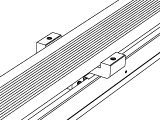

THK's LM Guide Actuator SKR33 series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with the compact efficiency of a motor wrap and short nut block design. This actuator is engineered for applications demanding high rigidity, smooth motion, and minimal maintenance. The Caged Ball LM Guide employs a unique caged ball retainer system that prevents ball-to-ball contact, reducing friction, heat generation, and wear, while ensuring consistent lubrication and quiet operation. The SKR33 model features a short nut block (Block C or D variants) with a cover, which minimizes the overall length and enhances resistance to contaminants like dust and chips. This design is paired with a motor wrap that simplifies installation and optimizes space utilization in tight layouts.

Key technical features include high load capacity, achieved through the optimized ball circulation path and rigid housing, allowing for both radial and lateral forces to be managed effectively. The actuator offers exceptional positioning accuracy and repeatability, with preload adjustments available to eliminate backlash and adapt to varying operational demands. Its sealed structure, including the cover on the nut block, provides IP65-equivalent protection, making it suitable for harsh environments. Performance advantages are evident in its ability to sustain high speeds and accelerations without sacrificing precision, thanks to reduced friction and efficient heat dissipation. The caged ball design extends service life by minimizing wear and maintaining lubricant integrity, which translates to lower long-term maintenance costs and reduced downtime.

In industrial machinery, the SKR33 actuator is ideal for automated assembly lines, CNC machine tool axes, and robotic handling systems where precision and durability are critical. Its compact motor wrap and short nut block enable seamless integration into multi-axis configurations, such as Cartesian robots or gantry systems, enhancing throughput and reliability. In automotive systems, it finds use in welding robots, part transfer mechanisms, and testing equipment, where high cycle rates and resistance to vibration are essential. For precision equipment, including semiconductor manufacturing devices, medical diagnostic instruments, or optical alignment systems, the actuator's low noise, smooth motion, and accuracy ensure consistent performance in sensitive applications. Overall, the THK LM Guide Actuator SKR33 series delivers a robust, space-saving solution that boosts efficiency and reliability across diverse industrial sectors.

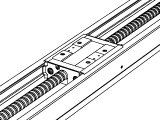

The THK LM Guide Actuator SKR33 series represents a sophisticated integration of linear motion technology, combining a Caged Ball LM Guide Actuator with a motor wrap, long nut, and block assemblies (Types A and B with cover). This design encapsulates a complete linear drive system where the caged ball mechanism ensures smooth, precise movement along the guide, while the actuator components convert rotary motion from the motor into controlled linear travel. The series is engineered for high-load capacity and exceptional rigidity, featuring a compact profile that minimizes space requirements in machinery layouts. Key technical attributes include the use of caged balls to reduce friction and prevent slippage, enhancing operational smoothness and longevity. The long nut design provides extended contact with the screw, distributing loads evenly and improving positioning accuracy. Blocks A and B, available with protective covers, offer flexibility in mounting and environmental sealing, safeguarding against contaminants like dust and moisture.

Performance advantages of the SKR33 series are substantial, delivering high precision with repeatability tolerances as tight as micrometers, making it ideal for applications demanding exact linear positioning. Its high-speed capability, coupled with low noise and vibration, ensures efficient operation in dynamic environments. The caged ball system minimizes heat generation and maintenance needs by reducing metal-to-metal contact, leading to extended service life and reliability even under continuous use. Additionally, the actuator's design allows for easy integration with various motor types, facilitating customization for specific torque and speed requirements. This results in energy efficiency and reduced operational costs, as the system requires less power to achieve desired motions compared to conventional linear guides.

In industrial machinery, the SKR33 series excels in automation equipment such as CNC machining centers, where it provides precise table movements for milling and drilling operations, enhancing product quality and throughput. It is also widely used in robotic arms and pick-and-place systems, enabling rapid, accurate part handling in assembly lines. Within automotive systems, this actuator supports critical processes like welding and painting robots, where its durability and precision ensure consistent joint quality and finish. In precision equipment, it finds applications in semiconductor manufacturing devices, including wafer steppers and inspection machines, where sub-micron accuracy is essential for circuit patterning and quality control. Medical devices, such as MRI scanners and automated diagnostic instruments, benefit from its smooth, quiet operation and reliability, ensuring patient safety and diagnostic accuracy. Overall, the THK LM Guide Actuator SKR33 series is a versatile solution for advancing productivity and precision across diverse high-tech industries.

THK's LM Guide Actuator series represents a sophisticated integration of linear motion technology, combining the precision of LM Guides with the driven functionality of an actuator in a compact, high-performance package. The Caged Ball LM Guide Actuator, specifically models like the SKR33 with motor wrap, short nut, and Block C/D SERIES configurations, is engineered for applications demanding exceptional accuracy, rigidity, and longevity. This system features a unique caged ball design where balls are retained in a cage within the ball circuit, minimizing friction and wear by preventing direct ball-to-ball contact. This design reduces heat generation and ensures smooth, consistent motion even at high speeds or under varying loads. The SKR33 model incorporates a motor wrap for direct motor integration, simplifying assembly and enhancing positional accuracy by minimizing backlash. The short nut design contributes to a more compact overall footprint, making it ideal for space-constrained environments without sacrificing load capacity or stroke length. Block C and D SERIES refer to specific housing designs that optimize mounting flexibility and structural support, with variations in dimensions, preload levels, and sealing options to suit diverse operational conditions.

Key technical features include high rigidity achieved through optimized contact angles between the balls and raceways, which distribute loads evenly and resist deformation under moment forces. The actuator delivers precise linear positioning with repeatability in the micrometer range, supported by preloaded ball screws that eliminate axial play. Performance advantages are substantial: the caged ball system extends service life by reducing lubricant consumption and preventing debris ingress, while the compact motor wrap integration reduces system complexity and maintenance needs. It operates efficiently at speeds up to 5 m/s with accelerations exceeding 30 m/s², making it suitable for dynamic applications. Noise levels are minimized due to the controlled ball movement, enhancing workplace safety and comfort.

Typical applications span industrial machinery, where these actuators drive CNC machine tool slides, robotic arms, and automated assembly systems requiring high-speed, repeatable movements. In automotive systems, they are deployed in precision welding robots, engine component testing equipment, and electric vehicle battery manufacturing lines for their durability and resistance to vibration. For precision equipment, the SKR33 series excels in semiconductor manufacturing devices, optical alignment systems, and medical diagnostic instruments, where minimal friction and high accuracy are critical. The robust construction, coupled with optional seals for harsh environments, ensures reliable performance in industries like aerospace and packaging machinery, where downtime reduction and precision are paramount.

THK's LM Guide Actuator SKR33 series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with the driven functionality of an actuator system. This design incorporates a motor wrap, long nut, and block configurations (A and B SERIES) to deliver a compact, high-performance solution for automated linear positioning. The core of the system is the Caged Ball LM Guide, where balls are retained in a cage structure within the LM block and guide rail. This caged ball design prevents ball-to-ball contact, reducing friction, heat generation, and wear, while ensuring smooth, quiet motion even at high speeds. The actuator mechanism, driven by a motor, translates rotational force into precise linear movement through a precision ball screw assembly, with the long nut providing enhanced support and load distribution.

Key technical features include the caged ball retention system, which maintains ball circulation efficiency and eliminates the need for re-lubrication in many applications, extending maintenance intervals. The SKR33 actuator is engineered for high rigidity and accuracy, with the LM block and rail constructed from high-carbon chromium bearing steel, hardened and precision-ground to achieve tight tolerances and minimal deflection under load. The motor wrap integration allows for direct coupling with servo or stepper motors, facilitating easy installation and compact system design. The long nut design increases the number of loaded balls in contact with the screw shaft, boosting load capacity and rigidity while minimizing elastic deformation. Available in A and B SERIES block types, these actuators offer flexibility in mounting configurations and load orientations, with options for standard or sealed versions to suit varying environmental conditions.

Performance advantages are substantial, starting with exceptional positioning accuracy and repeatability, critical for precision automation tasks. The low friction coefficient of the caged ball system results in high mechanical efficiency, reducing power consumption and heat buildup, which contributes to consistent performance over long operational cycles. High-speed capability is another standout feature, with the design accommodating rapid traverse rates without sacrificing smoothness or generating excessive noise. The robust construction ensures high load capacity in all directions—radial, reverse-radial, and lateral—making it suitable for applications involving moment loads. Durability is enhanced by the optimized ball recirculation path and high-quality materials, leading to an extended service life even in demanding, high-cycle environments.

Typical applications span multiple industries where reliable, precise linear motion is paramount. In industrial machinery, the SKR33 actuator is commonly deployed in CNC machine tools for tool changing mechanisms, in semiconductor manufacturing equipment for wafer handling and positioning, and in assembly automation for pick-and-place operations. Within automotive systems, it finds use in robotic welding and painting arms, engine component testing fixtures, and automated assembly lines for precise part transfer. For precision equipment, it is integral to medical device manufacturing systems, optical instrument alignment stages, and coordinate measuring machines (CMMs) where sub-millimeter accuracy is essential. Its versatility, combined with THK's reputation for reliability, makes it a preferred choice for engineers seeking to enhance productivity and precision in dynamic motion control applications.