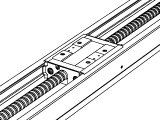

THK's LM Guide Actuator SKR20 series represents a sophisticated integration of linear motion technology, combining a Caged Ball LM Guide Actuator with a motor wrap, long nut, and block assemblies (Types A and B) with protective covers. This design centers on the caged ball retainer system within the LM guide, which precisely positions steel balls in a non-recirculating pattern to minimize friction, reduce heat generation, and eliminate ball-to-ball contact. The actuator incorporates a precision-ground shaft with a long nut for efficient force transmission, while the block—available in standard (Type A) or flange-mounted (Type B) configurations—provides robust support and alignment. Protective covers shield critical components from contaminants, enhancing durability in harsh environments. The motor wrap interface allows seamless coupling with servo or stepper motors, enabling programmable positioning and velocity control.

Key technical features include the caged ball retainer, which ensures smooth motion by maintaining consistent ball spacing and reducing vibration. The SKR20 actuator offers high rigidity due to its optimized block design and four-row ball contact structure, capable of handling moment loads and off-center forces. Preload adjustments are available to minimize deflection under load, while the long nut design enhances torque transmission efficiency and backlash control. Lubrication ports facilitate maintenance, and the covers protect against dust, chips, and moisture, complying with IP ratings for industrial use. Materials such as hardened steel for raceways and aluminum alloy for blocks ensure longevity and corrosion resistance.

Performance advantages stem from THK's engineering focus on precision and reliability. The caged ball system reduces noise levels by up to 10 dB compared to conventional designs, while lowering friction coefficients by approximately 30%, resulting in higher efficiency and extended service life. The actuator achieves positioning accuracy within ±0.005 mm/m and supports speeds up to 2 m/s with minimal maintenance intervals. Its compact form factor saves space in machinery layouts, and the modular design simplifies installation and replacement. Energy efficiency is improved through reduced power consumption, and the compatibility with various motor types allows customization for specific torque and speed requirements.

Typical applications span industries requiring precise linear motion. In industrial machinery, the SKR20 series is deployed in CNC machining centers for tool changers and axis drives, in semiconductor manufacturing equipment for wafer handling robots, and in packaging systems for repetitive pick-and-place operations. Automotive production lines utilize these actuators in welding gun positioners, assembly robots, and test rigs for component durability checks. Precision equipment applications include medical devices like MRI scanner beds, optical alignment systems in lithography, and coordinate measuring machines (CMMs) for metrology. The series' resilience to contaminants and vibrations makes it suitable for food processing conveyors and automotive paint shops, where environmental challenges are prevalent. By delivering high load capacity, smooth operation, and configurable options, THK's SKR20 LM Guide Actuator series addresses the demands of modern automation with reliability and precision.

THK's LM Guide Actuator SKR20 series represents a sophisticated integration of linear motion technology, combining the precision of a Caged Ball LM Guide with the driven functionality of an actuator system. This design incorporates a motor wrap and long nut block configuration, available in both A and B SERIES variants, engineered to deliver exceptional performance in demanding industrial applications. The core of the SKR20 actuator lies in its caged ball retainer system within the LM guide, which effectively prevents ball-to-ball contact, reducing friction, heat generation, and wear. This results in smoother motion, enhanced durability, and consistent precision over extended operational periods.

Key technical features include the preloaded ball recirculation system that eliminates backlash, ensuring high positional accuracy and rigidity. The integrated long nut block provides efficient force transmission from the motor, while the compact motor wrap design allows for seamless integration with various servo or stepper motors. The SKR20 is constructed from high-grade steel with precision grinding and hardening processes, offering excellent resistance to deformation under load. Its sealing systems are designed to protect against contaminants like dust and chips, making it suitable for harsh environments. The A and B SERIES distinctions typically relate to specific dimensional configurations, load capacities, or mounting options, allowing engineers to select the optimal model for their spatial and performance requirements.

Performance advantages are substantial, starting with significantly reduced maintenance needs due to the caged ball technology that minimizes lubricant consumption and extends relubrication intervals. The actuator achieves high-speed capabilities with low noise levels, contributing to quieter and more efficient machinery operation. Its high rigidity and load capacity—supporting moments in all directions—enable it to handle complex multi-axis movements without sacrificing precision. The efficiency of the ball screw mechanism within the actuator translates to improved energy utilization, reducing overall system power consumption while maintaining thrust force consistency.

Typical applications span across multiple high-precision industries. In industrial automation, the SKR20 is deployed in CNC machining centers for tool changing mechanisms, precision assembly robots for electronic component placement, and semiconductor manufacturing equipment where micron-level accuracy is critical. The automotive sector utilizes these actuators in automated welding systems, painting robots, and engine assembly lines where repeatability and durability under high-cycle conditions are essential. In precision equipment, they are found in medical device manufacturing systems, optical alignment apparatuses, and coordinate measuring machines that demand smooth, vibration-free linear motion. The robust design also supports use in packaging machinery, material handling systems, and aerospace testing equipment, demonstrating its versatility in combining high load capacity with precise positional control for optimized operational reliability.