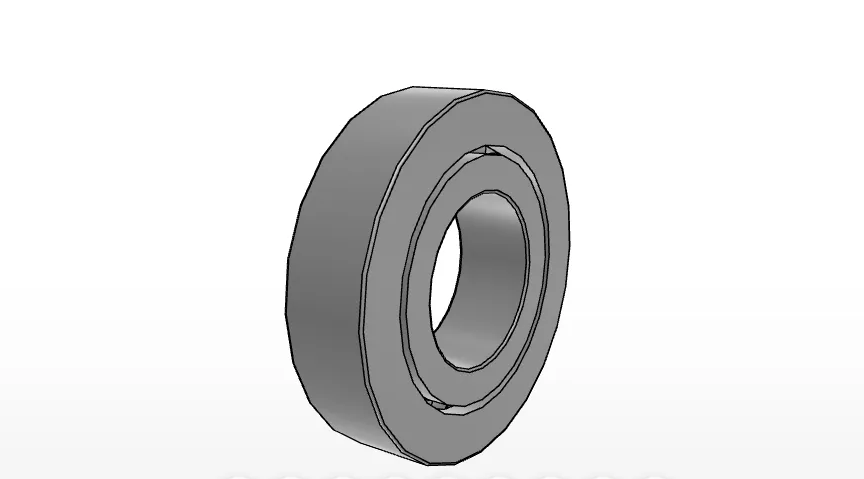

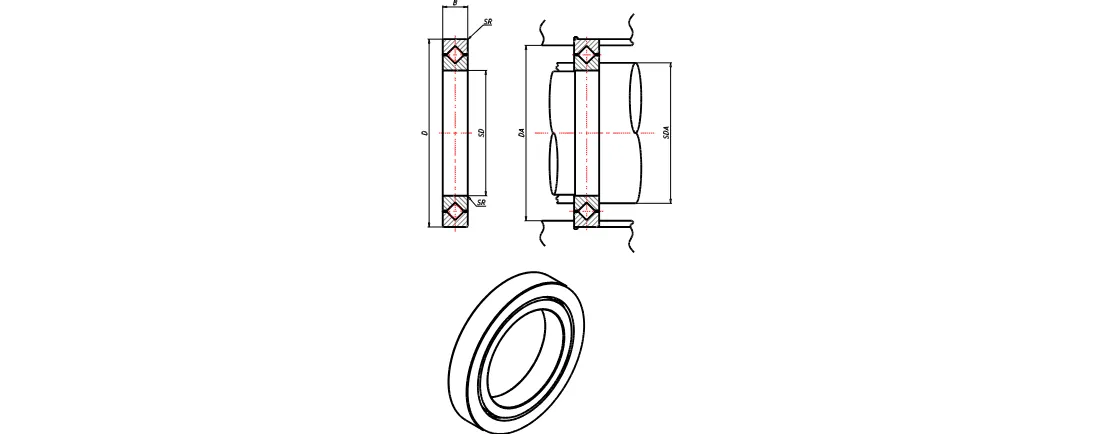

IKO crossed roller bearings are different from standard bearings due to their unique design. Inside the bearing, cylindrical rollers are placed each other in a crisscross pattern at right angles. This arrangement allows the effect to support load in many directions at the same time. Unlike regular ball bearings, which can only handle radial or axial loads, crossed roller bearings can manage radial, axial, and moment loads with high accuracy.

Another unique factor is the rigidity of these bearings. Machines such as robots, medical equipment and other equipment require bearings that do not allow additional movement. With precision crossed roller bearings, rollers are tightly arranged, the gap is reduced and stiffness increases. This means that the machine can work with greater accuracy and stability.

Premium IKO crossed roller bearing is available

High rigidity and weight capacity

IKO crossed roller bearings are designed to give excellent rigidity and strength. With rollers arranged at right angles with rollers, they can handle radial, axial and moment loads at the same time. This unique design makes them strong enough to support heavy loads without losing them.

Compact structure

One of the biggest benefits of IKO high rigidity bearings is their compact size. Even in tight places, they provide excellent load capacity and stability. This feature makes them perfect for machines where both space and performance matter.

Widely used in industries.

These bearings are trusted in many areas. From industrial robots to medical devices, and from machining centers to accurate equipment, they provide stable and reliable performance. Their accuracy also ensures smooth operation in high-tech applications.

Easy installation and long-term stability

IKO simplifies the installation by designing the internal and external rings as a unit. This saves time and makes maintenance easier. With proper care, these bearings provide long-term stability, which ensures frequent performance for years.

Major features of high-rigidity cross roller bearings

One of the most important features of IKO crossed roller bearings is high hardness. Cruscross due to roller design, bearing also opposes deformation under heavy loads. This hardness ensures that machines can work with high precision, especially in industries where accuracy is important.

Another major feature is smooth rotation. Rollers are carefully placed to reduce friction, resulting in smooth and stable speed. It is important for machines such as robotic weapons or measuring devices that require accurate movements.

The compact design is another highlight. These compact roller bearing designs are smaller in size than other bearing types that provide similar performance. This compact structure allows engineers to design lighter and more efficient machines.

Stability also makes them stand out. IKO uses high-quality materials and advanced manufacturing techniques, which expand the lifestyle of the effect. It reduces the cost of maintenance and machine downtime.

Crossed roller bearing applications

Due to their unique characteristics, IKO crossed roller bearings are used in a wide range of industries. In robotics, they help to move robotic weapons smoothly and with accuracy. Compact size and high rigidity make them perfect for joints and rotary parts.

In medical devices, such as CT scanners or surgical machines, these bearings ensure accurate speed. Patients and doctors depend on this level of accuracy, which makes IKO a preferred option for roller bearings.

In industrial machinery, they are used in machine tools and measurement devices. For example, CNC machines depend on cross roller bearings to cut and shape the material with accuracy. Without stable bearings, even a small error can cause defects in the product.

They are also used in the aerospace and defence industries. In these areas, the equipment should handle heavy loads while being compact and reliable. IKO rotary motion bearings meet these strict requirements.

Types of roller bearing

IKO provides different types of cross roller bearings to suit various requirements. A common type of standard crossing is a roller bearing, which is widely used in industrial machines. It provides strong rigidity and a compact design for general applications.

Roller bearings are also crossed with the dividers, which keep small pieces between rollers. This reduces friction and allows the effect to move more smoothly. They are often used in applications that require high-speed rotation.

Another type is the roller bearing crossed with cages, which helps to direct rollers and maintain proper spacing. This design reduces wear and increases the life of the bearing.

Some advanced types come up with integrated internal or external rings, which simplify the installation and protect the location. These types are useful in machines where space is limited and easy assembly is important.

Each type of IKO rotary motion bearing is designed to meet specific requirements. Choosing the correct type depends on the machine’s requirements, load capacity and operating environment.

Compact and reliable bearing benefits of design

One of the biggest benefits of roller bearings compared to IKO is their compact size. Even though they are smaller than many other bearings, they can handle heavy loads from many directions. This makes them perfect for those machines that need to save space but still need strength.

Reliability is another benefit. Due to high-quality designs and materials, these bearings last longer and require less maintenance. This means low downtime and more productivity for machines.

This ability to handle complex loads is also a major benefit. Instead of using several bearings for radial, axial and moment load, a single cross roller bearing can manage all three. It not only saves space but also reduces overall machine costs.

How to select the right IKO cross roller bearing

The correct IKO crossed roller bearing depends on many factors. First of all, you should consider the load capacity. Think about whether your machine needs to handle heavy, light or mixed loads. Crossed roller bearings to match different needs come in different sizes and strengths.

Next, look at the exact requirements. If your application includes medical equipment or CNC machines, you need the effect with the highest accuracy. On the other hand, for low-demand uses, a standard type may be sufficient.

You should also consider the operating environment. If the machine works in excessive temperature or dusty areas, you need an impact designed to handle the conditions.

Installation is another factor. Some IKO industrial automation bearings are easier to establish compared to others. If your team requires quick setup and minimal adjustment, go for types with integrated rings or cages.

Always choose a reliable supplier. Buying from reliable sources ensures that you get real IKO bearings with the best performance and warranty.

Top brand to buy authentic IKO crossed roller bearings

Authenticity is very important when it comes to purchasing IKO crossed roller bearings. There are many suppliers in the market, but not all the original products can be guaranteed. This is why it is important to choose a reliable partner.

Noks is such a reliable supplier. We are committed to giving heavy load crossed roller bearing solutions to customers worldwide. With a strong reputation in the industry, Noks specialises in globally recognised brands such as SKF, FAG, Ina, NSK, NTN, Koy, IKO, Timken, Thk, and many more premium bearings and a wide range of accessories.

When you buy IKO crossed roller bearings from Noks, you may be convinced that you are getting real products, expert guidance and later support.