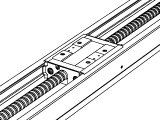

THK's LM Guide Actuator SKR65 series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with the driven functionality of an actuator. This system features a motor wrap design and incorporates a long nut block in both A and B series configurations, engineered to deliver exceptional accuracy, rigidity, and longevity in demanding applications. The Caged Ball technology is a standout feature, where balls are retained in a cage within the LM guide, preventing contact between them and minimizing friction, heat generation, and wear. This design ensures smooth, quiet operation and extends service life, even under high-load or high-speed conditions. The actuator's construction includes precision-ground raceways and a optimized ball circulation system, which contribute to consistent performance and minimal maintenance requirements.

Performance advantages of the SKR65 series are substantial, offering high positioning accuracy and repeatability, making it ideal for applications where precise linear movement is critical. Its robust design supports heavy loads and moments, providing stability and resistance to vibration, which enhances overall system reliability. The inclusion of a long nut block in the A and B series allows for efficient force transmission and ease of installation, reducing assembly time and complexity. Additionally, the motor wrap feature integrates seamlessly with various motor types, facilitating compact system designs and improved energy efficiency. These actuators are known for their low noise levels and ability to operate in harsh environments, including those with contaminants, thanks to optional seals and protective covers.

In industrial machinery, the THK LM Guide Actuator SKR65 is commonly employed in automation systems, such as pick-and-place robots, CNC machine tools, and assembly lines, where it ensures precise part handling and machining operations. In the automotive sector, it finds use in welding equipment, painting robots, and engine assembly systems, contributing to high-speed production with minimal downtime. For precision equipment, this actuator is utilized in semiconductor manufacturing devices, medical imaging systems, and optical positioning stages, where its accuracy and smooth motion are essential for achieving micron-level tolerances. Overall, the SKR65 series delivers a reliable, high-performance solution that enhances productivity and reduces total cost of ownership across diverse industrial applications.

The THK LM Guide Actuator SKR65 series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with an actuator mechanism designed for high-load, high-precision applications. This system features a motor wrap, long nut, and block configurations (A and B) with protective covers, engineered to deliver exceptional rigidity, accuracy, and durability in demanding environments. At its core, the Caged Ball LM Guide utilizes a unique caged ball retainer system that separates adjacent balls, minimizing friction, reducing heat generation, and effectively preventing metal-to-metal contact. This design ensures smooth, consistent motion with minimal vibration, even under high-speed or heavy-load conditions. The actuator component, incorporating a precision-ground ball screw and long nut, provides efficient torque transmission and backlash control, while the motor wrap facilitates seamless integration with servo or stepper motors for automated positioning tasks. Blocks A and B offer versatile mounting options, with covers that shield critical components from contaminants like dust, chips, and moisture, extending service life in harsh industrial settings.

Key technical features include the caged ball retainer for enhanced lubrication retention and reduced maintenance intervals, high load capacity supported by optimized raceway geometry, and precision machining for tight tolerances and repeatable positioning. The SKR65 series excels in performance advantages such as superior stiffness for minimal deflection under load, low noise operation due to controlled ball circulation, and extended operational life with reliable, maintenance-free intervals. Its corrosion-resistant coatings and sealed designs make it suitable for environments where exposure to coolants or particulates is common.

Typical applications span across industrial machinery, where these actuators are deployed in CNC machining centers for tool changer systems, automated assembly lines for precise part handling, and semiconductor manufacturing equipment requiring micron-level accuracy. In automotive systems, they facilitate operations in robotic welding arms, engine component testing rigs, and brake assembly lines, where high cycle rates and durability are paramount. For precision equipment, the SKR65 series is ideal for optical alignment devices, medical imaging systems, and coordinate measuring machines, leveraging its smooth motion and positional stability to ensure consistent, error-free performance. By integrating these components, engineers achieve optimized motion control solutions that enhance productivity, reduce downtime, and support the advancement of automation across diverse sectors.