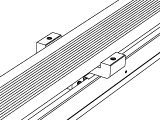

The THK LM Guide Actuator Caged Ball LM Guide Actuator SKR46 with Long Nut Block A represents a high-precision linear motion solution engineered for demanding applications requiring exceptional rigidity, smooth operation, and long-term accuracy. This system integrates a recirculating ball screw mechanism within a compact LM guide assembly, where the balls are uniquely contained within a cage structure. This caged ball design is fundamental to its performance, preventing ball-to-ball contact and minimizing friction, heat generation, and wear, even under high-speed operation or with insufficient lubrication. The SKR46 designation specifies a robust 46mm rail width, providing a substantial load-bearing capacity for its compact envelope.

Key technical features define its superior performance. The incorporation of the Long Nut Block A significantly increases the number of load-carrying balls in contact with the screw shaft. This design enhancement directly translates to a higher dynamic load rating and greater rigidity, allowing the actuator to withstand higher moments and forces with minimal deflection. The precision-ground ball screw within the actuator ensures high positional accuracy and repeatability. Furthermore, the LM guide component features four rows of balls arranged in a Gothic arch groove configuration, offering equal load capacity in all directions—radial, reverse-radial, and lateral. This provides excellent stability and smooth, low-friction linear motion with high stiffness.

The performance advantages of this system are substantial for machine designers and operators. The combination of the caged ball technology and the long nut block results in dramatically extended service life and maintenance intervals. It exhibits lower torque variation and more consistent running performance over time compared to standard nut designs. The high rigidity ensures minimal lost motion, which is critical for precision machining and positioning tasks. Its compact, integrated design simplifies machine assembly, reduces the number of components, and saves valuable space within the machine footprint.

Typical applications for the THK SKR46 LM Guide Actuator are found in sectors where precision, reliability, and durability are non-negotiable. In industrial machinery, it is ideally suited for high-precision CNC machining centers, automated assembly robots, and high-speed pick-and-place systems. Within the automotive industry, this actuator is deployed in precision welding equipment, automated painting lines, and high-accuracy parts transfer systems. For precision equipment, it serves as a core component in semiconductor manufacturing apparatus, such as wafer steppers and wire bonders, as well as in precision inspection and measurement machines where micron-level accuracy is essential. Its robust construction and high-performance characteristics make it a cornerstone for advancing automation and precision in modern manufacturing.

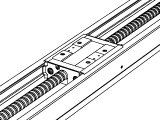

The THK LM Guide Actuator Caged Ball LM Guide Actuator SKR46 with Short Nut Block C represents a significant advancement in linear motion technology, engineered for applications demanding high precision, rigidity, and reliability. This actuator integrates a caged ball design within its LM guide mechanism, where balls are retained in a cage to prevent mutual contact, reducing friction, heat generation, and wear. The SKR46 model features a compact short nut block (Block C) that minimizes overall length while maintaining robust load capacity, making it ideal for space-constrained installations. Key technical features include a precision-ground raceway for smooth motion, high rigidity due to optimized contact angles, and preloaded ball circuits that eliminate backlash for exceptional positional accuracy. The caged ball system ensures consistent lubrication retention and lowers noise levels during operation, enhancing longevity in high-cycle environments.

Performance advantages of this actuator are substantial, starting with its ability to handle high loads in all directions—radial, reverse-radial, and lateral—thanks to its four-row circular arc groove design. It offers a high permissible moment load, ensuring stability under complex force conditions, and achieves positioning accuracy within microns, critical for precision tasks. The low friction coefficient of the caged balls results in smoother motion, reduced stick-slip, and higher efficiency, which translates to lower power consumption and less heat buildup. Additionally, the short nut block design allows for quicker installation and easier maintenance, as it reduces the overall footprint without sacrificing stroke length or durability. This actuator is built for high-speed operation with minimal vibration, supported by THK's corrosion-resistant treatments and sealing options that protect against contaminants like dust and chips.

Typical applications span various industries where precision and reliability are paramount. In industrial machinery, it is commonly used in CNC machining centers for tool positioning, automated assembly lines for precise part handling, and semiconductor manufacturing equipment where clean, vibration-free motion is essential. Within automotive systems, this actuator finds roles in robotic welding arms, engine component testing rigs, and automated paint systems that require repeatable, accurate movements. For precision equipment, it is employed in medical devices such as MRI scanner tables, optical alignment systems in lithography, and coordinate measuring machines (CMMs) that depend on sub-micron accuracy. Overall, the THK SKR46 Caged Ball LM Guide Actuator with Short Nut Block C delivers a blend of compact design, high performance, and durability, making it a versatile solution for advancing automation and precision across diverse sectors.

The THK LM Guide Actuator Caged Ball LM Guide Actuator SKR46 with Long Nut Block A represents a high-precision linear motion solution engineered for demanding applications requiring exceptional rigidity, smooth operation, and long-term accuracy. This system integrates a recirculating ball screw mechanism within a compact LM guide assembly, where the balls are uniquely contained within a cage structure. This caged ball design is fundamental to its performance, preventing ball-to-ball contact and minimizing friction, heat generation, and wear, even under high-speed operation or with insufficient lubrication. The SKR46 designation specifies a robust 46mm rail width, providing a substantial load-bearing capacity for its compact envelope.

Key technical features define its superior performance. The incorporation of the Long Nut Block A significantly increases the number of load-carrying balls in contact with the screw shaft. This design enhancement directly translates to a higher dynamic load rating and greater rigidity, allowing the actuator to withstand higher moments and forces with minimal deflection. The precision-ground ball screw within the actuator ensures high positional accuracy and repeatability. Furthermore, the LM guide component features four rows of balls arranged in a Gothic arch groove configuration, offering equal load capacity in all directions—radial, reverse-radial, and lateral. This provides excellent stability and smooth, low-friction linear motion with high stiffness.

The performance advantages of this system are substantial for machine designers and operators. The combination of the caged ball technology and the long nut block results in dramatically extended service life and maintenance intervals. It exhibits lower torque variation and more consistent running performance over time compared to standard nut designs. The high rigidity ensures minimal lost motion, which is critical for precision machining and positioning tasks. Its compact, integrated design simplifies machine assembly, reduces the number of components, and saves valuable space within the machine footprint.

Typical applications for the THK SKR46 LM Guide Actuator are found in sectors where precision, reliability, and durability are non-negotiable. In industrial machinery, it is ideally suited for high-precision CNC machining centers, automated assembly robots, and high-speed pick-and-place systems. Within the automotive industry, this actuator is deployed in precision welding equipment, automated painting lines, and high-accuracy parts transfer systems. For precision equipment, it serves as a core component in semiconductor manufacturing apparatus, such as wafer steppers and wire bonders, as well as in precision inspection and measurement machines where micron-level accuracy is essential. Its robust construction and high-performance characteristics make it a cornerstone for advancing automation and precision in modern manufacturing.