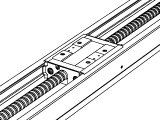

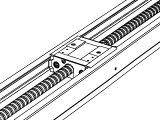

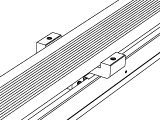

The THK LM Guide Actuator, specifically the Caged Ball LM Guide Actuator SKR33 with Long Nut Block A, represents a sophisticated integration of linear motion technology designed for high precision, durability, and efficiency in demanding applications. This system combines a recirculating ball-based LM guide with an actuator mechanism, featuring a unique caged ball design that separates and encloses the rolling elements within a retainer. This prevents ball-to-ball contact, reducing friction, heat generation, and wear, while ensuring smooth, consistent motion even at high speeds or under varying loads. The SKR33 model, with its standardized dimensions and robust construction, is engineered for long travel lengths and high load capacities, making it suitable for industrial environments where reliability is paramount.

Key technical features include the caged ball structure, which minimizes noise and vibration, enhancing operational stability. The long nut block A provides extended contact with the screw shaft, distributing loads evenly and improving rigidity for precise positioning. Preloaded ball grooves in the guide rails eliminate backlash, ensuring repeatable accuracy within microns. Additionally, the actuator incorporates seals and wipers to protect against contaminants like dust and debris, extending service life in harsh conditions. Materials such as hardened steel for rolling elements and corrosion-resistant coatings contribute to its longevity, while optional lubrication systems maintain optimal performance with minimal maintenance.

Performance advantages of this LM guide actuator are substantial. It offers high positional accuracy and smooth motion, critical for applications requiring precise linear movement. The caged ball design reduces torque variation and energy consumption, leading to improved efficiency and lower operational costs. With a high load-carrying capacity, it can handle combined radial, reverse radial, and moment loads, making it versatile for complex machinery. Its durability translates to reduced downtime and maintenance intervals, while the compact design saves space in automated systems. In high-speed operations, it maintains stability without sacrificing precision, a key benefit in industries like semiconductor manufacturing or robotics.

Typical applications span across industrial machinery, automotive systems, and precision equipment. In industrial automation, it is used in CNC machines, pick-and-place robots, and assembly lines for accurate part handling and positioning. Automotive manufacturers employ it in welding robots, engine assembly systems, and testing equipment where repeatability and speed are essential. For precision instruments, such as medical devices, optical alignment systems, or measuring apparatus, the actuator's low friction and high accuracy ensure reliable performance. Overall, the THK LM Guide Actuator SKR33 with Long Nut Block A is a reliable solution for enhancing productivity and precision in modern engineering applications.

The THK LM Guide Actuator, specifically the Caged Ball LM Guide Actuator SKR33 with Long Nut Block A, represents a sophisticated integration of linear motion technology designed for high precision, durability, and efficiency in demanding applications. This system combines a recirculating ball-based LM guide with an actuator mechanism, featuring a unique caged ball design that separates and encloses the rolling elements within a retainer. This prevents ball-to-ball contact, reducing friction, heat generation, and wear, while ensuring smooth, consistent motion even at high speeds or under varying loads. The SKR33 model, with its standardized dimensions and robust construction, is engineered for long travel lengths and high load capacities, making it suitable for industrial environments where reliability is paramount.

Key technical features include the caged ball structure, which minimizes noise and vibration, enhancing operational stability. The long nut block A provides extended contact with the screw shaft, distributing loads evenly and improving rigidity for precise positioning. Preloaded ball grooves in the guide rails eliminate backlash, ensuring repeatable accuracy within microns. Additionally, the actuator incorporates seals and wipers to protect against contaminants like dust and debris, extending service life in harsh conditions. Materials such as hardened steel for rolling elements and corrosion-resistant coatings contribute to its longevity, while optional lubrication systems maintain optimal performance with minimal maintenance.

Performance advantages of this LM guide actuator are substantial. It offers high positional accuracy and smooth motion, critical for applications requiring precise linear movement. The caged ball design reduces torque variation and energy consumption, leading to improved efficiency and lower operational costs. With a high load-carrying capacity, it can handle combined radial, reverse radial, and moment loads, making it versatile for complex machinery. Its durability translates to reduced downtime and maintenance intervals, while the compact design saves space in automated systems. In high-speed operations, it maintains stability without sacrificing precision, a key benefit in industries like semiconductor manufacturing or robotics.

Typical applications span across industrial machinery, automotive systems, and precision equipment. In industrial automation, it is used in CNC machines, pick-and-place robots, and assembly lines for accurate part handling and positioning. Automotive manufacturers employ it in welding robots, engine assembly systems, and testing equipment where repeatability and speed are essential. For precision instruments, such as medical devices, optical alignment systems, or measuring apparatus, the actuator's low friction and high accuracy ensure reliable performance. Overall, the THK LM Guide Actuator SKR33 with Long Nut Block A is a reliable solution for enhancing productivity and precision in modern engineering applications.

The THK LM Guide Actuator, specifically the Caged Ball LM Guide Actuator SKR33 with Long Nut Block A, represents a sophisticated integration of linear motion technology designed for high precision, durability, and efficiency in demanding applications. This system combines a recirculating ball-based LM guide with an actuator mechanism, featuring a unique caged ball design that separates and encloses the rolling elements within a retainer. This prevents ball-to-ball contact, reducing friction, heat generation, and wear, while ensuring smooth, consistent motion even at high speeds or under varying loads. The SKR33 model, with its standardized dimensions and robust construction, is engineered for long travel lengths and high load capacities, making it suitable for industrial environments where reliability is paramount.

Key technical features include the caged ball structure, which minimizes noise and vibration, enhancing operational stability. The long nut block A provides extended contact with the screw shaft, distributing loads evenly and improving rigidity for precise positioning. Preloaded ball grooves in the guide rails eliminate backlash, ensuring repeatable accuracy within microns. Additionally, the actuator incorporates seals and wipers to protect against contaminants like dust and debris, extending service life in harsh conditions. Materials such as hardened steel for rolling elements and corrosion-resistant coatings contribute to its longevity, while optional lubrication systems maintain optimal performance with minimal maintenance.

Performance advantages of this LM guide actuator are substantial. It offers high positional accuracy and smooth motion, critical for applications requiring precise linear movement. The caged ball design reduces torque variation and energy consumption, leading to improved efficiency and lower operational costs. With a high load-carrying capacity, it can handle combined radial, reverse radial, and moment loads, making it versatile for complex machinery. Its durability translates to reduced downtime and maintenance intervals, while the compact design saves space in automated systems. In high-speed operations, it maintains stability without sacrificing precision, a key benefit in industries like semiconductor manufacturing or robotics.

Typical applications span across industrial machinery, automotive systems, and precision equipment. In industrial automation, it is used in CNC machines, pick-and-place robots, and assembly lines for accurate part handling and positioning. Automotive manufacturers employ it in welding robots, engine assembly systems, and testing equipment where repeatability and speed are essential. For precision instruments, such as medical devices, optical alignment systems, or measuring apparatus, the actuator's low friction and high accuracy ensure reliable performance. Overall, the THK LM Guide Actuator SKR33 with Long Nut Block A is a reliable solution for enhancing productivity and precision in modern engineering applications.

The THK LM Guide Actuator, specifically the Caged Ball LM Guide Actuator SKR33 with Long Nut Block A, represents a sophisticated integration of linear motion technology designed for high precision, durability, and efficiency in demanding applications. This system combines a recirculating ball-based LM guide with an actuator mechanism, featuring a unique caged ball design that separates and encloses the rolling elements within a retainer. This prevents ball-to-ball contact, reducing friction, heat generation, and wear, while ensuring smooth, consistent motion even at high speeds or under varying loads. The SKR33 model, with its standardized dimensions and robust construction, is engineered for long travel lengths and high load capacities, making it suitable for industrial environments where reliability is paramount.

Key technical features include the caged ball structure, which minimizes noise and vibration, enhancing operational stability. The long nut block A provides extended contact with the screw shaft, distributing loads evenly and improving rigidity for precise positioning. Preloaded ball grooves in the guide rails eliminate backlash, ensuring repeatable accuracy within microns. Additionally, the actuator incorporates seals and wipers to protect against contaminants like dust and debris, extending service life in harsh conditions. Materials such as hardened steel for rolling elements and corrosion-resistant coatings contribute to its longevity, while optional lubrication systems maintain optimal performance with minimal maintenance.

Performance advantages of this LM guide actuator are substantial. It offers high positional accuracy and smooth motion, critical for applications requiring precise linear movement. The caged ball design reduces torque variation and energy consumption, leading to improved efficiency and lower operational costs. With a high load-carrying capacity, it can handle combined radial, reverse radial, and moment loads, making it versatile for complex machinery. Its durability translates to reduced downtime and maintenance intervals, while the compact design saves space in automated systems. In high-speed operations, it maintains stability without sacrificing precision, a key benefit in industries like semiconductor manufacturing or robotics.

Typical applications span across industrial machinery, automotive systems, and precision equipment. In industrial automation, it is used in CNC machines, pick-and-place robots, and assembly lines for accurate part handling and positioning. Automotive manufacturers employ it in welding robots, engine assembly systems, and testing equipment where repeatability and speed are essential. For precision instruments, such as medical devices, optical alignment systems, or measuring apparatus, the actuator's low friction and high accuracy ensure reliable performance. Overall, the THK LM Guide Actuator SKR33 with Long Nut Block A is a reliable solution for enhancing productivity and precision in modern engineering applications.