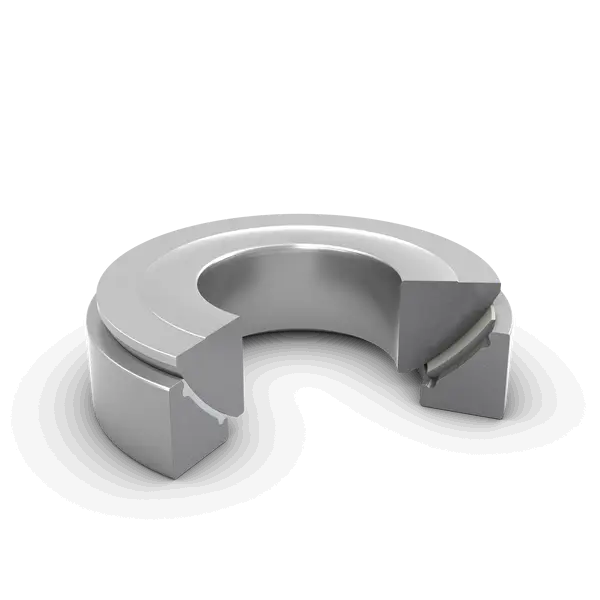

Thrust spherical plain bearings have the following features:

Construction features: Thrust spherical plain bearings consist of a convex spherical surface and a corresponding concave spherical surface. The convex surface is located on the bearing shell and the concave surface is located on the bearing seat. This design allows the bearing to withstand the main axial load, as well as combined loads (radial and axial loads), but the radial load should not exceed 50% of the axial load.

Application scenarios: Thrust spherical plain bearings are suitable for occasions where axial loads need to be carried, such as axial support in rotating machinery. When the radial load is large, it is usually necessary to combine it with a radial

"Angular Contact spherical plain bearings" or its variants (such as four-point angular contact ball bearings) are a type of bearing designed for specific application requirements, which optimizes performance by changing the contact mode between the rolling elements and the inner and outer rings. This type of bearing is very important in industrial and mechanical applications, especially in environments that require high efficiency, high load capacity and low noise. When selecting and applying this type of bearing, it is necessary to select the appropriate model and design according to the specific use conditions and requirements.

Specific types of angular contact spherical plane bearings

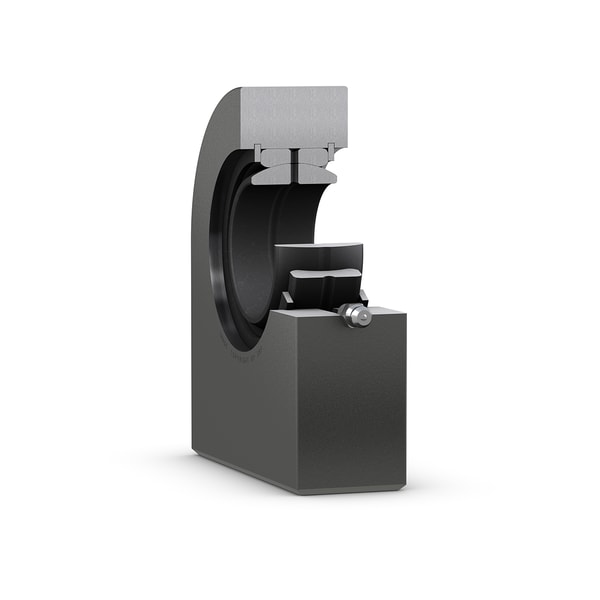

SKF Rod Ends is a special bearing assembly that is mainly used at both ends of hydraulic or pneumatic pistons to connect cylinders with related components. SKF offers Rod Ends in a variety of designs and specifications, including different thread and shank designs, making them easy to install and maintain

Structure and function SKF Rod Ends consist of an eye-shaped head and an integral shank to form a rod end seat for a spherical plain bearing. This design makes them particularly suitable for a variety of application scenarios, such as connecting components in hydraulic or pneumatic systems

SKF radial spherical plain bearings are a type of bearing specially designed to bear radial loads and combined radial and axial loads. This type of bearing has excellent misalignment compensation capabilities and can maintain good working performance even in the case of installation errors or shaft bending. SKF's radial spherical plain bearings usually use steel-on-steel or other material combinations of sliding contact surfaces to meet the needs of different working conditions

Design features and technical advantages Material selection and surface treatment: SKF's radial spherical plain bearings choose different material combinations according to specific application scenarios. For example, some models use SKF

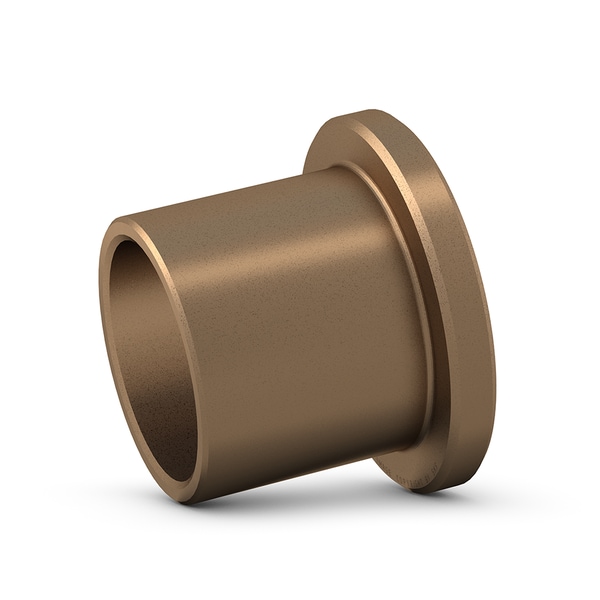

SKF's bushings, thrust washers and strips are high-quality products for a variety of applications with a wide range of applications and excellent performance.

As a world-renowned bearing brand, SKF is not only known for its high-quality rolling bearings, but also has developed into a solution-oriented supplier through continuous technological advancement and product support. SKF's products range from breakthrough application-specific products to leading design simulation tools and consulting services, as well as the industry's most advanced supply chain management technology, providing customers with greater value.

Performance characteristics and applicable scenarios SKF's plain bearings (including bushings, thrust washers and strips) The performance of SKF's plain bearings (including bushings, thrust washers and strips) mainly depends on factors such as