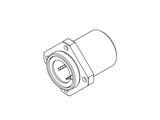

The THK LMIK L SERIES flanged type Square Flange Linear Bushing represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, rigidity, and longevity in demanding industrial applications. This ball bushing linear bushing is characterized by its compact square flange design, which facilitates straightforward and secure mounting onto machine frames, worktables, and automated assemblies. The flange incorporates multiple precision-machined mounting holes, ensuring stable fixation and accurate alignment, which is critical for maintaining system integrity under high loads and dynamic conditions.

Technically, the LMIK L SERIES incorporates a meticulously designed ball recirculation system within its outer sleeve, manufactured from high-carbon chromium bearing steel (SUJ2) for superior wear resistance and durability. The balls are precision-ground to micron-level tolerances, enabling smooth, low-friction travel along compatible shafts. An integral sealing system, often comprising contact or non-contact seals, is incorporated to effectively exclude contaminants such as dust, chips, and moisture while retaining essential lubrication. This design significantly reduces maintenance intervals and prevents premature failure. The bushing's internal structure ensures even load distribution across all balls, minimizing stress concentrations and enabling high load capacities—both radial and moment loads—without compromising performance.

Performance advantages are substantial and multifaceted. The rigid square flange design provides excellent resistance to torque and tilting moments, enhancing the overall stability of the linear motion system. This results in improved positional accuracy and repeatability, which is paramount for precision tasks. The low coefficient of friction inherent in the ball-to-track interface allows for high-speed operation with minimal heat generation, contributing to energy efficiency and consistent performance over extended periods. Furthermore, the optimized recirculation geometry minimizes noise and vibration, leading to quieter machine operation—a critical benefit in noise-sensitive environments like automotive test facilities or medical device manufacturing.

Typical applications for the THK LMIK L SERIES are diverse, spanning numerous high-performance sectors. In industrial machinery, these bushings are integral to CNC machining centers, where they guide tool carriers and worktables with high precision and rigidity, directly impacting machining accuracy and surface finish quality. Within automotive manufacturing systems, they are employed in robotic welding arms, automated assembly pallets, and precision testing equipment, where reliability under high cyclic loads and environmental contaminants is non-negotiable. For precision equipment, the series finds use in semiconductor fabrication tools, optical positioning stages, and medical diagnostic devices, where smooth, precise, and backlash-free motion is essential for achieving micron-level accuracies. The robust construction and high-performance characteristics make the LMIK L SERIES a preferred component for engineers designing systems that demand reliability, precision, and long-term operational consistency.

The THK LMIK Series flanged type Square Flange Model LMIK Linear Bushing represents a high-performance, compact ball bushing solution engineered for precision linear motion in demanding industrial environments. This flanged design incorporates a square-shaped flange that provides robust mounting stability and simplifies installation in space-constrained applications. The unit features a precision-engineered outer sleeve and flange manufactured from high-carbon chromium bearing steel, hardened to optimal levels to ensure exceptional wear resistance and long-term dimensional stability. Inside, precision-ground raceways and a meticulously designed ball recirculation system facilitate smooth, low-friction travel with minimal rolling resistance.

Key technical features include the incorporation of high-grade steel balls that are precisely sized and finished to minimize vibration and noise during operation. The ball recirculation system is optimized to provide consistent, uninterrupted motion, even at high speeds, while the compact flange design allows for direct mounting to machine frames or moving components without additional bracketing. The LMIK Series is available in various standard sizes and can be supplied with optional seals or shields to protect the internal ball tracks from contaminants such as dust, chips, or moisture, significantly extending service life in harsh environments.

Performance advantages of the LMIK Series are substantial, offering high rigidity and load capacity relative to its compact size. The square flange distributes mounting forces evenly, reducing stress concentrations and enhancing alignment accuracy. This results in improved positional repeatability and reduced deflection under load, which is critical for applications requiring precise linear guidance. The low-friction characteristics contribute to higher efficiency, reducing the power required for actuation and enabling smoother acceleration and deceleration profiles. Additionally, the hardened components and efficient sealing options ensure extended maintenance intervals and reliable operation over long periods, even under continuous or high-cycle duty.

Typical applications for the THK LMIK Linear Bushing are found across multiple sectors, including industrial automation where it guides slides in pick-and-place units, assembly robots, and linear actuators. In automotive manufacturing systems, it is employed in precision jigs, welding equipment, and automated testing machinery that demand reliable, low-maintenance linear motion. Within precision equipment, the LMIK Series is utilized in optical positioning stages, medical device actuators, and semiconductor handling systems where smooth, accurate motion and contamination resistance are paramount. Its versatility and durability make it suitable for both vertical and horizontal orientations, supporting a wide range of loads and speeds while maintaining consistent performance in diverse operating conditions.