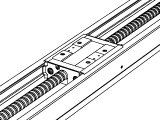

The THK LM Guide Actuator SKR26 Series represents a sophisticated evolution in linear motion technology, integrating the precision of a Caged Ball LM Guide with the robust functionality of an actuator system. This series features a long nut block design, available in variations A and B, both equipped with protective covers to ensure longevity and consistent performance in demanding environments. The core innovation lies in its caged ball retainer system, which meticulously separates each rolling element within the guide to eliminate metal-on-metal contact, drastically reducing friction, heat generation, and wear. This design not only enhances operational smoothness but also allows for significantly higher speeds and accelerations compared to conventional ball screw actuators.

Key technical features include the SKR26’s high rigidity and exceptional load capacity, distributed evenly across radial, reverse radial, and lateral directions, thanks to its optimized ball groove geometry and precise preloading. The long nut block extends the engagement length with the screw shaft, maximizing contact area to support higher torque transmission and minimize deflection under heavy loads. The integrated cover on blocks A and B acts as a critical barrier against contaminants such as dust, chips, and moisture, making it ideal for unclean or washdown environments. Additionally, the actuator delivers high positioning accuracy and repeatability, with low noise levels and minimal maintenance requirements due to its efficient lubrication retention and reduced particle generation from the caged ball design.

Performance advantages are substantial across multiple metrics. The reduction in friction translates directly into lower energy consumption and extended service life, even under continuous duty cycles. Its ability to maintain precision at high speeds makes it suitable for dynamic applications where both speed and accuracy are paramount. The sealed design enhances reliability in harsh conditions, reducing downtime and maintenance intervals. Furthermore, the caged ball system prevents torque fluctuation and stick-slip motion, ensuring smooth starts and stops critical in precision automation.

Typical applications span a diverse range of industries. In industrial machinery, the SKR26 Series is deployed in high-speed CNC machining centers for tool changers and axis drives, automated assembly lines for precise part positioning, and packaging machinery requiring rapid, repeatable movements. Within automotive manufacturing, it serves in robotic welding arms, precision testing equipment, and powertrain assembly systems where durability and accuracy under load are essential. For precision equipment, this actuator is found in semiconductor fabrication tools, optical positioning stages, and medical device automation, where contamination control and sub-millimeter accuracy are critical. Its versatility and reliability make it a cornerstone component for enhancing productivity and precision in modern automated systems.

THK's LM Guide Actuator Caged Ball LM Guide Actuator SKR26 with Long Nut Block A/B SERIES represents a significant advancement in linear motion technology, engineered to deliver exceptional precision, rigidity, and durability in demanding industrial environments. This system integrates a recirculating ball mechanism within a caged structure, ensuring smooth, low-friction linear travel with minimal maintenance requirements. The SKR26 model features a compact design with a 26mm rail width, optimized for applications where space constraints and high load capacities are critical. The inclusion of the Long Nut Block in A or B SERIES configurations enhances mounting flexibility and load distribution, allowing for secure integration into various machinery setups.

Key technical features include the caged ball design, which prevents ball-to-ball contact and reduces wear, noise, and vibration. This results in a longer service life and consistent performance under high-speed and high-load conditions. The LM Guide Actuator incorporates precision-ground raceways and balls, achieving high accuracy with minimal deflection. The Long Nut Block is designed for easy installation and adjustment, featuring tapped holes and standardized dimensions that simplify alignment and reduce assembly time. Additionally, the system is pre-lubricated and sealed to resist contaminants like dust and moisture, making it suitable for harsh environments without frequent re-lubrication.

Performance advantages of the SKR26 series are evident in its ability to handle combined loads—including radial, reverse radial, and lateral forces—with high stiffness and positional accuracy. This makes it ideal for applications requiring repeatable linear motion, such as in CNC machining centers, where it ensures precise tool positioning and reduced cycle times. In automotive systems, the actuator is used in robotic welding arms and assembly lines, providing reliable movement for components like engine parts or chassis fixtures. Its low friction coefficient contributes to energy efficiency, reducing operational costs over time. For precision equipment, such as semiconductor manufacturing or medical devices, the SKR26's smooth operation minimizes vibration, critical for maintaining product quality in processes like wafer handling or diagnostic instrument positioning.

Typical applications span across industrial machinery, where it supports linear slides in packaging equipment and material handling systems, enabling fast, accurate product transfer. In automotive automation, it facilitates precise control in brake testing rigs or powertrain assembly, enhancing productivity and safety. The actuator's robustness also suits it for use in precision inspection machines, where stability and accuracy are paramount for measuring components in quality assurance processes. Overall, THK's SKR26 LM Guide Actuator with Long Nut Block A/B SERIES offers a reliable solution for industries prioritizing efficiency, longevity, and precision in linear motion systems.