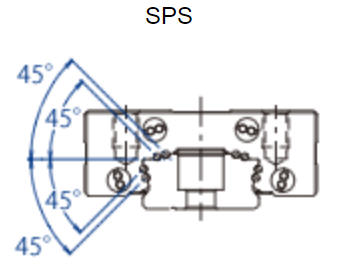

THK's LM Guide Caged Ball LM Guide Models SPRSPS SPS SERIES represent a significant advancement in linear motion technology, engineered specifically to address the demanding requirements of high-speed, high-precision, and high-load applications. This series incorporates a unique caged ball design where the recirculating steel balls are separated and retained by a precision-engineered polymer cage. This fundamental design element eliminates ball-to-ball contact, drastically reducing friction, heat generation, and torque fluctuation. The result is an exceptionally smooth and quiet operation, even at extreme velocities, setting a new benchmark for performance and reliability in linear guidance systems.

The technical features of the SPRSPS SPS SERIES are meticulously crafted for superior performance. The incorporation of the caged ball mechanism is its cornerstone, which not only minimizes friction but also prevents the scattering of balls, allowing for cleaner operation and easier handling during installation and maintenance. The guide rails and blocks are manufactured from high-grade steel, subjected to THK's proprietary heat treatment processes to achieve an optimal balance of surface hardness for wear resistance and a tough core material for impact resistance. Precision grinding ensures exceptional straightness and flatness, guaranteeing consistent accuracy over the entire travel length. These guides are available in various accuracy classes and preload levels, enabling engineers to precisely match the component to the specific stiffness and precision demands of their application.

The performance advantages derived from this design are substantial. The reduction in friction directly translates to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and drives. The stable, low-friction operation allows for significantly higher maximum speeds and accelerations, which is critical for reducing cycle times in automated machinery. Furthermore, the excellent motion smoothness minimizes vibration and noise, contributing to higher quality surface finishes in machining applications and a better working environment. The durability of the components ensures a long service life with minimal maintenance, even in harsh conditions involving chips, dust, or minimal lubrication, leading to reduced total cost of ownership.

Typical applications for the THK SPRSPS SPS SERIES are found wherever high dynamic performance and precision are paramount. In industrial machinery, they are extensively used in the high-speed axes of CNC machining centers, electric discharge machines (EDMs), and precision grinding machines, where they ensure contouring accuracy and superior surface finish. Within automotive manufacturing systems, these guides are integral to high-speed robotic arms for assembly and welding, precision transfer lines, and automated inspection equipment. In the realm of precision equipment, they provide the critical motion foundation for semiconductor manufacturing apparatus, such as wafer steppers and probe handlers, and are equally vital in precision measuring instruments and medical automation devices, where smooth, vibration-free motion is non-negotiable for achieving micron-level accuracy.

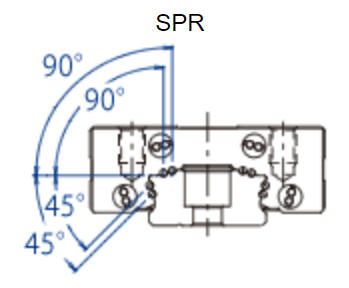

THK's LM Guide Caged Ball LM Guide Models SPRSPS and SPR SERIES represent a significant advancement in linear motion technology, specifically engineered to address the demanding requirements of high-speed, high-load, and high-precision applications. These guides incorporate a unique caged ball design where precision steel balls are retained and separated by a polymer cage, effectively eliminating metal-to-metal contact between the balls during operation. This fundamental design principle is the cornerstone of their superior performance and reliability.

The technical features of the SPRSPS and SPR SERIES are meticulously crafted for optimal performance. The incorporation of the ball cage drastically reduces friction and heat generation, which are common culprits of premature wear in conventional linear guides. This design also prevents torque fluctuation and ensures exceptionally smooth, consistent motion. The series is available in various accuracy grades and preload levels, allowing for precise customization to match specific application stiffness and precision demands. Components are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment processes to achieve a high surface hardness, resulting in exceptional durability and a long operational life. The compact and rigid structure of the guide blocks and rails provides high resistance to moment loads, ensuring stability under complex force conditions.

The performance advantages derived from these features are substantial. The most notable benefit is a dramatic extension of service life, often several times that of standard non-caged ball LM guides, by preventing ball-to-ball abrasion. The reduction in friction directly translates to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and drives. Furthermore, the stable motion characteristics allow for higher maximum speeds and accelerations while maintaining positioning accuracy, which is critical for improving cycle times in automated machinery. The consistent performance also leads to reduced maintenance intervals and lower total cost of ownership over the system's lifespan.

These attributes make the THK SPRSPS and SPR SERIES ideal for a wide range of demanding applications across multiple industries. In industrial automation, they are indispensable in high-speed pick-and-place robots, precision assembly machines, and automated inspection systems where speed, accuracy, and reliability are paramount. Within the automotive manufacturing sector, these guides are deployed in high-duty welding robots, precision laser cutting cells, and high-speed transfer lines that operate continuously under significant loads. For precision equipment, such as semiconductor manufacturing apparatus, CNC machining centers, and medical diagnostic devices, the series' smooth motion, minimal vibration, and high positional accuracy are essential for achieving micron-level tolerances and repeatability. The THK Caged Ball LM Guide SPR SERIES thus stands as a robust, high-performance solution for engineers seeking to push the boundaries of speed, precision, and longevity in linear motion systems.