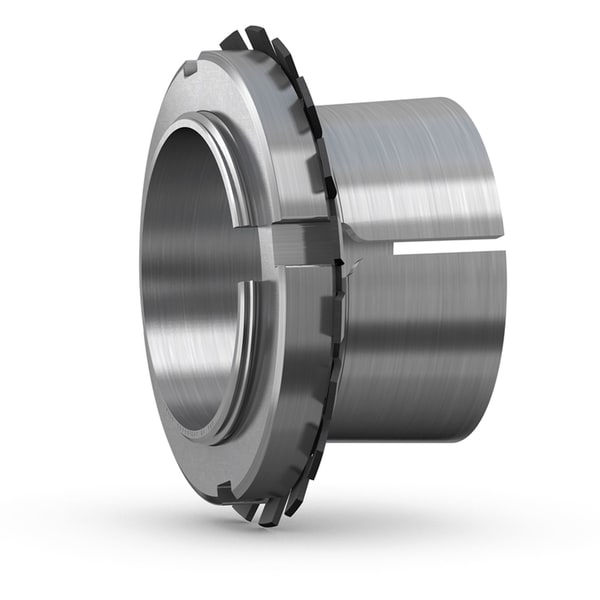

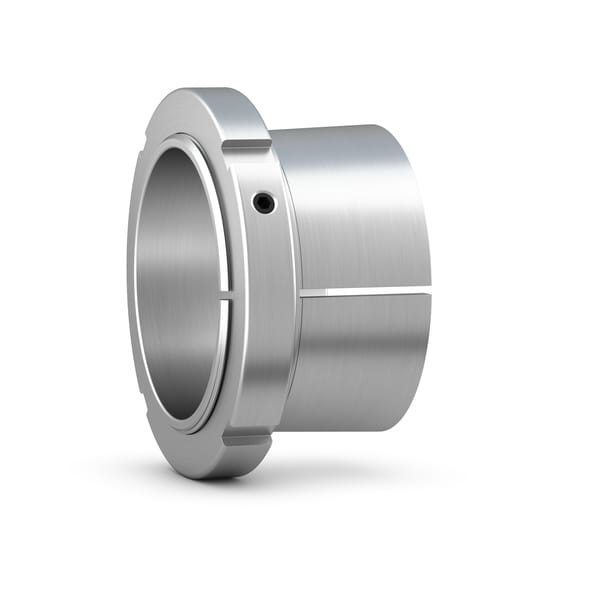

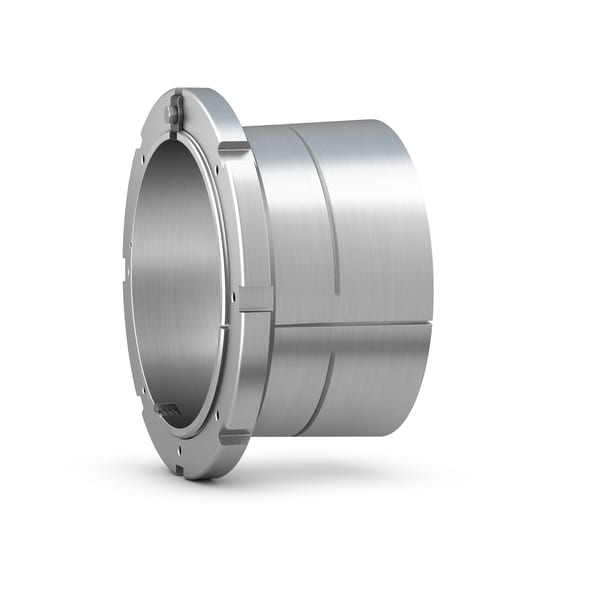

| img | Designation | Bore diameter | Width | Mass |

|---|---|---|---|---|

317.5 mm |

282.346 mm |

47.6 kg |

||

93.663 mm |

110.185 mm |

3.65 kg |

||

96.838 mm |

110.185 mm |

2.9 kg |

||

52.388 mm |

50.267 mm |

0.7 kg |

||

203.2 mm |

183.566 mm |

16.1 kg |

||

66.675 mm |

60.096 mm |

1.3 kg |

||

114.3 mm |

81.966 mm |

3.4 kg |

||

149.225 mm |

101.829 mm |

6.5 kg |

||

93.663 mm |

75.616 mm |

2.99 kg |

||

107.95 mm |

74.6 mm |

0.01 kg |

||

174.625 mm |

133.375 mm |

8.8 kg |

||

160.338 mm |

127.711 mm |

8.6 kg |

||

135.0 mm |

139.0 mm |

5.9 kg |

||

125.0 mm |

82.0 mm |

3.06 kg |

||

17.0 mm |

28.0 mm |

0.05 kg |

||

110.0 mm |

88.0 mm |

2.15 kg |

||

106.363 mm |

112.0 mm |

3.4 kg |

||

131.763 mm |

139.0 mm |

7.08 kg |

||

152.4 mm |

154.0 mm |

9.18 kg |

||

171.45 mm |

169.0 mm |

11.7 kg |

||

127.0 mm |

82.0 mm |

2.78 kg |

||

1000.0 mm |

447.0 mm |

571.0 kg |

||

600.0 mm |

254.0 mm |

119.0 kg |

||

360.0 mm |

164.0 mm |

31.7 kg |