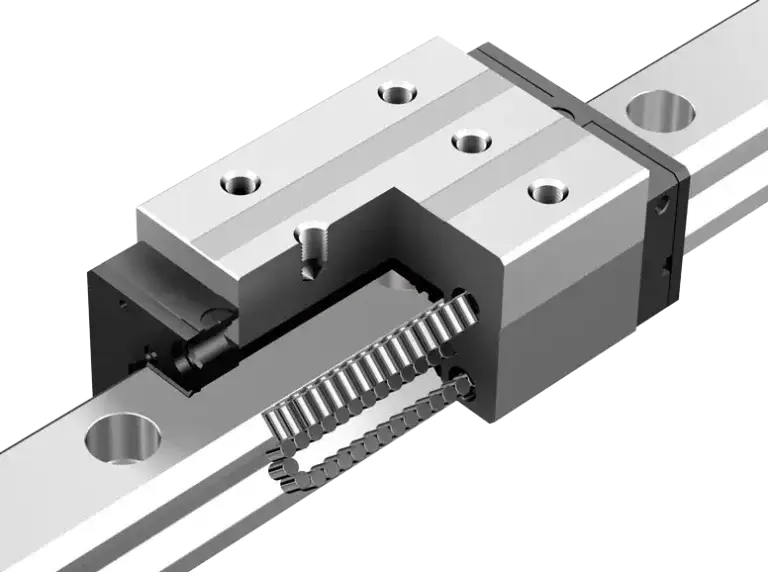

THK's SPRSPS Series represents a specialized evolution in linear motion technology, featuring a Caged Ball LM Guide design that fundamentally enhances performance and reliability in demanding applications. This model incorporates a unique retainer, or cage, that systematically separates the recirculating balls within the guide block. This design is a direct response to the limitations of conventional linear guides, where balls can contact each other during recirculation, leading to increased friction, heat generation, and noise. By fully encapsulating each ball, the SPRSPS model ensures smooth, consistent rolling motion, drastically reducing rotational torque fluctuations and minimizing wear on critical components.

The technical features of the SPRSPS are engineered for superior operational integrity. The caged ball structure eliminates ball-to-ball contact, which is the primary source of abrasive wear and grease degradation in standard designs. This results in a dramatic extension of service life and maintenance intervals. The guide block and rail are manufactured from high-grade steel, subjected to THK's proprietary heat treatment processes to achieve exceptional surface hardness and core toughness, providing outstanding resistance to denting and fatigue under high load conditions. Precision grinding of the raceway profiles ensures optimal ball contact, distributing loads evenly and enhancing rigidity. Furthermore, the inclusion of high-performance seals effectively shields the internal recirculating system from contaminants like dust, chips, and moisture, making the unit exceptionally durable in harsh environments.

Performance advantages are immediately evident in operational efficiency and longevity. The significant reduction in friction directly translates to lower driving force requirements, enabling the use of smaller, more energy-efficient motors and drives. The stable, low-torque rotation allows for higher, more consistent speeds and accelerations, which is critical for improving cycle times in automated systems. The inherent cleanliness of the caged design prevents metal-to-metal contact and the associated generation of particulate debris, a vital characteristic for cleanroom applications or situations where product contamination is a concern. This combination of low friction, high speed capability, and minimal maintenance demands results in a lower total cost of ownership over the system's extended lifespan.

Typical applications for the THK SPRSPS Caged Ball LM Guide are found in sectors where precision, speed, and reliability are non-negotiable. In industrial machinery, it is ideally suited for high-speed automated assembly lines, precision CNC machining centers performing rapid tool changes, and industrial robots requiring smooth, high-acceleration motion. Within the automotive industry, these guides are deployed in high-cycle testing equipment, precision welding robots, and automated painting systems where consistent, jerk-free movement is essential for quality. For precision equipment, the SPRSPS is a critical component in semiconductor manufacturing apparatus, including wafer steppers and inspection machines, as well as in medical device assembly systems and precision measuring instruments, where its cleanliness and smooth motion guarantee the highest levels of accuracy and repeatability.

THK's LM Guide (full ball type) represents a pinnacle of linear motion technology, engineered to deliver exceptional precision, rigidity, and longevity in demanding applications. This system features a unique recirculating ball design where the load-bearing balls make full contact with the raceways, distributing loads evenly across the entire ball surface. The guide comprises a rail and a sliding block (carriage) containing precisely engineered ball circuits. These circuits allow for infinite travel lengths by continuously recirculating the balls through a compact, efficient path within the block. Manufactured from high-carbon chromium bearing steel, the components undergo rigorous heat treatment and grinding processes to achieve superior hardness, dimensional accuracy, and surface finish, ensuring consistent performance under high loads and repetitive motion.

Key technical features include the full ball contact design, which maximizes load capacity and moment rigidity. The optimized ball groove profile ensures smooth, low-friction motion with minimal rolling resistance. Advanced sealing systems, often incorporating multi-layer contact seals and optional scrapers, effectively exclude contaminants like dust, chips, and moisture while retaining lubrication, significantly extending service life even in harsh environments. Many models offer preload options, allowing for the elimination of internal clearance to achieve zero backlash, which is critical for applications requiring high positional accuracy and repeatability. The compact, space-saving design of the sliding block facilitates easy integration into machinery with limited installation space.

The performance advantages of the THK LM Guide (full ball type) are substantial. It exhibits exceptionally high load capacities in all directions—radial, reverse radial, and lateral—as well as high resistance to moment loads (pitch, yaw, and roll). This results in unparalleled stability and vibration damping, crucial for maintaining precision. The low friction coefficient contributes to high mechanical efficiency, reducing driving force requirements and energy consumption. Its durability and maintenance-free operation, thanks to the effective sealing and long-term lubrication, minimize downtime and total cost of ownership. The system operates smoothly at high speeds with low noise levels, making it suitable for modern, high-throughput automation.

Typical applications span across critical sectors in industrial machinery, automotive systems, and precision equipment. In industrial automation, these guides are indispensable in CNC machining centers for tool changer arms, spindle drives, and feed axes; semiconductor manufacturing equipment for wafer handling robots and steppers; and precision assembly machines for pick-and-place units. The automotive industry utilizes them in robotic welding arms, painting robots, and precision test stands for component validation. Within precision equipment, they are found in medical devices like MRI and CT scanner beds, optical positioning stages, and coordinate measuring machines (CMMs), where smooth, accurate, and reliable linear motion is non-negotiable for achieving stringent performance standards.

THK's LM Guide (Full Roller Type) represents a significant evolution in linear motion technology, engineered to deliver exceptional rigidity, high load capacity, and smooth, precise movement under the most demanding industrial conditions. This system utilizes cylindrical rollers as the rolling elements within the guide mechanism, a design choice that fundamentally enhances its performance characteristics over traditional ball-based systems. The full roller configuration ensures a larger contact area between the rollers and the raceways, distributing loads more effectively and enabling the guide to withstand substantial forces from all directions—radial, reverse-radial, and lateral.

Key technical features define its superior capability. The rollers are meticulously arranged in a full-complement structure, eliminating the need for a retainer and maximizing the number of load-bearing elements within the limited space of the block. This design achieves a remarkably high load rating and stiffness, significantly reducing elastic deformation under stress. The LM Guide (Full Roller Type) incorporates precisely ground raceways and rollers, coupled with a optimized crowning profile at the roller ends. This critical engineering detail mitigates stress concentration at the edges, ensuring smooth roller circulation and maintaining consistent, low-friction motion throughout the entire stroke. Many models also integrate seals and wipers to effectively shield the critical rolling elements from contaminants like dust, chips, and moisture, thereby ensuring long-term operational reliability and reducing maintenance intervals.

The performance advantages are substantial and directly address the needs of heavy-duty and high-precision applications. The immense rigidity translates into minimal deflection during operation, which is paramount for maintaining accuracy in machining and positioning tasks. Its high load capacity allows for the design of more compact machinery, as a single Full Roller Type LM Guide can often handle loads that would otherwise require larger or multiple ball-type guides. The system exhibits excellent damping characteristics, absorbing vibrations and contributing to smoother operation, reduced noise levels, and improved surface finish in machining processes. Furthermore, the efficient roller-to-raceway contact results in a lower coefficient of friction, which can contribute to reduced power consumption for driving mechanisms.

These attributes make the THK LM Guide (Full Roller Type) an indispensable component across a wide spectrum of industries. In industrial machinery, it is the preferred solution for heavy-duty machining centers, where it provides the stable foundation for spindle heads and columns subjected to intense cutting forces. It is equally critical in high-precision grinding machines and electrical discharge machining (EDM) equipment, where its rigidity ensures micron-level accuracy. Within the automotive sector, these guides are deployed in robust robotic welding and assembly arms, transfer lines handling heavy engine blocks, and high-speed pick-and-place systems. In the realm of precision equipment, they facilitate exacting movements in semiconductor manufacturing apparatus, such as steppers and wafer handlers, and in precision measuring instruments, where any play or deflection would compromise the integrity of the measurement data.

THK's LM Guide Caged Roller LM Guide represents a significant advancement in linear motion technology, engineered to deliver exceptional rigidity, precision, and longevity in demanding applications. This system incorporates a unique caged roller design where precision rollers are retained and guided by a cage, preventing direct contact between adjacent rollers. This configuration eliminates metal-to-metal friction among the rolling elements, substantially reducing operational torque, heat generation, and wear. The rollers themselves are meticulously ground to exacting tolerances, ensuring smooth, consistent motion along the hardened steel raceways. Key technical features include four-way equal load capacity, allowing the guide to handle radial, reverse radial, and lateral loads simultaneously with high rigidity. The optimized contact geometry between the rollers and raceways distributes stress evenly, enhancing load-carrying capability and resistance to deformation under heavy or moment loads. Sealing systems are comprehensively integrated, featuring multi-layer contact seals and optional scrapers to exclude contaminants like dust, chips, and moisture, which is critical for maintaining performance in harsh environments.

Performance advantages are substantial and multifaceted. The caged roller design drastically reduces friction torque compared to standard ball-based LM guides, enabling higher speeds and accelerations with lower drive force requirements, which translates into energy savings and reduced motor sizing. Vibration and noise levels are significantly minimized, contributing to smoother operation and improved positional accuracy. This makes the system exceptionally suitable for high-precision applications where minimal vibration is paramount. The inherent design also allows for more excellent preload options, providing superior stiffness and minimal deflection under load, which is crucial for machining operations and precision assembly. Durability is another hallmark; by preventing roller-to-roller contact and skidding, the cage reduces wear and the risk of brinelling, leading to a dramatically extended service life even under challenging conditions involving shock loads or poor lubrication.

Typical applications leverage these robust characteristics across various demanding sectors. In industrial machinery, these guides are indispensable in high-load machine tools, such as machining centers, grinding machines, and milling machines, where they provide the stability and precision necessary for tight-tolerance manufacturing. They are also found in injection molding machines, supporting heavy platens with minimal deflection. Within automotive manufacturing systems, they are deployed in high-duty robotic welding arms, precision transfer lines, and automated assembly systems that require reliable, high-speed, and high-accuracy motion under constant, heavy loads. For precision equipment, the Caged Roller LM Guide is ideal for semiconductor manufacturing apparatus, including wafer steppers and inspection equipment, where ultra-smooth, low-vibration motion is non-negotiable. Its robustness also makes it a preferred choice in aerospace testing fixtures and large-scale coordinate measuring machines (CMMs), where long-term accuracy and reliability under significant stress are critical operational requirements.

THK's Caged Ball LM Guide represents a significant evolution in linear motion technology, addressing fundamental limitations of conventional ball-based guide systems. At its core, this system retains the recirculating ball principle but introduces a revolutionary polymer cage that fully encapsulates each ball bearing within its own individual compartment. This cage structure fundamentally transforms the operational dynamics of the guide mechanism, eliminating direct ball-to-ball contact that traditionally causes friction, heat generation, and lubricant starvation in high-speed applications. The result is a linear guide system offering exceptionally smooth motion with minimal resistance, even under demanding operational conditions.

The technical features of the Caged Ball LM Guide are engineered for superior performance and longevity. The precision-engineered cage maintains perfect ball spacing and alignment, ensuring consistent load distribution across all contact points. This design drastically reduces torque variation and provides exceptional running accuracy, making it ideal for applications requiring precise positional control. The system's ability to operate effectively with minimal lubrication is another critical advantage, as the cage prevents lubricant from being scraped away by adjacent balls. This not only extends maintenance intervals but also makes the system suitable for clean environments where lubricant contamination is a concern. Furthermore, the cage acts as a debris barrier, protecting the precision ball grooves from particulate contamination that could otherwise lead to premature wear and failure.

Performance advantages translate directly into operational benefits across various industries. In industrial automation, these guides provide the high-speed, low-vibration motion essential for pick-and-place robots, CNC tool changers, and high-throughput assembly lines where cycle time and positioning repeatability are paramount. The automotive manufacturing sector utilizes these guides in precision welding systems, laser cutting equipment, and automated inspection stations, where their resistance to shock loads and consistent performance under high-duty cycles ensure uninterrupted production. For precision equipment, the Caged Ball LM Guide's minimal torque variation and smooth motion characteristics make it indispensable in semiconductor manufacturing equipment, medical diagnostic devices, and coordinate measuring machines where nanometer-level precision and vibration-free operation are non-negotiable requirements. The combination of high-speed capability, extended service life, and reduced maintenance needs positions THK's Caged Ball LM Guide as a superior solution for modern linear motion challenges across multiple demanding industrial sectors.