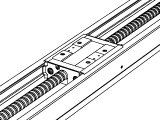

THK's LM Guide Actuator SKR20 Series represents a sophisticated evolution in linear motion technology, integrating the precision of a Caged Ball LM Guide with a robust actuator mechanism. This system features a long nut block design, available in variants A and B, both equipped with protective covers to ensure durability and consistent performance in demanding environments. The core innovation lies in its caged ball retainer system, which encapsulates each ball within a precise cage structure. This design eliminates metal-to-metal contact between balls, drastically reducing friction, heat generation, and wear. The SKR20's construction ensures smooth, quiet operation with minimal vibration, even at high speeds or under substantial loads.

Key technical features include the high-rigidity, long nut block that provides enhanced stability and load capacity. The integrated cover effectively shields critical components from contaminants such as dust, chips, and moisture, significantly extending service life and reducing maintenance requirements. The actuator is engineered for high positional accuracy and repeatability, making it suitable for applications demanding precise linear positioning. Its compact design allows for efficient use of space within machinery layouts, while the pre-loaded ball screw mechanism minimizes backlash, ensuring responsive and accurate motion control.

Performance advantages are substantial across various metrics. The caged ball system not only lowers friction for higher efficiency but also allows for greater maximum speeds and accelerations compared to conventional designs. This results in improved cycle times and throughput in automated systems. The longevity of the SKR20 is notably extended due to reduced wear on rolling elements and raceways, translating to lower total cost of ownership. Its ability to maintain precision under heavy loads and high moment forces makes it exceptionally reliable for rigorous industrial duties.

Typical applications for the THK LM Guide Actuator SKR20 Series are found in sectors where precision, reliability, and durability are paramount. In industrial automation, it is deployed in CNC machining centers for tool changing mechanisms, precision assembly robots for electronic component placement, and automated material handling systems for precise positioning of grippers and actuators. Within the automotive industry, it serves in welding robot arms, precision testing equipment for quality control, and automated assembly lines for engine and transmission components. In the realm of precision equipment, the SKR20 is ideal for semiconductor manufacturing apparatus, medical device automation such as DNA analyzers or surgical robots, and optical alignment systems where smooth, accurate linear motion is critical to operational success.

THK's LM Guide Actuator Caged Ball LM Guide Actuator SKR20 with Long Nut Block A/B SERIES represents a sophisticated integration of linear motion technology designed for high-precision, high-load applications. This system combines a precision-ground LM guide with a ball screw actuator, featuring a unique caged ball design that enhances performance and longevity. The SKR20 model, in particular, is engineered with a compact profile while maintaining robust load capacity, making it suitable for space-constrained industrial environments. The long nut block, available in A and B series variants, provides extended contact with the ball screw, distributing loads evenly and reducing wear for sustained accuracy over time.

Key technical features include the caged ball mechanism, which separates and retains balls within the LM guide and actuator to minimize friction, noise, and heat generation. This design prevents ball-to-ball contact, reducing operational vibration and allowing for smoother, more consistent motion. The LM guide incorporates precision-racedway grooves and high-grade steel construction, ensuring minimal deflection under heavy loads. The ball screw actuator boasts high lead accuracy and efficiency, with preloaded nuts to eliminate backlash and enhance positional repeatability. Additionally, the long nut block variants offer optimized preload settings—Series A for moderate loads and Series B for higher rigidity and load capacity—enabling customization based on application demands. Sealing systems are integrated to protect against contaminants like dust and moisture, extending service life in harsh conditions.

Performance advantages of this actuator system are substantial, starting with its ability to handle combined loads—radial, reverse radial, and moment loads—with high stiffness and stability. The caged ball design contributes to a longer maintenance interval by reducing lubricant depletion and wear, while the low friction coefficient allows for higher speeds and accelerations without sacrificing precision. Energy efficiency is improved due to reduced power requirements for motion initiation and maintenance. In terms of durability, the hardened steel components and corrosion-resistant treatments ensure reliable operation in demanding environments, with noise levels kept low for operator comfort and compliance with industrial standards.

Typical applications span across industrial machinery, automotive systems, and precision equipment. In industrial automation, it is commonly used in CNC machining centers for tool positioning, robotic arm articulation, and pick-and-place systems where high accuracy and repeatability are critical. The automotive industry employs these actuators in assembly lines for precise component handling, welding robots, and testing equipment that requires robust performance under cyclic loads. For precision equipment, such as semiconductor manufacturing tools, medical devices, and optical alignment systems, the SKR20 actuator provides the sub-micron level accuracy necessary for sensitive operations. Its versatility also extends to packaging machinery, where smooth linear motion ensures efficient product handling and labeling processes. By delivering a blend of precision, durability, and adaptability, THK's LM Guide Actuator SKR20 with Long Nut Block A/B SERIES supports enhanced productivity and reliability in advanced mechanical systems.