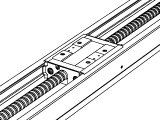

The THK LM Guide Actuator Caged Ball LM Guide Actuator SKR65 Long Nut Block A B with Cover SERIES represents a sophisticated evolution in linear motion technology, engineered for applications demanding exceptional precision, rigidity, and longevity. This system integrates a recirculating ball screw mechanism with a robust LM guide, where the balls are uniquely contained within a cage structure. This caged ball design is a pivotal technical feature, fundamentally reducing friction, minimizing heat generation, and preventing ball-to-ball contact, which drastically cuts operational noise and enhances the system's service life. The SKR65 designation specifies a model with a 65mm nominal width, indicating its capacity for handling substantial loads and moments.

Key performance advantages stem directly from its construction. The incorporation of the long nut block—available in Type A and Type B configurations—significantly increases the number of load-carrying balls in contact with the screw shaft. This design choice dramatically improves axial rigidity, positioning accuracy, and load capacity compared to standard nut designs. The included cover is a critical component for reliability, effectively sealing the ball screw and LM guideway from pervasive environmental contaminants such as dust, chips, and moisture. This robust sealing ensures consistent performance and prevents premature wear in harsh operating conditions. The system is pre-loaded for high stiffness, resulting in minimal axial clearance and exceptional repeatability, which is crucial for precision positioning tasks. Its high-efficiency ball screw mechanism also allows for high-speed movement without sacrificing accuracy or generating excessive heat.

Typical applications for this actuator series are found in high-performance industrial sectors. In industrial machinery, it is indispensable for the precise axis movement in CNC machining centers, high-speed pick-and-place robots, and automated assembly lines where speed, precision, and uptime are paramount. Within automotive manufacturing systems, these actuators provide the reliable motion control needed for precision welding robots, automated material handling systems, and rigorous testing equipment. For precision equipment, the SKR65 series is ideally suited for applications such as semiconductor manufacturing apparatus, precision optical alignment systems, and advanced medical diagnostic equipment, where micron-level accuracy, smooth motion, and long-term reliability are non-negotiable requirements. This combination of advanced caged ball technology, enhanced load capacity through the long nut, and integrated protection makes the THK SKR65 series a cornerstone component for advancing automation and precision in modern manufacturing and technology development.

THK's LM Guide Actuator Caged Ball LM Guide Actuator SKR65, paired with the Long Nut Block A and B SERIES, represents a pinnacle of precision linear motion engineering, designed to deliver exceptional rigidity, accuracy, and longevity in demanding industrial applications. This system integrates a recirculating ball-based linear guide mechanism with an actuator-driven design, where the SKR65 model denotes a specific size and load capacity optimized for heavy-duty operations. The caged ball technology ensures that rolling elements are uniformly spaced and retained within a dedicated cage, minimizing friction, reducing heat generation, and preventing ball-to-ball contact, which significantly enhances operational smoothness and extends service life. The Long Nut Block variants (A and B SERIES) provide extended nut lengths for increased load distribution and higher moment resistance, making them ideal for applications requiring sustained precision under substantial forces.

Key technical features include a robust steel construction with precision-ground raceways for consistent ball recirculation, ensuring minimal deviation and high repeatability. The actuator component enables controlled linear movement with integrated drive mechanisms, often compatible with servo or stepper motors for precise positioning. Advanced sealing systems protect against contaminants like dust, chips, and moisture, maintaining performance in harsh environments. Pre-load adjustment capabilities allow for fine-tuning to eliminate backlash and enhance stiffness, while the compact design of the SKR65 facilitates space-saving integration into machinery layouts. Performance advantages are substantial, with the system offering high load capacities—supporting radial, reverse radial, and moment loads—coupled with low noise and vibration levels. This results in improved efficiency, reduced maintenance intervals, and energy savings due to optimized friction characteristics. The caged ball design also contributes to higher speeds and accelerations without compromising accuracy, achieving positioning precision within micrometers.

Typical applications span across industrial machinery, where these components are employed in CNC machining centers for tool positioning, automated assembly lines for precise part handling, and semiconductor manufacturing equipment requiring sub-micron accuracy. In automotive systems, they are utilized in robotic welding arms, engine component testing rigs, and automated paint systems, where durability and repeatability are critical. Precision equipment sectors, such as medical device manufacturing or optical alignment systems, benefit from the actuator's smooth motion and minimal particulate generation, ensuring cleanroom compatibility. Overall, the THK LM Guide Actuator SKR65 with Long Nut Block A/B SERIES provides a reliable, high-performance solution for applications demanding rigorous linear motion control, contributing to enhanced productivity and reduced downtime in advanced automation environments.