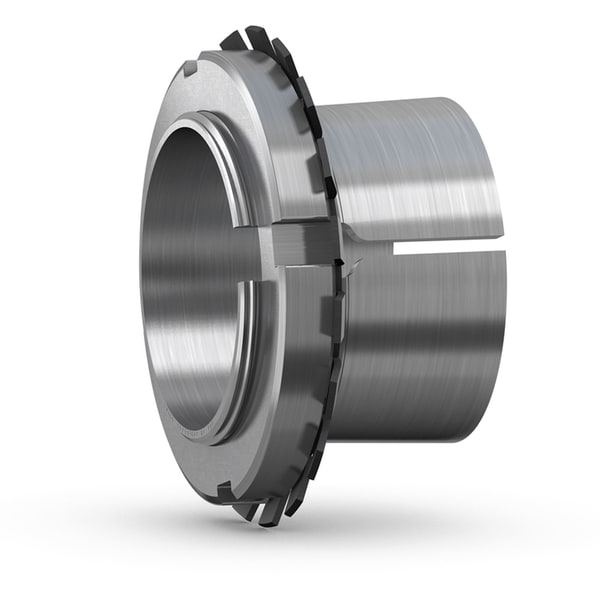

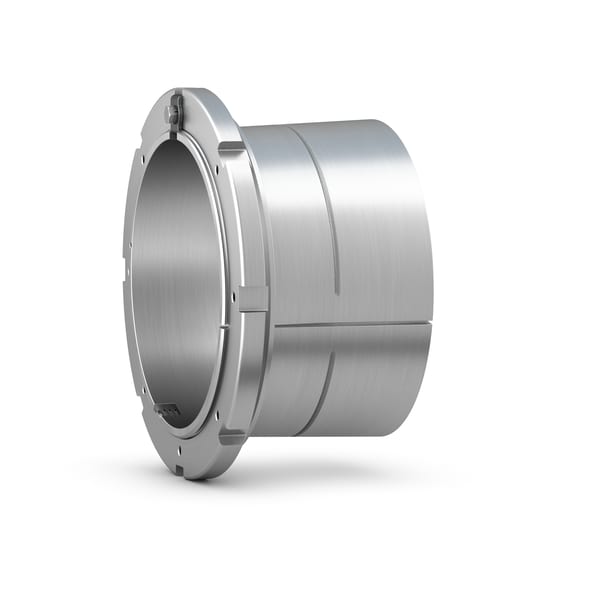

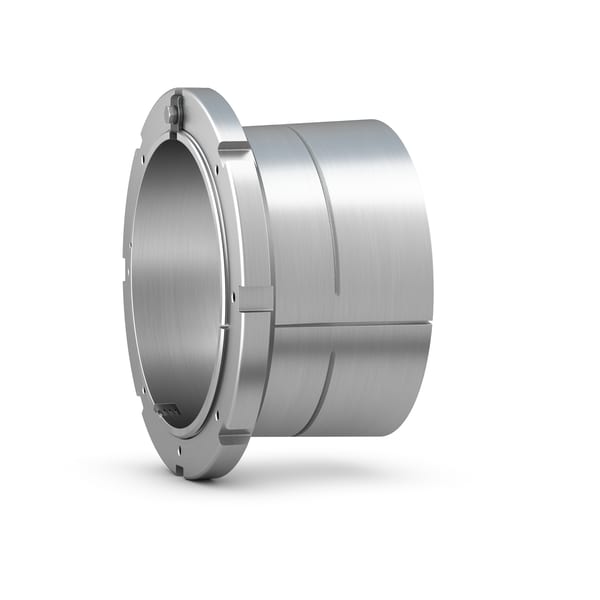

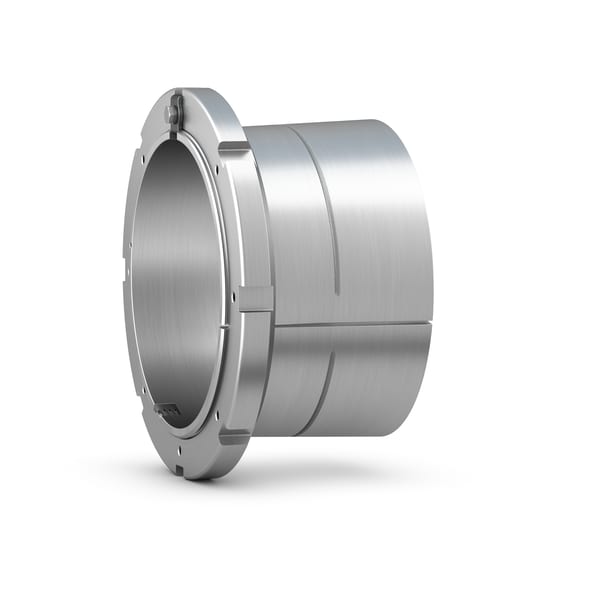

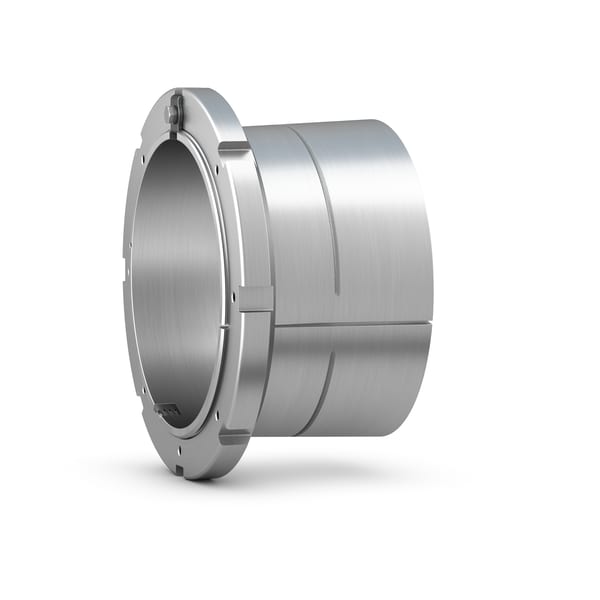

| img | Designation | Bore diameter | Width | Mass |

|---|---|---|---|---|

55.563 mm |

70.129 mm |

0.907 kg |

||

112.713 mm |

126.289 mm |

5.41 kg |

||

69.85 mm |

60.096 mm |

1.06 kg |

||

76.2 mm |

62.89 mm |

1.06 kg |

||

82.55 mm |

66.954 mm |

1.32 kg |

||

138.113 mm |

94.005 mm |

5.56 kg |

||

152.4 mm |

101.829 mm |

6.55 kg |

||

112.713 mm |

95.301 mm |

3.8 kg |

||

163.513 mm |

127.711 mm |

6.99 kg |

||

190.5 mm |

149.631 mm |

18.3 kg |

||

17.0 mm |

24.0 mm |

0.04 kg |

||

55.0 mm |

38.0 mm |

0.36 kg |

||

65.0 mm |

43.0 mm |

0.74 kg |

||

75.0 mm |

50.0 mm |

1.06 kg |

||

80.0 mm |

52.0 mm |

1.17 kg |

||

55.0 mm |

62.0 mm |

0.45 kg |

||

60.0 mm |

65.0 mm |

0.555 kg |

||

60.0 mm |

68.0 mm |

0.88 kg |

||

80.0 mm |

73.0 mm |

1.48 kg |

||

240.0 mm |

145.0 mm |

13.7 kg |

||

380.0 mm |

210.0 mm |

40.0 kg |

||

400.0 mm |

212.0 mm |

41.3 kg |

||

560.0 mm |

399.0 mm |

234.0 kg |

||

220.0 mm |

172.0 mm |

16.5 kg |