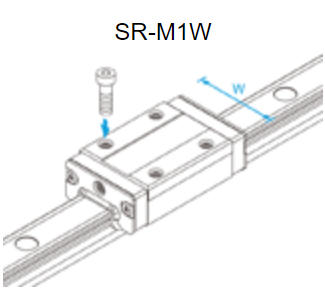

THK's LM Guide LM Guide (full ball type) High Temperature SR M1W SERIES represents a significant advancement in linear motion technology, engineered specifically for environments where elevated temperatures and demanding operational conditions are the norm. This series incorporates a full-ball type design, where the recirculating balls maintain continuous contact along the entire raceway, ensuring uniform load distribution and enhanced rigidity. The SR M1W is constructed from heat-resistant materials, including special steel for the rails and blocks, and high-temperature-resistant resins and seals, allowing it to operate reliably in temperatures up to 150°C. Key technical features include an optimized ball groove profile that minimizes friction and wear, even under high loads, and advanced sealing systems that prevent the ingress of contaminants like dust, chips, and moisture, which is critical in harsh industrial settings. The series also boasts a compact design, facilitating easy integration into space-constrained machinery without sacrificing performance.

Performance advantages of the SR M1W SERIES are substantial, starting with its exceptional durability and longevity under thermal stress. The full-ball configuration reduces vibration and noise, contributing to smoother motion and higher precision in positioning tasks. It offers low friction coefficients, which translate to reduced energy consumption and less heat generation during operation, further supporting its suitability for high-temperature applications. Maintenance requirements are minimized due to the robust sealing and corrosion-resistant treatments, leading to lower total cost of ownership over the system's lifecycle. Additionally, the LM Guide provides high load capacity in all directions—radial, reverse-radial, and lateral—making it versatile for complex motion profiles. Its ability to maintain accuracy and stability, even with thermal expansion, ensures consistent performance in precision-driven processes.

Typical applications span various industries where reliability in heated or aggressive environments is paramount. In industrial machinery, the SR M1W SERIES is ideal for furnace door mechanisms, heat treatment equipment, and welding robots, where components are exposed to sustained high temperatures and particulate debris. Within automotive systems, it finds use in engine test benches, exhaust system handling robots, and paint-drying conveyor systems, where thermal resilience and contamination resistance are essential for uptime and safety. In precision equipment, this series supports semiconductor manufacturing tools, such as wafer handling arms in high-temperature chambers, and medical device autoclaves, where sterile, high-heat conditions demand unwavering accuracy. By combining thermal endurance with low-maintenance design, the THK SR M1W SERIES enables enhanced efficiency, reduced downtime, and improved product quality across these critical sectors, solidifying its role as a dependable solution for challenging linear motion needs.

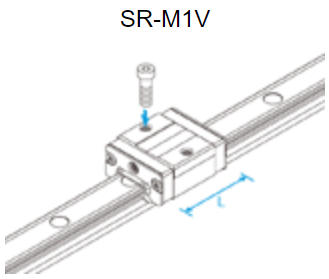

THK's LM Guide LM Guide (full ball type) High Temperature SR M1V SERIES represents a specialized advancement in linear motion technology, engineered to deliver exceptional performance and reliability in demanding high-temperature environments. This series incorporates a full ball-type design where recirculating balls maintain continuous contact between the rail and block, ensuring smooth, precise linear movement even under extreme thermal conditions. The SR M1V is constructed from heat-resistant materials, including specially treated steel components and high-temperature lubricants, allowing it to operate reliably at temperatures up to 150°C. Its robust sealing system effectively prevents the ingress of contaminants like dust, chips, and moisture, while retaining lubrication to extend service life in harsh industrial settings.

Key technical features of the SR M1V SERIES include its optimized ball groove geometry, which minimizes friction and distributes loads evenly across the rolling elements. This design enhances rigidity and load capacity, supporting high moment loads and dynamic forces without compromising accuracy. The guide incorporates a compact, low-profile structure, making it suitable for applications with space constraints. Preloaded ball configurations are available to eliminate backlash, ensuring precise positioning and repeatability. Additionally, the series offers corrosion-resistant options, further broadening its applicability in aggressive environments.

Performance advantages are evident in its ability to maintain smooth motion and high positional accuracy under thermal stress, reducing wear and maintenance requirements. The full ball-type recirculation system provides high-speed capability and low noise operation, contributing to energy efficiency and improved machine productivity. Its durability in high-temperature conditions translates to longer intervals between replacements and reduced downtime, offering significant cost savings over the system's lifecycle.

Typical applications for the SR M1V SERIES span various industries where high temperatures and precision are critical. In industrial machinery, it is used in injection molding machines, die-casting equipment, and furnace door mechanisms, where thermal resistance ensures consistent operation. Automotive systems benefit from its integration into engine testing rigs, welding robots, and paint shop conveyors, where it withstands heat from processes and ambient conditions. Precision equipment applications include semiconductor manufacturing tools, LCD panel handlers, and medical device assemblers, where its accuracy and thermal stability support fine-tuned processes. By combining high-temperature resilience with THK's renowned precision, the SR M1V SERIES enables enhanced performance and reliability in the most challenging operational scenarios.

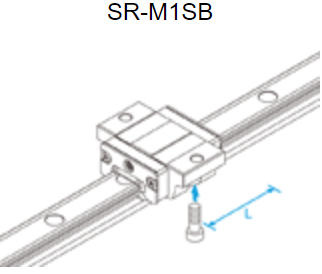

THK's LM Guide LM Guide (full ball type) High Temperature SR M1SB SERIES represents a specialized advancement in linear motion technology, engineered to deliver uncompromised performance in demanding high-temperature environments. This series incorporates a full-ball type LM guide structure, where the rolling elements are precision-ground balls that circulate continuously between the rail and block. The defining characteristic of the SR M1SB is its exceptional thermal stability, achieved through a meticulously selected heat-resistant steel for the critical components—the rail, block, and balls. This material composition is specifically treated to resist softening, deformation, and loss of hardness when subjected to sustained elevated temperatures, typically in a range up to 150°C and, with specialized lubrication, even higher for intermittent duty.

The technical features of this series are tailored for thermal resilience and sustained accuracy. The full-ball contact design provides high rigidity and load capacity in all directions—radial, reverse-radial, and lateral. The ball grooves are precision-machined with a Gothic arch profile, optimizing contact stress distribution and ensuring smooth, low-friction motion. To combat the primary challenge of high-temperature operation, the series utilizes a specialized high-temperature grease, packed within a high-performance seal system. These seals, often made from heat-resistant rubber or advanced polymers, are multi-layered to effectively retain lubrication and aggressively exclude contaminants like dust and scale, which are more prevalent in hot industrial settings. This combination prevents grease breakdown, premature wear, and seizure.

The performance advantages are significant for operations where heat is a byproduct of the process. The SR M1SB SERIES maintains positional accuracy and preload over extended periods, minimizing thermal drift that can compromise machining or assembly precision. Its high-temperature resilience directly translates to reduced maintenance intervals, lower lifecycle costs, and enhanced machine uptime, as the guideway does not require frequent replacement due to heat-induced degradation. The smooth, stable motion also contributes to lower noise and vibration levels, even under heavy loads in hot conditions.

Typical applications are found in industries where machinery operates with inherent heat generation. In industrial machinery, these guides are indispensable for the sliding tables of injection molding machines, where they are positioned near the heated barrel, and in die-casting machines, handling the intense heat from molten metal processes. Within automotive manufacturing systems, they are deployed in welding robots and paint-drying oven conveyors, where components must reliably function despite radiant heat. In the realm of precision equipment, the SR M1SB SERIES is integrated into semiconductor manufacturing apparatus, such as wafer handling robots in high-temperature process chambers, and in the precise stages of laser processing machines used for cutting or welding, where environmental heat would render standard linear guides ineffective.

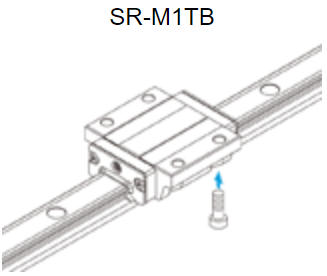

The THK LM Guide LM Guide (full ball type) High Temperature SR M1TB SERIES represents a significant advancement in linear motion technology, engineered specifically to maintain exceptional performance under extreme thermal conditions. This series incorporates a full-ball type design where the load-bearing balls circulate in a complete loop, ensuring uniform stress distribution and enhanced load capacity. The SR M1TB is constructed from heat-resistant materials, including specially formulated stainless steel for the rails and blocks, and high-temperature stable polymers for seals and retainers. This allows continuous operation in environments ranging from 150°C to 250°C, with short-term tolerance even higher. The guide features THK's proprietary Caged Ball technology, which minimizes friction and heat generation by preventing direct ball-to-ball contact, thereby reducing wear and extending service life. Pre-loaded ball grooves provide high rigidity and precision, minimizing deflection under load for consistent, repeatable motion.

Performance advantages of the SR M1TB SERIES are substantial in demanding applications. Its high-temperature resilience ensures minimal thermal expansion, preserving accuracy and preventing binding or seizure in heated zones. The full-ball design offers superior load capacity in all directions—radial, reverse-radial, and lateral—making it robust against complex force vectors. Smooth, low-friction motion results in higher efficiency, reducing the power required for actuation and lowering operational costs. The caged ball construction not only extends lifespan by reducing wear but also maintains quieter operation by eliminating ball-to-ball collisions. Enhanced sealing systems protect against contaminants like dust, chips, and splashing liquids, which is critical in harsh industrial or automotive settings. These features collectively contribute to reduced maintenance intervals, higher machine uptime, and improved overall system reliability.

Typical applications for the SR M1TB SERIES span industries where high temperatures and precision are paramount. In industrial machinery, it is ideal for furnace door mechanisms, heat treatment equipment, injection molding machines, and packaging systems operating in heated environments. The automotive sector utilizes these guides in engine test stands, brake system assembly lines, and welding robots exposed to elevated temperatures. In precision equipment, they are deployed in semiconductor manufacturing tools, such as wafer handling and lithography systems, where thermal stability is crucial for micron-level accuracy. Additionally, food processing machinery with high-temperature sterilization stages and glass manufacturing equipment benefit from the series' durability and heat resistance. By integrating the SR M1TB SERIES, engineers can achieve reliable, long-lasting linear motion in scenarios where standard guides would fail, ensuring optimal performance in the most challenging operational conditions.

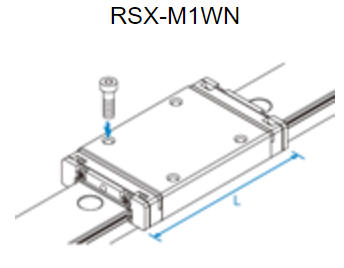

THK's LM Guide RSX M1WN SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature environments where conventional guides would falter. This full ball type LM Guide incorporates a robust, heat-resistant design that maintains precision and reliability even when exposed to temperatures up to 150°C continuously, with peak tolerance reaching 200°C. The core of its construction lies in the use of specially formulated heat-resistant resins for the end seals and LM block, alongside stainless steel end plates, ensuring structural integrity and corrosion resistance under thermal stress. The ball grooves are precision-ground with a Gothic arch profile, optimizing contact points to distribute loads evenly and minimize friction, while the full ball recirculation system ensures smooth, uninterrupted motion by maintaining constant ball contact within the load-bearing raceways.

Key technical features include a compact LM block design that saves space without compromising load capacity, thanks to its high rigidity and four-row circular arc groove configuration. The inclusion of high-performance seals—such as the steel scrapers and specialized grease seals—effectively prevents contaminants like dust, chips, and moisture from infiltrating the ball recirculation paths, even in harsh conditions. This is complemented by a pre-load adjustment mechanism that allows for fine-tuning to eliminate backlash, enhancing positional accuracy and stability during operation. The RSX M1WN SERIES also supports high-speed applications, with its optimized recirculation system reducing noise and vibration, which is critical for maintaining smooth motion profiles in dynamic setups.

Performance advantages of this series are evident in its ability to deliver consistent precision and longevity under thermal duress. The heat-resistant components resist deformation and degradation, extending service life and reducing maintenance intervals in demanding settings. Its high load capacity—supporting moments and loads in all directions—makes it suitable for applications involving heavy or uneven forces, while the low friction coefficient contributes to energy efficiency by minimizing power consumption. Additionally, the guide's corrosion-resistant properties, derived from stainless steel elements, make it ideal for environments with exposure to coolants, chemicals, or humidity, further broadening its applicability.

Typical applications span industries where high temperatures and precision are paramount. In industrial machinery, the RSX M1WN SERIES is deployed in injection molding machines, where it guides ejector units and moving platens exposed to heat from molten plastics, ensuring repeatable cycles without loss of accuracy. Automotive systems leverage these guides in welding robots and paint shop automation, where elevated temperatures from processes or ovens demand reliable linear motion for assembly line consistency. In precision equipment, such as semiconductor manufacturing tools or glass processing machinery, the series provides stable guidance for stages and actuators in heated chambers, supporting micron-level accuracy in tasks like wafer handling or laser cutting. By combining thermal resilience with high-performance mechanics, THK's RSX M1WN SERIES enables enhanced productivity and reliability across these critical sectors.

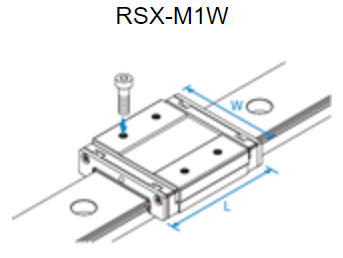

The THK LM Guide RSX M1W SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature environments where conventional guides would falter. This full ball type LM Guide incorporates a unique design where recirculating balls make full contact along the raceways, ensuring uniform load distribution and enhanced rigidity. Constructed from heat-resistant materials, including specially treated steel and high-temperature stable polymers, the RSX M1W maintains operational integrity in ambient temperatures up to 150°C, with intermittent peak resistance even higher. Its seals and lubricants are formulated to resist degradation, preventing grease leakage and dust ingress under thermal stress.

Key technical features define its robust performance. The guide utilizes a compact, high-rigidity structure with an increased ball count and optimized groove geometry, which collectively boost load capacity and moment resistance. Precision grinding of all raceway surfaces ensures smooth, low-friction motion with minimal running noise. A highly effective sealing system—comprising metal and rubber seals—provides multi-directional protection against contaminants like chips, dust, and splashing liquids, crucial in harsh settings. Pre-load adjustments are available to eliminate backlash, enhancing positional accuracy for demanding applications.

Performance advantages are substantial in thermally challenging scenarios. The RSX M1W delivers consistent precision and longevity where thermal expansion would typically compromise accuracy. Its high-temperature resilience reduces maintenance frequency and downtime, as components resist wear, deformation, and lubrication breakdown. The guide’s stability supports high-speed operation with minimal vibration, contributing to improved machining or assembly quality. Energy efficiency is another benefit, as the low-friction design requires less driving force, lowering power consumption in automated systems.

Typical applications span industries where heat and precision intersect. In industrial machinery, it is ideal for furnace door mechanisms, heat treatment equipment transfers, and injection molding machine ejectors, where sustained high temperatures are routine. Automotive manufacturing employs these guides in welding line robots, paint shop conveyors, and engine test stands, where environmental heat and process-generated warmth are factors. Precision equipment applications include semiconductor manufacturing apparatus, such as wafer handling in high-temperature deposition or etching processes, and glass processing machinery for tempering or forming operations. The RSX M1W SERIES ensures reliability, accuracy, and durability, making it a critical component in advancing productivity and innovation in thermally intensive sectors.

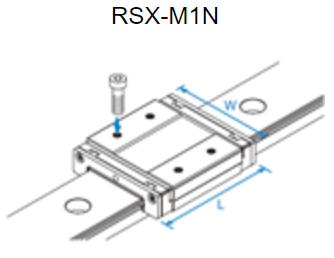

THK's LM Guide RSX M1N SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature environments where conventional guides would falter. This full ball type LM Guide incorporates a robust, heat-resistant design that maintains precision and reliability even when exposed to elevated temperatures up to 150°C continuously, with peak resistance reaching 200°C under certain conditions. The RSX M1N utilizes a unique ball circulation system that ensures smooth, consistent motion by maximizing contact between the balls and raceways, distributing loads evenly and reducing stress concentrations. Key technical features include the use of specially formulated heat-resistant steel for the rails and blocks, advanced sealing mechanisms that prevent ingress of contaminants like dust and debris while retaining lubrication, and a compact, low-profile structure that saves space without sacrificing load capacity or rigidity.

Performance advantages of the RSX M1N SERIES are substantial in demanding applications. Its high-temperature resilience minimizes thermal expansion effects, preserving accuracy and repeatability in positioning tasks. The full ball design enhances load-carrying capacity, supporting higher moment loads and offering improved stability under dynamic conditions, which translates to longer service life and reduced maintenance intervals. Friction is minimized through precision machining and optimized ball geometry, leading to smoother operation, lower energy consumption, and quieter performance. Additionally, the guide's corrosion-resistant coatings and seals extend durability in harsh environments, making it a cost-effective solution by reducing downtime and replacement frequency.

Typical applications span industries where heat and precision intersect. In industrial machinery, the RSX M1N is ideal for furnace door mechanisms, heat treatment equipment, and plastic injection molding machines, where components must endure cyclic thermal stresses without degradation. Automotive systems benefit from its use in engine test stands, exhaust handling robotics, and welding apparatus, where high temperatures and repetitive motions demand robust linear guidance. In precision equipment, it finds roles in semiconductor manufacturing tools, such as wafer handling and lithography stages, where thermal stability is critical to maintaining micron-level accuracy. By delivering reliable performance under thermal duress, the THK LM Guide RSX M1N SERIES enables enhanced productivity and longevity in applications that push the boundaries of conventional linear motion systems.

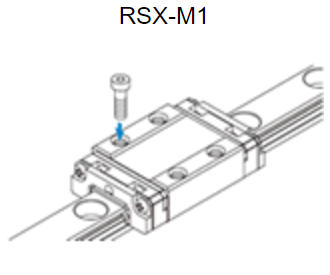

THK's LM Guide RSX M1 SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature environments where conventional guides would falter. This full ball type LM Guide incorporates a unique design with a retainer that prevents ball-to-ball contact, ensuring smooth, consistent motion even under extreme thermal conditions. The RSX M1 is constructed from heat-resistant materials, including specially treated stainless steel for the rail and shaft, and a glass cloth-based phenolic resin for the retainer, allowing it to operate reliably in ambient temperatures up to 150°C. Its sealed design, featuring both metal and rubber seals, effectively excludes contaminants like dust, chips, and high-temperature debris, while retaining lubrication to extend service life.

Key technical features include a compact, low-profile structure that saves space in machinery layouts, and a high rigidity design that withstands substantial loads in all directions—radial, reverse-radial, and lateral. The full ball contact between the balls and raceways distributes stress evenly, enhancing load capacity and reducing wear. Performance advantages are significant: the RSX M1 delivers high precision with minimal friction and smooth rolling motion, maintaining accuracy over long periods without adjustment. Its durability in high-heat settings reduces maintenance frequency and downtime, while the corrosion-resistant materials and effective sealing make it suitable for harsh, unclean environments. Noise levels are notably low due to the ball retainer, which eliminates ball collision sounds, contributing to quieter operation in sensitive applications.

Typical applications span industries where heat and precision intersect. In industrial machinery, the RSX M1 is ideal for furnace door mechanisms, heat treatment equipment, and injection molding machines where components are exposed to elevated temperatures during processing. Automotive systems benefit from its use in engine test stands, exhaust handling robotics, and welding lines in assembly plants, where heat from engines or welding processes demands robust linear motion. In precision equipment, it finds roles in semiconductor manufacturing tools, such as wafer handling in high-temperature chambers, and in packaging machinery for hot-fill processes. Its reliability ensures consistent performance in automated systems, supporting productivity in demanding settings like food processing ovens or glass manufacturing lines, where temperature resilience and contamination resistance are critical for uninterrupted operation.

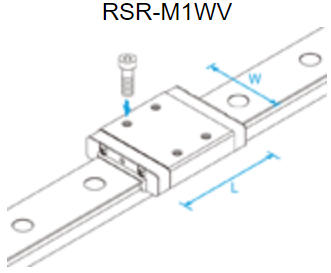

The THK LM Guide RSR M1WV SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature industrial environments where conventional guides would falter. This full ball type LM Guide incorporates a unique recirculating system with a resin retainer that maintains precision and reliability even when exposed to elevated temperatures up to 150°C. The design features a compact, high-rigidity structure with four load-bearing rows of balls arranged in a Gothic arch groove pattern, ensuring optimal load distribution and smooth, nearly frictionless motion. Each component is manufactured from heat-resistant materials, including specially treated steel for the rails and blocks, and high-temperature compatible resins and seals that prevent degradation and maintain lubrication integrity under thermal stress.

Key technical features include the RSR (Resin Retainer) mechanism, which effectively minimizes ball-to-ball contact, reducing noise, vibration, and wear while enhancing operational smoothness. The M1WV series is pre-loaded to eliminate backlash, providing high positional accuracy and repeatability essential for precision applications. Its sealed design incorporates specialized wipers and end seals that effectively exclude contaminants like dust, chips, and moisture, while retaining grease lubrication in harsh conditions. The guide also offers excellent corrosion resistance, making it suitable for environments with exposure to coolants or other aggressive substances.

Performance advantages are substantial in demanding settings. The high-temperature capability ensures consistent operation in processes such as heat treatment furnaces, welding lines, or automotive painting systems, where thermal expansion and material softening typically compromise performance. The low friction coefficient translates to reduced power consumption and heat generation, extending the service life of both the guide and associated machinery. Its high load capacity—supporting moments and loads in all directions—enables stable, vibration-damped motion that improves machining accuracy and surface finish quality. Maintenance requirements are minimal due to the long-term lubrication retention and robust sealing, reducing downtime and total cost of ownership.

Typical applications span multiple sectors where precision and thermal resilience are critical. In industrial machinery, the RSR M1WV is deployed in injection molding machines, die casting equipment, and semiconductor manufacturing systems where heated platens or ambient temperatures challenge standard components. Automotive production lines utilize these guides in robotic welding arms, assembly conveyors, and paint shop automation that operate near ovens or curing zones. Precision equipment applications include laser processing machines, optical positioning stages, and measurement instruments used in research or quality control environments subject to thermal fluctuations. By combining high-temperature endurance with refined motion control, this series enables enhanced productivity, reliability, and precision in the most thermally challenging industrial applications.

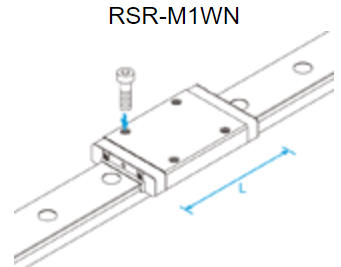

THK's LM Guide RSR M1WN SERIES represents a specialized linear motion solution engineered for high-temperature environments where standard components would fail. This full ball type LM Guide incorporates unique material selections and design innovations to maintain precision, load capacity, and longevity under continuous operating temperatures up to 150°C. The system features a stainless steel retainer and specially formulated heat-resistant engineering plastics that prevent deformation, seizure, or lubrication breakdown when exposed to sustained thermal stress. Races and balls are manufactured from through-hardened stainless steel, providing inherent corrosion resistance while retaining mechanical properties at elevated temperatures. A optimized sealing system combines metal and rubber seals to exclude contaminants like dust, chips, or fumes commonly found in industrial heating processes, while containing the high-temperature grease lubrication essential for smooth operation.

Performance advantages begin with maintained accuracy under thermal expansion, critical for precision positioning tasks in heated environments. The full ball contact design distributes loads evenly across four bearing points, delivering higher rigidity and stability than simplified linear guides. This configuration allows the RSR M1WN to handle moment loads effectively while providing smooth, low-friction motion with consistent precision over extended service life. The heat-resistant components prevent galling and retain proper preload, eliminating play that would compromise positioning accuracy. These guides exhibit minimal maintenance requirements despite harsh conditions, with lubrication intervals extended through specialized high-temperature greases.

Typical applications span industries where heat is inherent to the manufacturing process. In industrial machinery, these guides are deployed in semiconductor manufacturing equipment for wafer handling in high-temperature chambers, glass tempering lines where carriers move through heating and cooling zones, and plastic injection molding machines for ejector mechanisms operating near molten material. Automotive manufacturing utilizes these guides in painting line ovens where carriage systems transport components through curing cycles, and in engine test stands with heated environmental simulations. Precision equipment applications include laboratory automation in environmental testing chambers, food processing packaging machinery with steam sterilization requirements, and medical device sterilization systems where components must maintain accuracy through repeated high-temperature cycles. The RSR M1WN SERIES enables reliable linear motion where thermal challenges would compromise conventional guide systems, ensuring precision and durability in the most demanding heated applications.

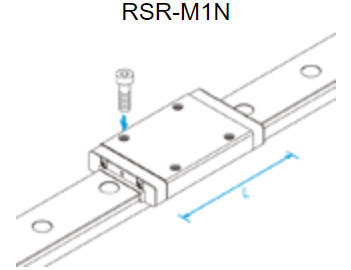

THK's LM Guide RSR M1N Series represents a significant advancement in linear motion technology, specifically engineered for high-temperature environments where conventional guides would falter. This full ball-type LM Guide incorporates a unique recirculating system with a resin end cap, ensuring smooth, reliable motion even under extreme thermal conditions. The design features a compact, high-rigidity structure with four rows of balls arranged in a circular arc groove, providing equal load capacity in all directions—radial, reverse-radial, and lateral. Key components include the rail, block, balls, retainer, and end seals, all constructed from heat-resistant materials to maintain performance integrity.

Technical features of the RSR M1N Series are tailored for durability and precision. The use of specially treated steel and heat-resistant resins allows continuous operation in ambient temperatures up to 150°C, with short-term peaks tolerated even higher. The full ball-type configuration maximizes ball-to-raceway contact, distributing loads evenly and reducing stress concentrations. This results in high rigidity and minimal elastic deformation under heavy or moment loads. The guide also incorporates advanced sealing technology, such as metal scrapers and labyrinth seals, which effectively exclude contaminants like dust, chips, and moisture, extending service life in harsh conditions. Additionally, the optimized recirculation path minimizes noise and vibration, contributing to smoother motion profiles.

Performance advantages stem from these design elements, offering enhanced accuracy, longevity, and efficiency. The RSR M1N Series delivers exceptional positional repeatability and low friction, enabling precise linear movements with minimal maintenance requirements. Its high load capacity and rigidity support demanding applications without sacrificing speed or stability. The heat resistance ensures consistent performance in thermally dynamic settings, reducing the risk of thermal expansion-induced inaccuracies. Energy efficiency is another benefit, as the low friction coefficient translates to reduced power consumption for driving mechanisms. These attributes make it a reliable choice for reducing downtime and total cost of ownership in industrial settings.

Typical applications span various sectors, leveraging its robustness and thermal resilience. In industrial machinery, it is commonly used in injection molding machines, where high temperatures from molten plastics are prevalent, or in furnace door mechanisms and heat treatment equipment. Automotive systems benefit from its integration into welding robots, paint shop conveyors, and engine test stands, where exposure to heat and contaminants is routine. For precision equipment, the RSR M1N Series finds use in semiconductor manufacturing apparatus, such as wafer handling robots and lithography stages, where clean, accurate motion is critical. It also serves in food processing machinery and packaging systems, where high-temperature sterilization processes occur. By addressing the challenges of high-temperature operations, this LM Guide enables innovation and reliability across these fields, supporting faster production cycles and improved product quality.

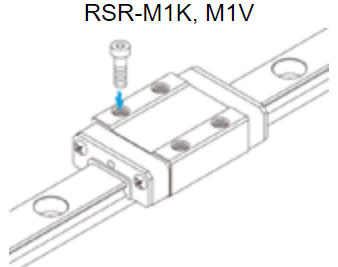

THK's LM Guide RSR M1K and M1V Series represent a specialized evolution in linear motion technology, engineered explicitly for high-temperature operational environments where standard guides would falter. These full ball-type LM Guides incorporate a robust, heat-resistant design that maintains precision and reliability even when exposed to elevated temperatures, making them indispensable in industries demanding unwavering performance under thermal stress.

The technical foundation of the RSR M1K and M1V Series is its full ball-type recirculating system. This design ensures a high load capacity and rigidity by maximizing the number of load-bearing balls in contact with the raceway. The components are manufactured from specially selected, heat-treated steels and utilize high-temperature synthetic lubricants. This material science is critical, as it prevents degradation of mechanical properties, such as hardness and dimensional stability, and avoids lubricant failure, which is a common point of failure in conventional guides. The seals are also engineered from heat-resistant materials to retain lubrication and exclude contaminants effectively, ensuring a long service life and consistent motion smoothness.

Performance advantages are significant and directly address the challenges of harsh applications. The foremost benefit is sustained operational integrity in ambient temperatures that would cause standard linear guides to experience premature wear, loss of preload, or catastrophic seizure. This results in dramatically extended maintenance intervals and reduced machine downtime. The guides offer high positional accuracy and smooth, low-friction motion, which is essential for precision processes. Their high rigidity and load capacity translate to improved stability and reduced vibration in the machinery, leading to higher quality output and the ability to handle heavier loads without sacrificing precision.

Typical applications for the THK RSR M1K and M1V Series are found wherever heat is an inherent byproduct of the process. In industrial machinery, they are pivotal in furnace door mechanisms, injection molding machines near heating barrels, and high-temperature material handling systems. The automotive industry utilizes these guides in manufacturing processes such as painting and curing ovens, where components must glide smoothly on tracks through intense, consistent heat. Within precision equipment, they are employed in semiconductor manufacturing, particularly in lithography and wafer processing stages that involve thermal cycles. Any application requiring reliable, precise linear motion in a sustained high-temperature environment is a candidate for this specialized series, ensuring that machinery can perform its core functions without being limited by its foundational motion components.

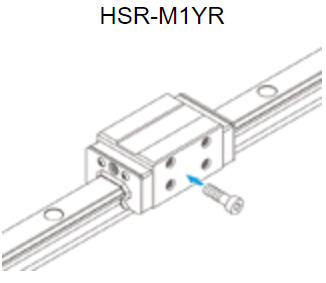

The THK LM Guide HSR M1YR SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature environments where conventional guides would falter. As a full ball type LM Guide, it incorporates a recirculating ball bearing system within a robust structure, ensuring smooth, precise linear movement even under extreme thermal conditions. This series is designed to maintain operational integrity and performance consistency in applications where ambient temperatures or process-generated heat would typically degrade lubrication, induce thermal expansion, or accelerate wear in standard linear guides.

Key technical features define the HSR M1YR's capability to withstand thermal challenges. Its core innovation lies in a heat-resistant design, utilizing specially selected materials for critical components like the ball retainers and end seals. These materials are formulated to resist softening, cracking, or outgassing at elevated temperatures. The lubrication system is another critical aspect; it is pre-packed with a high-temperature grease that retains its viscosity and lubricating properties, preventing drying, carbonization, or breakdown that leads to increased friction and eventual system seizure. The full ball contact design between the rail and the block ensures high rigidity and load capacity, distributing forces evenly across a large contact area for superior stability and accuracy. Furthermore, the integrated seals are engineered to remain pliable and effective, providing a robust defense against contaminants like dust, chips, and splashing liquids, which is crucial in harsh industrial settings.

The performance advantages derived from these features are significant. The most prominent is exceptional thermal stability, allowing the guide to operate reliably in environments exceeding the limits of standard models, thereby reducing downtime for cooling or maintenance. This directly translates to enhanced machine uptime and productivity. The maintained lubrication integrity ensures consistent, low-friction motion over extended periods, which preserves positioning accuracy and repeatability—a non-negotiable requirement in precision manufacturing. The high rigidity and load capacity contribute to reduced vibration and deflection under load, leading to improved machining quality and surface finishes. From a lifecycle perspective, the robust construction and specialized materials result in reduced wear rates, extending the service interval and lowering the total cost of ownership by minimizing unplanned failures and component replacements.

Typical applications for the HSR M1YR SERIES are found in industries where high temperatures are an inherent part of the process. In industrial machinery, it is indispensable for furnace door mechanisms, heat treatment handling equipment, injection molding machines near heating barrels, and die-casting equipment. The automotive industry utilizes these guides in manufacturing processes such as painting and curing ovens, engine component test stands, and brake disc manufacturing lines where components are handled at high temperatures. Within precision equipment, they are critical for semiconductor manufacturing apparatus, including wafer processing stations and inspection systems that operate in thermally demanding cleanroom environments. Any application demanding precise, reliable linear motion where heat is a persistent factor is a candidate for the robust performance of the HSR M1YR SERIES.

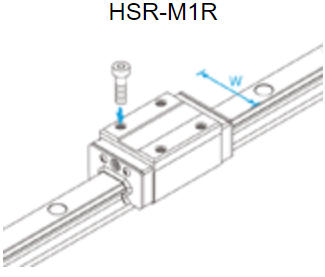

The THK LM Guide HSR M1R SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature industrial environments where conventional guides would falter. As a full ball type LM Guide, it incorporates a recirculating ball bearing system within a rigid, heat-resistant structure, ensuring smooth, precise linear movement under sustained thermal stress. The guideway and block are manufactured from superior-grade steel subjected to THK's proprietary heat treatment processes, enhancing surface hardness and core toughness to resist deformation and wear at elevated temperatures. Critical sealing systems employ high-temperature resistant grease and specialized rubber seals that maintain lubrication integrity and prevent contaminant ingress even when ambient conditions exceed standard operational limits.

Technical features defining the HSR M1R SERIES include its optimized ball groove geometry, which ensures consistent ball recirculation and load distribution across all contact points. The full ball contact design maximizes the number of load-bearing balls compared to standard designs, significantly increasing load capacity—both static and dynamic—while maintaining low friction coefficients. Preload adjustments are finely tunable, allowing for minimal backlash and high rigidity, which is crucial for precision positioning. The series is designed to operate reliably in environments where temperatures consistently range up to 150°C, with intermittent tolerance even higher, thanks to stabilized material properties and thermal-compensated clearances.

Performance advantages are substantial in demanding applications. The high-temperature capability eliminates downtime in processes like automotive paint curing ovens or plastic injection molding machines, where guides are exposed to radiant or conducted heat. Its high load capacity supports heavy machining heads or actuators in industrial robotics without sacrificing precision. Low noise and smooth motion characteristics make it suitable for precision equipment such as semiconductor manufacturing apparatus, where vibration and particulate generation must be minimized. The durability under thermal cycling reduces maintenance frequency and extends service life, lowering total cost of ownership.

Typical applications span multiple sectors. In industrial machinery, the HSR M1R SERIES is deployed in furnace door mechanisms, die-casting equipment, and high-temperature conveyor systems. Automotive manufacturing utilizes these guides in welding line transfer units, engine assembly palletizers, and brake disc processing machines where heat from nearby processes is inevitable. Precision equipment applications include LCD panel manufacturing lines, where glass substrate handling requires stability in heated chambers, and optical lens polishing machines that generate significant frictional heat. By maintaining accuracy and reliability where heat would degrade ordinary linear guides, the HSR M1R SERIES enables continuous operation in the most thermally challenging industrial automation, automotive, and precision technology environments.

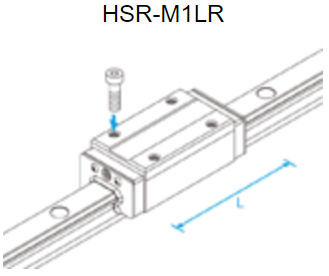

The THK LM Guide HSR M1LR SERIES represents a specialized advancement in linear motion technology, engineered specifically for high-temperature environments where conventional guides would falter. This full ball type LM Guide incorporates a robust design with precision-ground raceways and a comprehensive ball recirculation system, ensuring smooth, low-friction linear movement even under extreme thermal conditions. Key technical features include the use of heat-resistant materials for critical components such as the rail, block, and balls, which maintain structural integrity and dimensional stability at elevated temperatures up to 150°C. The seals and retainers are optimized for thermal resistance, preventing lubricant degradation and contamination ingress, while the large ball diameter and optimized contact angle enhance load capacity and rigidity.

Performance advantages of the HSR M1LR SERIES are substantial in demanding applications. Its high-temperature resilience minimizes thermal expansion effects, preserving accuracy and repeatability over prolonged operation. The full ball design distributes loads evenly across multiple contact points, reducing wear and extending service life, which translates to lower maintenance costs and reduced downtime. With low noise and vibration characteristics, it contributes to quieter machinery operation, and its efficient sealing system ensures consistent lubrication retention, critical for high-speed or continuous-duty cycles. These attributes make it ideal for environments where thermal fluctuations are common, offering reliable performance without compromising on precision.

In industrial machinery, the HSR M1LR SERIES finds typical applications in equipment such as injection molding machines, where heated platens and prolonged cycles subject components to sustained high temperatures. It ensures precise mold positioning and smooth ejection processes, enhancing product quality and throughput. In automotive systems, it is employed in engine test stands, exhaust component assembly lines, and braking system manufacturing, where elevated temperatures from nearby processes or internal heat generation demand robust linear guidance. For precision equipment, this series supports high-accuracy tasks in semiconductor manufacturing tools, such as wafer handling and lithography stages, where thermal stability is paramount to maintain micron-level tolerances. Overall, the THK HSR M1LR SERIES delivers durability and precision, making it a cornerstone for industries reliant on dependable linear motion in challenging thermal conditions.

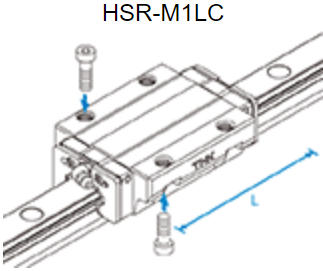

THK's LM Guide HSR M1LC SERIES represents a specialized linear motion solution engineered for high-temperature environments where standard components would falter. As a full ball type LM Guide, it incorporates a recirculating ball bearing system within a robust carriage and rail assembly, ensuring smooth, precise linear motion under demanding thermal conditions. The series is constructed from heat-resistant materials, including specially treated steel and high-temperature grease, allowing continuous operation in ambient temperatures up to 150°C and peak resistance to 200°C. This thermal resilience is critical for applications involving process heat, friction-induced warmth, or proximity to heating elements.

Key technical features distinguish the HSR M1LC in performance and reliability. Its full ball contact design maximizes load distribution across all rolling elements, significantly enhancing rigidity and load capacity while minimizing deformation under stress. The guide incorporates a highly efficient sealing system with multi-layer contact seals and metal scrapers that prevent ingress of contaminants like dust, chips, or splashing liquids, even as material properties shift with temperature. Pre-loaded ball circuits eliminate internal clearance, delivering high positional accuracy and repeatability essential for precision tasks. Additionally, the optimized recirculation system reduces noise and vibration, contributing to smoother operation and extended service life by mitigating wear.

Performance advantages are evident in its operational stability and longevity. The high-temperature compatibility ensures consistent precision and minimal thermal expansion effects, maintaining alignment and reducing downtime for recalibration. Its high rigidity allows for higher loads and moments, supporting heavier components or more aggressive machining without sacrificing accuracy. The low-friction coefficient of the ball bearings translates to reduced drive power requirements, enhancing energy efficiency in continuous operations. Maintenance intervals are extended due to the durable construction and effective sealing, lowering total cost of ownership.

Typical applications span industries where heat and precision intersect. In industrial machinery, the HSR M1LC is deployed in injection molding machines for ejector mechanisms, die-casting equipment for linear actuation, and furnace door systems requiring reliable movement under radiant heat. Automotive manufacturing utilizes these guides in welding robots operating near high-temperature processes, engine assembly lines for positioning components, and brake testing equipment subjected to frictional heat. Within precision equipment, they are integral to semiconductor manufacturing tools like wafer handling robots, where cleanroom compatibility and thermal stability are paramount, and in packaging machinery for sealing stations that generate consistent heat. This versatility makes the series a cornerstone for advancing automation in challenging thermal environments.

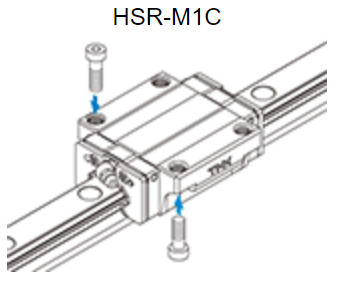

THK's LM Guide HSR M1C SERIES represents a specialized evolution in linear motion technology, engineered specifically for high-temperature environments where standard components would falter. This full ball type LM Guide incorporates a robust, precision-ground rail and block assembly with a circular arc groove design, ensuring optimal ball contact and load distribution. The series is constructed from heat-resistant steel, capable of continuous operation in ambient temperatures up to 150°C and peak exposures reaching 200°C. Critical to its performance is the use of specially formulated heat-resistant seals and high-temperature grease, which maintain lubrication integrity and prevent contamination from dust, chips, or moisture even under thermal stress. The retainer mechanism securely holds the balls within the block, eliminating the risk of displacement during high-speed strokes or maintenance disassembly.

Technical features that define the HSR M1C SERIES include its high load capacity, achieved through a full complement of balls that maximize contact area with the raceways. This design supports significant loads in all directions—radial, reverse-radial, and lateral—making it exceptionally stable under complex force conditions. The guide offers precision grades from high accuracy to super-precision, with running parallelism tolerances as tight as 7μm, ensuring repeatable linear movement essential for demanding applications. Its corrosion-resistant properties, enhanced by optional coatings or material selections, further extend service life in harsh settings. The compact cross-section and standardized mounting dimensions facilitate easy integration into existing machinery layouts without extensive modifications.

Performance advantages are most evident in operational reliability and longevity. The heat-resistant construction minimizes thermal deformation, preserving accuracy over prolonged use. Smooth, low-friction motion reduces energy consumption and minimizes heat generation from the guide itself. Maintenance intervals are extended due to the durable seals and high-temperature lubricant, lowering total cost of ownership. The guide's rigidity dampens vibrations, contributing to quieter operation and protecting sensitive attached components from shock impacts.

Typical applications leverage these strengths across multiple sectors. In industrial machinery, the HSR M1C SERIES is indispensable for furnace door mechanisms, heat treatment conveyor systems, injection molding machines, and die-casting equipment where exposure to elevated temperatures is constant. Automotive manufacturing utilizes these guides in painting and curing ovens, engine assembly lines, and brake testing systems that require precise positioning under thermal load. Within precision equipment, they are found in semiconductor manufacturing apparatus, such as wafer handling robots and lithography stages, where thermal stability is critical to micron-level accuracy. Food processing packaging machinery and glass manufacturing systems also benefit from its ability to perform reliably in sterilizing or annealing heat zones, ensuring uninterrupted production cycles and consistent output quality.