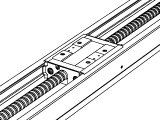

THK's LM Guide Actuator SKR46 Series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with the compact efficiency of a motor wrap and short nut design. This actuator features a robust Block C D configuration with an integrated cover, engineered to deliver exceptional performance in demanding applications. The caged ball retainer system is a key innovation, where balls are securely held in a polymer cage to prevent contact and friction between them, reducing noise, heat generation, and wear. This design ensures smooth, consistent motion with minimal maintenance requirements, even at high speeds or under heavy loads.

Technical features of the SKR46 Series include a compact short nut that minimizes overall length while maintaining high load capacity and rigidity. The motor wrap allows for seamless integration with servo or stepper motors, enabling precise positioning and repeatability. The Block C D with Cover provides enhanced protection against contaminants like dust, chips, and moisture, extending service life in harsh environments. With pre-loaded ball screws and optimized recirculation paths, this actuator achieves high accuracy, with positional repeatability often within microns. Additionally, it supports high-speed operation and offers excellent resistance to vibration and shock, making it suitable for dynamic industrial settings.

Performance advantages stem from its ability to combine high precision with durability. The caged ball design reduces torque variation and ensures consistent linear motion, which is critical for applications requiring smooth acceleration and deceleration. This results in improved energy efficiency, reduced downtime, and longer operational life compared to conventional linear guides. The compact footprint of the SKR46 Series allows for space-saving installations in machinery with limited real estate, while its high load capacity supports both radial and moment loads effectively. Maintenance is simplified due to the sealed design and reduced lubrication needs, lowering total cost of ownership.

Typical applications span various high-precision industries. In industrial machinery, it is used in CNC machining centers for tool positioning, automated assembly lines for precise part handling, and packaging equipment for rapid, accurate movements. In automotive systems, the actuator contributes to robotics for welding and painting processes, as well as in testing rigs for component validation. For precision equipment, it finds use in semiconductor manufacturing for wafer handling, medical devices for imaging systems, and optical instruments where stable, vibration-free motion is essential. Overall, the THK LM Guide Actuator SKR46 Series delivers reliability and precision, driving efficiency in modern automation and manufacturing environments.

THK's LM Guide Actuator SKR46 Series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with an actuator mechanism designed for high-load, high-speed applications. This series features a motor wrap configuration, long nut block assemblies (available in Type A and Type B variants), and protective covers to ensure durability in demanding environments. The core innovation lies in its caged ball design, where rolling elements are securely contained within precision-engineered cages, preventing direct ball-to-ball contact and minimizing friction, heat generation, and wear. This construction allows for smoother motion, reduced maintenance intervals, and extended service life compared to conventional linear guides.

Key technical features include the SKR46's robust rail and block structure, capable of supporting significant moment loads and radial forces. The long nut block enhances load distribution and provides superior alignment stability, critical for applications requiring repeatable accuracy. Motor wrap integration facilitates direct coupling with servo or stepper motors, enabling precise positional control and rapid response times. The inclusion of Type A and Type B block options offers flexibility in mounting configurations and load capacities, while integrated seals and covers protect against contaminants like dust, chips, and moisture—a vital attribute for harsh industrial settings.

Performance advantages are evident in the actuator's ability to maintain micron-level precision under high acceleration and velocity. The caged ball system reduces noise and vibration, contributing to smoother operation and improved positioning accuracy. With preloaded ball circuits, the SKR46 minimizes backlash, ensuring consistent performance in bidirectional movements. Its high rigidity and damping characteristics make it suitable for dynamic applications where shock resistance is paramount. Additionally, the lubricant-retention design prolongs lubrication intervals, reducing downtime and operational costs.

Typical applications span multiple sectors, including industrial automation where the SKR46 is deployed in CNC machining centers for tool positioning, robotic arm articulation, and automated assembly lines requiring precise linear traversal. In automotive manufacturing, it facilitates tasks such as welding gun manipulation, part transfer systems, and precision testing equipment. The series also excels in precision equipment like semiconductor handling robots, medical device actuators, and optical alignment systems, where cleanliness, reliability, and sub-millimeter accuracy are non-negotiable. By delivering a blend of durability, precision, and adaptability, the THK LM Guide Actuator SKR46 Series addresses the evolving needs of modern industrial machinery, enhancing productivity and operational efficiency across diverse applications.

The THK LM Guide Actuator SKR46 series represents a sophisticated integration of linear motion technology, combining a Caged Ball LM Guide with a precision ball screw actuator in a compact, high-performance package. This system features a short nut block design from the C/D SERIES, optimized for space-constrained applications while maintaining exceptional load capacity and positioning accuracy. The caged ball technology within the LM guide ensures smooth, consistent motion by retaining the balls in precision-formed cages, preventing direct contact and reducing friction, wear, and noise even under high-speed operation or rapid reciprocating movements.

Key technical features include the use of a motor wrap configuration that allows for direct motor mounting, simplifying assembly and enhancing rigidity. The SKR46 actuator is engineered with a preloaded ball screw and guide mechanism, delivering high stiffness and minimal backlash for precise linear positioning. Its compact short nut block minimizes the overhang length, making it ideal for installations where space is at a premium. The caged ball design not only improves lubrication retention but also significantly extends service life by preventing ball-to-ball contact and reducing heat generation. Additionally, the LM guide offers high load capacity in all directions—radial, reverse-radial, and lateral—ensuring stability under complex force conditions.

Performance advantages are evident in its ability to achieve high-speed linear motion with repeatability accuracies within micrometers. The reduced friction from the caged balls translates to lower driving torque requirements, enhancing energy efficiency and allowing for the use of smaller motors. The actuator's rigidity and damping characteristics minimize vibration and deflection, critical for maintaining precision in dynamic applications. Its sealed design with integrated wipers protects against contaminants like dust and chips, ensuring reliable operation in harsh environments. Maintenance intervals are extended due to efficient lubrication distribution and reduced wear.

Typical applications span across industrial machinery, where the SKR46 actuator is employed in CNC machining centers for tool changers, feed mechanisms, and automated pallet systems. In automotive manufacturing, it facilitates precise positioning in robotic welding arms, assembly line conveyors, and testing equipment. The precision equipment sector utilizes these actuators in semiconductor manufacturing for wafer handling robots, optical alignment stages, and coordinate measuring machines. Its compact design and high reliability also make it suitable for medical devices, packaging machinery, and electronic component assembly, where space efficiency and accuracy are paramount. The THK LM Guide Actuator SKR46 series thus delivers a robust solution for demanding linear motion needs, balancing performance, durability, and compactness.

THK's LM Guide Actuator series, including the Caged Ball LM Guide Actuator models such as the SKR46 with integrated motor, long nut, and Block A/B SERIES configurations, represents a sophisticated integration of linear motion components engineered for high precision, rigidity, and reliability in demanding applications. These actuators combine THK's renowned LM Guide technology with a ball screw drive mechanism, encapsulated within a compact unit that facilitates smooth, accurate linear movement under substantial loads. The SKR46 variant, in particular, features a caged ball design that separates rolling elements with a retainer, reducing friction, minimizing heat generation, and enabling higher speeds compared to conventional designs. This design also enhances durability by preventing ball-to-ball contact, which can lead to wear and noise over time.

Key technical features include the use of a long nut configuration in the ball screw assembly, which increases the number of engaged threads to distribute load more evenly, thereby improving positional accuracy and extending service life. The Block A and B SERIES refer to specific housing designs that optimize mounting flexibility and load capacity; Block types typically offer enhanced rigidity for moment loads, making them suitable for applications requiring stability under complex force conditions. Integration with a motor—often a servo or stepper type—allows for precise control of linear positioning, with the actuator capable of handling thrust loads up to several kilonewtons and speeds exceeding 1 m/s, depending on the model and lubrication. Preloaded ball grooves in the LM Guide ensure minimal backlash and high repeatability, with accuracy grades reaching within micrometers per 300 mm travel.

Performance advantages stem from this robust construction: the caged ball system reduces maintenance intervals by up to 50% in high-cycle operations, while the corrosion-resistant materials and sealing options (such as scrapers and seals) protect against contaminants in harsh environments like automotive welding lines or machining centers. The actuator's compact footprint saves space in machinery layouts, and its high efficiency translates to lower energy consumption for equivalent output. Additionally, the integrated motor wrap simplifies installation, reducing assembly time and potential misalignment issues.

Typical applications span industrial machinery, where these actuators drive axes in CNC machining centers, robotic arms for pick-and-place tasks, and automated assembly systems requiring precise linear positioning. In the automotive sector, they are employed in brake forming presses, engine component testing rigs, and electric vehicle battery module handling equipment, where high load capacity and durability under frequent starts and stops are critical. For precision equipment, the SKR46 actuator finds use in semiconductor manufacturing tools, optical alignment stages, and medical device automation, leveraging its smooth motion and sub-micron accuracy to ensure product quality and process consistency. Overall, THK's LM Guide Actuator series delivers a reliable, high-performance solution for applications demanding exact linear control in challenging operational conditions.