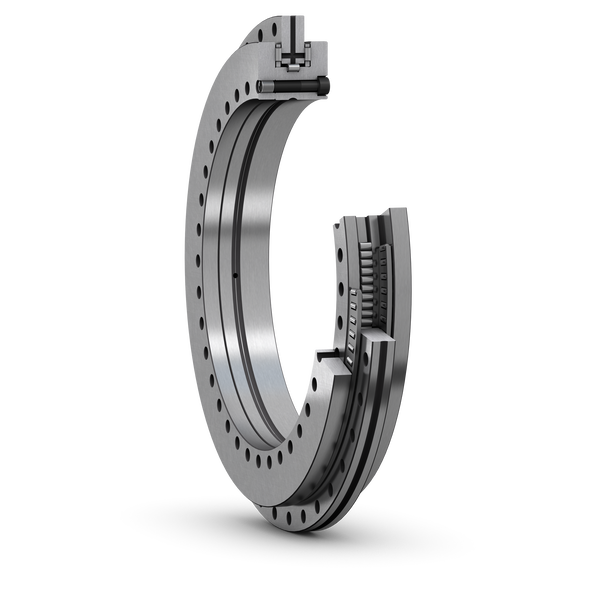

SKF Super-Precision axial-radial roller bearings are bearings designed for high-precision applications with the following key features:

High precision and low friction: These bearings offer extremely low friction and excellent precision and are suitable for a variety of high-precision applications such as machine tool spindles and other precision equipment

High load capacity: SKF's super-precision angular contact ball bearings are designed for high-load applications and feature high load capacity, high stiffness, long service life and low heat generation

SKF Super-Precision Angular Contact Thrust Bearings are high-precision bearings that are particularly suitable for applications that require high precision and high speed. These bearings have the following features and benefits:

High precision and low friction: SKF Super-Precision Angular Contact Thrust Bearings offer extremely low friction and excellent accuracy, and are able to maintain stable performance under high loads, making them suitable for a variety of high-precision applications such as machine tools and automotive engines

High load capacity and high speed: These bearings have high axial rigidity and high axial load capacity, and are able to withstand high speeds and rapid accelerations, making them suitable for screw driving applications that require fast, efficient and precise positioning

SKF Super-Precision Cylindrical Roller Bearings are engineered for ultra-high radial load capacity, precision, and rigidity in demanding applications requiring micron-level accuracy. Designed for machine tool spindles, aerospace systems, and high-speed industrial machinery, these bearings minimize friction and heat generation while delivering exceptional rotational stability.

SKF Super Precision Cylindrical Roller Bearings have the following characteristics:

High speed capability: These bearings are designed to operate in high-speed environments and can withstand high speeds without producing excessive noise, vibration, or heat

SKF Super-Precision Angular Contact ball Bearings are engineered for ultra-high-speed, high-rigidity, and extreme accuracy applications. These bearings support combined radial and axial loads while maintaining micron-level running accuracy, making them ideal for machine tool spindles, robotics, aerospace systems, and medical equipment.