SKF spherical roller bearings are bearings that can withstand heavy radial and axial loads and are particularly suitable for applications with axial or axial misalignment. Their high load carrying capacity and ability to adapt to misalignment help reduce maintenance costs and extend bearing life. Features and benefits High load carrying capacity: SKF spherical roller bearings are able to withstand heavy radial and axial loads and are suitable for a wide range of high-load applications. Adaptability: These bearings can adapt to axial or axial misalignment, reducing mechanical failures and maintenance requirements caused by misalignment. Long life and low maintenance

SKF Cylindrical Roller Bearings are bearings designed to withstand heavy radial loads and high speeds and are widely used in various industrial fields. Its main features include: Design diversity: SKF cylindrical roller bearings are available in a variety of designs and sizes, including single-row and double-row full roller bearings, as well as bearings with and without cages. These designs enable them to adapt to different application requirements. Load capacity: These bearings mainly bear radial loads and have a large load capacity. The friction between the rolling element and the ring rib is small, suitable for high-speed rotation. Application scenarios: SKF cylindrical roller bearings are suitable for various industrial fields, such as construction machinery, machine tools, plastic machinery and conveying machinery. They excel in heavy-load

SKF Tapered Roller Bearings are high-performance bearings with a wide range of design options for a wide range of industrial applications. They can be customized to match specific speed, load, contamination, temperature or vibration conditions based on specific application needs. SKF Tapered Roller Bearings consist of a cup and cone assembly, where the cup is the outer ring and the cone assembly includes the inner ring, rollers and cage. This structural design is able to withstand combined loads and provide low friction in operation.

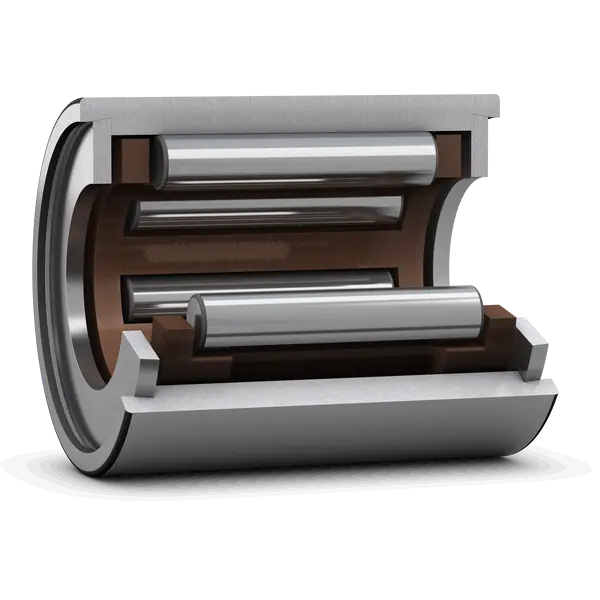

SKF Needle Roller Bearings are high-load bearings with a small diameter/length ratio, making them particularly suitable for space-constrained applications. 1. The roller length of needle roller bearings is at least four times their diameter, which makes them excellent in situations where radial space is limited. Due to their low cross-sectional height, these bearings perform well when subjected to radial loads and have a high load capacity relative to their cross-sectional height. Features and applications of SKF needle roller bearings Design features: SKF needle roller bearings usually have a deep-drawn thin-walled outer ring. This design allows the bearing to be fixed in the housing with a tight interference fit during installation, which

SKF CARB Toroidal Roller Bearings are a unique bearing design that combines the self-aligning capability of a spherical roller bearing with the unlimited axial displacement capability of a cylindrical roller bearing. This design enables CARB Toroidal Roller Bearings to maintain good operating performance in the presence of axial displacement and angular misalignment, and to withstand higher loads, thereby extending service life. Features and Applications Self-aligning capability: CARB Toroidal Roller Bearings can maintain stable operation in the presence of axial displacement and angular misalignment without increasing stress levels. Unlimited axial displacement: This bearing design allows frictionless axial movement at the non-locating end, suitable for applications that require frequent position adjustment. High load capacity: CARB Toroidal Roller Bearings can withstand high radial and axial

SKF Split Cylindrical Roller Bearings are bearings designed to withstand radial loads and feature a row of cylindrical rollers, a cylindrical inner ring and an outer ring raceway. They can be equipped with an outer ring flange (locating bearing position) or without an outer ring flange (non-locating bearing position) according to different installation requirements.

This design is particularly suitable for difficult-to-access applications, such as those that require frequent disassembly and maintenance, as its split design simplifies installation, disassembly and maintenance processes.

SKF Cylindrical Roller Thrust Bearings are bearings specially designed to withstand heavy axial loads and impact loads. They cannot withstand any radial loads, have high axial rigidity and small axial space requirements

Structural Features

SKF Cylindrical Roller Thrust Bearings consist of the following main parts:

Shaft washers and seat washers: These washers provide the support surface of the bearing.

SKF Angle Rings Roller, also known as L-Shaped Thrust Collars, are precision-engineered components designed to provide axial positioning and load support in rotating machinery. These collars feature a unique L-shaped cross-section that integrates seamlessly with cylindrical roller bearings or other bearing types, enabling precise alignment, thrust load management, and enhanced system stability. Ideal for applications requiring rigid axial guidance, SKF’s L-shaped collars are manufactured to exacting standards, ensuring reliability in high-load,

Key Features & Technical Advantages of SKF Angle Rings Roller (L-Shaped Thrust Collars)

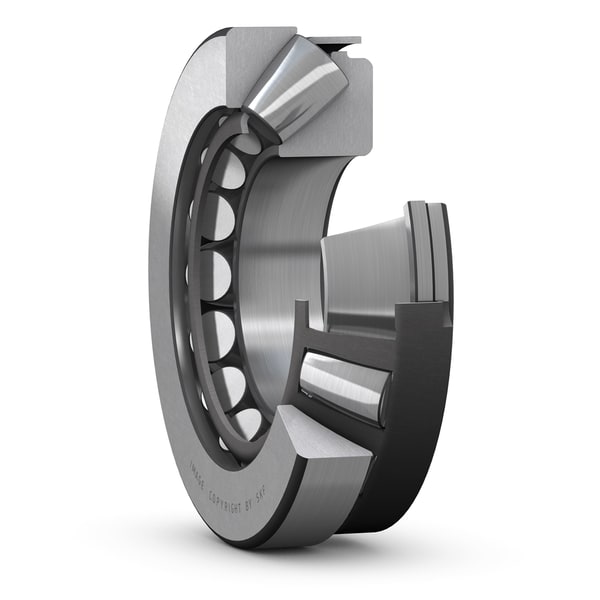

SKF spherical roller thrust bearings are a special type of bearings with many advantages and applications. Here is a detailed description:

Features and Benefits

Adaptable to various loads: Spherical roller thrust bearings are the only thrust bearings that can withstand both thrust and radial loads. This capability makes them excellent in applications that carry both thrust and radial loads.

High load capacity and stiffness: Spherical roller thrust bearings are able to provide high stiffness under high load conditions and are suitable for applications that require high load capacity and stiffness.

SKF needle roller thrust bearings are a special type of bearings that are mainly used to bear axial loads and are able to provide high rigidity and stability in a limited axial space. These bearings are usually equipped with a cage with a stable form to ensure that a large number of needle rollers are reliably retained and guided. SKF needle roller thrust bearings are designed and manufactured with a variety of factors in mind to ensure their reliability and durability in various applications. Structural features The main feature of SKF needle roller thrust bearings is their compact structure and strong rigidity. They are usually composed of needle rollers, cages, and inner and outer rings. The surfaces of the inner and outer rings can directly contact the surfaces of adjacent machine components to form raceways, thereby providing

SKF Split Spherical Roller Bearings are a special bearing design with the following key features and uses:

Design Features: SKF Split Spherical Roller Bearings feature two rows of symmetrical rollers, a common spherical outer raceway and two inner raceways that are tilted at an angle to the bearing axis. This design enables the bearings to accommodate large radial loads, while also being able to accommodate axial loads in both directions

Application Scenarios: These bearings are suitable for a variety of heavy-duty industries such as mining, mineral processing and cement production. Due to their split design, they are particularly suitable for difficult-to-access applications such as trapped bearing positions in machines, as the split design makes installation, removal and maintenance easier, reducing downtime and maintenance costs

Size Range: SKF Split Spherical Roller Bearings are available in two size ranges: one with a bore diameter from 140 to 200 mm and the other with a bore diameter from 240 to 450 mm. For other sizes, please contact SKF for more information.

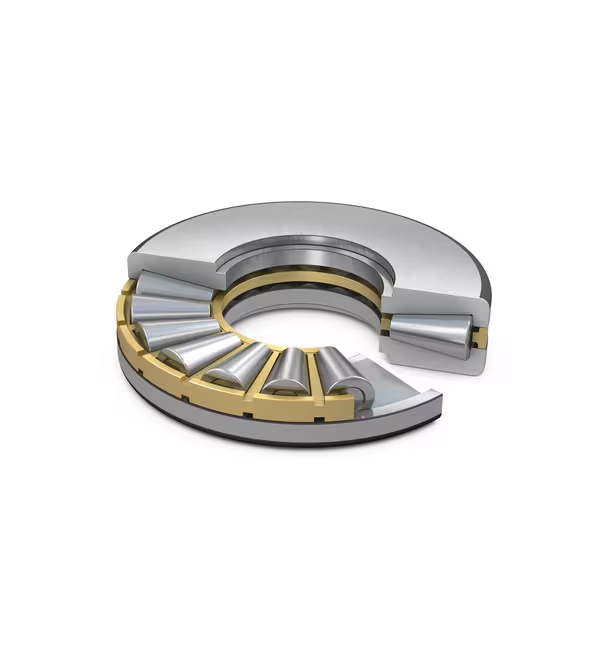

SKF Tapered Roller Thrust Bearings are high-performance bearings engineered to manage heavy axial loads and moderate radial loads in demanding industrial applications. Featuring tapered rollers and matching raceways, these bearings excel in transmitting unidirectional axial forces while accommodating combined load scenarios. Their precision design ensures optimal load distribution, reduced friction, and extended service life, making them indispensable in industries such as automotive, heavy machinery, aerospace, and energy. SKF’s expertise in material science and manufacturing guarantees reliability, even in harsh operating conditions.

Key Features & Benefits of SKF Tapered Roller Thrust Bearings