial machinery, they are integral to the linear axes of automated assembly robots, pick-and-place units, material handling systems, and the sliding tables of machining centers. Within the automotive sector, these bushings are employed in precision testing equipment, robotic welding arms, and automated assembly lines for engines and transmissions. For precision equipment, the LMIF SERIES is often specified in the critical motion stages of semiconductor manufacturing apparatus, optical positioning systems, and medical diagnostic devices where smooth, accurate, and contamination-free motion is paramount. Their versatile flanged design makes them a preferred solution for simplifying construction and improving the performance of linear motion systems where space is at a premium and reliability is non-negotiable.