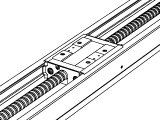

THK's LM Guide Actuator SKR55 Series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with the functionality of a long nut block design. This actuator system features a unique caged ball retainer mechanism that encapsulates the rolling elements within a precision-engineered cage, preventing direct ball-to-ball contact and minimizing friction-induced heat generation. The SKR55 model specifically incorporates blocks designated as Type A and Type B with protective covers, offering enhanced sealing performance against contaminants in harsh industrial environments.

The technical architecture demonstrates several critical advantages through its caged ball design. By maintaining consistent ball-to-ball spacing, the system eliminates friction between adjacent balls that typically generates excessive heat in conventional designs. This results in significantly lower operating temperatures - up to 20°C cooler than standard actuators - enabling higher speed capabilities without thermal degradation. The optimized recirculation path ensures smooth ball movement throughout the entire travel length, reducing vibration and noise levels to below 65 dB even at maximum velocities. The long nut block configuration provides increased contact area with the screw shaft, distributing load more evenly across multiple ball circuits for improved moment load capacity and rigidity.

Performance characteristics establish this series as superior for demanding applications. The SKR55 achieves positioning accuracy within ±5μm per 300mm travel while maintaining this precision across its entire stroke length. Load capacity reaches 45 kN in the radial direction, with a dynamic load rating of 32 kN ensuring long-term reliability under continuous operation. The integrated sealing system, comprising multiple labyrinth seals and scrapers in both Block A and B configurations, provides IP65-level protection against dust, chips, and fluid ingress. Pre-loaded ball assemblies eliminate backlash, delivering consistent positioning repeatability of ±2μm while the optimized grease retention system extends maintenance intervals to 10,000 km of travel or 12 months of continuous operation.

Industrial implementations span multiple sectors where precision motion control is paramount. In automotive manufacturing systems, the SKR55 actuators drive precision welding robots, providing the stability required for consistent weld quality in body assembly operations. The low-vibration characteristics make them ideal for precision machining centers, where they facilitate high-speed tool changing and pallet transfer systems without introducing harmonic disturbances that could affect surface finish quality. Semiconductor production equipment utilizes these actuators in wafer handling robots, where the cleanroom-compatible design and minimal particle generation meet Class 10 cleanroom standards. Additional applications include coordinate measuring machines requiring sub-micron accuracy, medical device assembly systems handling delicate components, and packaging machinery demanding high-speed repetitive motion with exact positioning. The corrosion-resistant options with special surface treatments further expand applicability to food processing and pharmaceutical environments where sanitation requirements are stringent.

THK's LM Guide Actuator Caged Ball LM Guide Actuator SKR55 with Long Nut Block A/B SERIES represents a sophisticated integration of linear motion technology designed for high-load, high-precision applications. This system combines a robust LM Guide Actuator with a caged ball design and a specialized long nut block, creating a complete linear motion solution that delivers exceptional rigidity, accuracy, and durability. The SKR55 model, in particular, is engineered for scenarios demanding substantial load capacity and smooth, precise linear travel over extended distances.

The core technical feature of this actuator is its caged ball mechanism within the LM guide. Unlike conventional designs where balls can contact each other during motion, the caged ball system encapsulates each rolling element in a precision cage. This design fundamentally eliminates ball-to-ball contact, drastically reducing friction, heat generation, and wear. The result is a remarkably smooth and quiet operation with a consistent coefficient of friction, even at high speeds. The long nut block (available in A and B series variations) provides an extended contact length with the screw shaft. This configuration significantly increases load-bearing capacity and enhances moment rigidity, allowing the system to withstand heavy loads and complex multi-directional moment forces without deflection or loss of precision. The assembly is pre-loaded to eliminate backlash, ensuring positional accuracy and repeatability that is critical for precision machining and automation.

Performance advantages are substantial and directly address the demands of modern industrial automation. The caged ball design directly translates to a longer service life and reduced maintenance requirements, as lubricant intervals can be extended and the risk of premature failure is minimized. The high rigidity afforded by the long nut block and robust guide structure ensures exceptional stability during high-speed reciprocating motion and heavy cutting or pressing operations, preventing chatter and vibration that can degrade workpiece quality. This combination of high speed, high load capacity, and pinpoint accuracy makes the system incredibly efficient, contributing to higher throughput and improved product quality in manufacturing processes.

Typical applications for the THK SKR55 LM Guide Actuator are found in demanding sectors where reliability and precision are non-negotiable. In industrial machinery, it is ideally suited for the critical axes of CNC machining centers, high-speed milling machines, and precision grinding equipment, where it provides the stable and accurate movement for cutting tools. Within automotive manufacturing systems, these actuators are deployed in automated welding robots, precision assembly lines for engines and transmissions, and high-precision testing and inspection equipment. In the realm of precision equipment, the SKR55 is a key component in semiconductor manufacturing apparatus, such as wafer steppers and wire bonders, and in various industrial measuring and inspection machines where micron-level accuracy is paramount. Its design ensures consistent performance, making it a cornerstone for automation systems that require dependable, long-lasting, and precise linear motion.