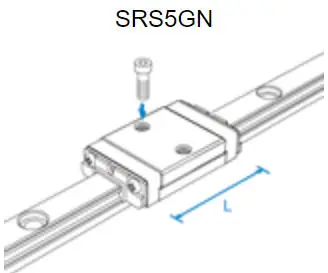

The THK LM Guide SRS5GN Series represents a compact, high-performance linear motion solution engineered for applications where space constraints and precision are paramount. This miniature full-ball type LM Guide incorporates a unique design where the ball rolling grooves are precision-ground into both the rail and the block, forming a Gothic arch structure. This configuration provides four contact points for each ball, ensuring high rigidity, exceptional accuracy, and smooth, stable motion with minimal friction. The series is characterized by its compact cross-sectional dimensions, making it an ideal choice for miniaturized equipment and devices requiring a small footprint without compromising on load capacity or guiding precision.

Key technical features of the SRS5GN Series include its full-ball, recirculating design, which maximizes the number of load-bearing balls within the compact block. This design directly contributes to a high load rating and stiffness. The components are manufactured from high-carbon chromium bearing steel, heat-treated to achieve a surface hardness that ensures long-term durability and wear resistance. The integrated seals are highly effective at preventing the ingress of contaminants like dust and debris, while simultaneously retaining the grease lubrication within the system. This combination significantly extends the operational life and maintains consistent performance even in environments with moderate particulate contamination.

The performance advantages of this series are substantial for precision-driven industries. Its compact size allows for direct integration into slender mechanisms, reducing the overall size and weight of the final assembly. The high rigidity and accuracy enable precise positioning and repeatability, which is critical in automated processes. Furthermore, the low friction coefficient translates into high efficiency, requiring less driving force and contributing to energy savings. The sealed design ensures reliable, maintenance-free operation over extended periods, reducing downtime and total cost of ownership.

Typical applications for the THK SRS5GN LM Guide are found across a spectrum of high-tech industries. In industrial machinery, it is extensively used in the linear axes of compact CNC machining centers, precision assembly robots, and the sliding bases of semiconductor and electronic component manufacturing equipment. Within the automotive sector, these guides are employed in precision testing and measurement instruments, as well as in automated assembly systems for small components. In the realm of precision equipment, the SRS5GN is a critical component in medical devices, optical instruments, and laboratory automation systems where smooth, precise, and reliable linear motion is non-negotiable. Its miniature profile and robust performance make it a fundamental building block for advancing miniaturization and automation across modern manufacturing and technology sectors.

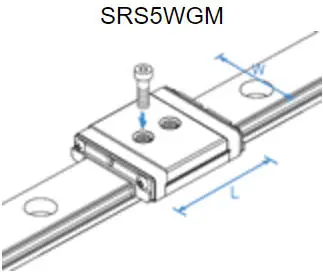

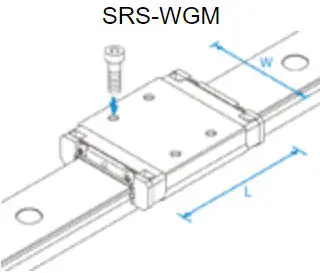

The THK LM Guide Miniature Model SRS G SRS5WGM SERIES represents a compact, high-precision linear motion solution engineered for applications where space constraints and demanding performance criteria converge. As a full ball type LM Guide, this series incorporates a complete ball recirculation system within a remarkably small cross-section, delivering smooth, precise linear movement with minimal friction and exceptional rigidity. The design features a compact, lightweight structure with a low profile, making it ideal for integration into tight spaces without sacrificing performance. Key technical attributes include a highly rigid structure capable of withstanding substantial loads, including moment loads, while maintaining precise alignment and smooth operation. The full ball contact design ensures uniform load distribution across all ball grooves, enhancing load capacity and service life while minimizing wear. Precision-ground raceways and optimized ball groove geometry contribute to low noise operation, high positional accuracy, and consistent performance over extended periods.

Performance advantages of the SRS5WGM SERIES are significant across multiple dimensions. Its compact design allows for direct mounting in confined areas, reducing overall system size and weight while maintaining high load capacity and rigidity. The full ball recirculation system provides smooth, nearly frictionless motion with excellent positioning accuracy and repeatability, critical for precision applications. High-speed capability is achieved through optimized ball circulation and reduced vibration, while the sealed design with integrated wipers and seals effectively excludes contaminants, ensuring reliable operation in challenging environments. These features collectively contribute to extended service life, reduced maintenance requirements, and consistent performance under varying operational conditions. The series demonstrates particular strength in handling combined loads – simultaneously managing radial, reverse radial, and lateral forces while maintaining precise guidance and minimal deflection.

Typical applications span multiple industries where precision, reliability, and compact design are paramount. In industrial automation and machinery, these guides are deployed in precision positioning stages, small assembly robots, measuring instruments, and semiconductor manufacturing equipment where space optimization and accurate motion control are critical. The automotive industry utilizes them in precision testing equipment, small robotic welders, and assembly line automation components requiring dependable linear motion in compact installations. For precision equipment applications, the SRS5WGM SERIES finds implementation in medical devices, optical positioning systems, laboratory automation, and precision measuring instruments where smooth, accurate linear motion must be maintained within strictly limited spaces. The combination of miniature dimensions and high performance characteristics makes this series particularly suitable for advanced applications in electronics manufacturing, including PCB assembly equipment, component insertion machines, and precision inspection systems where multiple axes of motion must be coordinated within tightly constrained volumes.

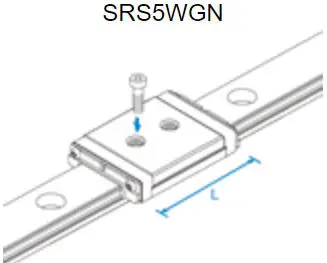

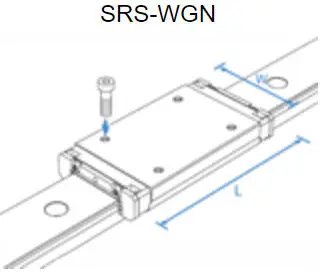

The THK LM Guide LM Guide (full ball type) Miniature Model SRS G SRS5WGN SERIES represents a compact, high-precision linear motion solution engineered for applications where space constraints and demanding performance criteria converge. This series incorporates a full-ball type design, where the entire circumference of the shaft is utilized as a raceway, enabling the carriage to support loads from all directions—radial, reverse-radial, and lateral. This fundamental architecture is the cornerstone of its exceptional rigidity and moment load capacity, even within its miniature form factor. The SRS5WGN model specifically features a stainless steel (SUS440) shaft with a resin end seal, providing inherent corrosion resistance and effective protection against contaminants in challenging environments.

Technically, the SRS G series is distinguished by its optimized ball groove profile and precision-ground components, which work in unison to deliver smooth, near-silent motion with exceptionally low friction and high positional accuracy. The incorporation of a full-complement ball arrangement, without a ball retainer, maximizes the number of load-carrying balls in contact with the raceways. This design significantly increases load capacity and stiffness while simultaneously distributing wear over a greater number of contact points, leading to a dramatically extended service life and consistent performance over time. The compact carriage design minimizes the overall mounting space required, making it an ideal drop-in replacement or new design component for miniaturized machinery.

The performance advantages of the SRS5WGN SERIES are substantial. Its high rigidity translates into minimal deflection under load, which is critical for maintaining precision in machining and assembly operations. The low coefficient of friction ensures high efficiency, reducing drive power requirements and minimizing heat generation. Furthermore, the sealed design, often enhanced with optional grease fittings for easy re-lubrication, ensures long-term reliability and reduces maintenance intervals, even in environments with fine dust, chips, or occasional liquid splash.

Typical applications for this miniature LM Guide are found across industries that demand precision and reliability in a small package. In industrial automation, it is extensively used in the linear axes of compact pick-and-place robots, precision assembly machines, and the sliding stages of semiconductor and electronic component manufacturing equipment. Within the automotive sector, it finds purpose in precision sensors, advanced headlight leveling mechanisms, and small-scale testing and measurement apparatus. For broader precision equipment, the SRS5WGN is a critical component in medical devices such as DNA analyzers and lab automation systems, optical positioning stages, and high-accuracy coordinate measuring machines (CMM) probes, where its compact size, high stiffness, and smooth motion are indispensable for achieving micron-level accuracy.

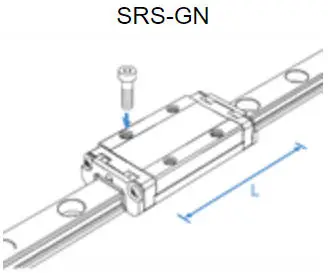

THK's LM Guide Miniature Model SRS G, SRS GM, and SERIES represent a specialized class of linear motion components engineered for applications where space is at a premium but performance cannot be compromised. These full-ball-type LM Guides are characterized by their compact cross-sectional dimensions and lightweight construction, making them an ideal solution for integrating precise linear movement into tightly constrained designs. The fundamental design incorporates a recirculating ball bearing system within a guide block that travels along a precision-ground rail. This "full ball" configuration ensures a large number of balls are in contact with the raceways at any given time, distributing loads evenly and contributing to the unit's remarkable load capacity and rigidity despite its miniature size.

The technical features of these series are meticulously crafted for high performance. The SRS models often feature a stainless steel construction for the guide block and balls, providing excellent corrosion resistance—a critical attribute for environments exposed to moisture, chemicals, or in cleanroom applications. The integrated seal systems are highly effective at excluding contaminants like dust and chips while retaining lubricant, significantly extending service life and maintenance intervals. The precision grinding of the rail raceways results in exceptionally smooth and quiet motion with minimal friction. A key performance advantage is their high accuracy and repeatability of positioning, achieved through low rolling friction and high rigidity that minimizes deflection under load. This combination allows for high-speed operation, rapid acceleration and deceleration, and precise stop-and-repeat movements without sacrificing stability or generating excessive noise and vibration.

These performance characteristics make the miniature SRS G and SRS GM SERIES indispensable across a diverse range of modern industries. In industrial automation and machinery, they are the driving component in compact pick-and-place units, precision assembly robots, and the linear axes of small CNC machines and measuring instruments. The automotive industry utilizes them within advanced manufacturing and testing equipment, such as in precision sensor positioning systems and automated inspection devices on production lines. Within the realm of precision equipment, these guides are found at the heart of semiconductor manufacturing apparatus, including wafer steppers and wire bonders, where nanometer-level precision is mandatory. They are equally critical in medical device manufacturing, powering the linear motion in diagnostic equipment, laboratory automation systems, and surgical robots, where reliability, compactness, and smooth, hygienic operation are paramount. Ultimately, THK's miniature LM Guides enable engineers to push the boundaries of miniaturization and precision without sacrificing the robust, reliable motion that modern machinery demands.

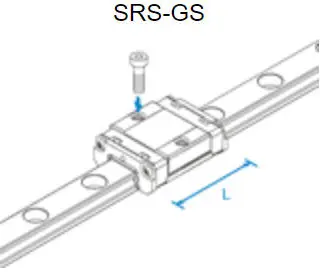

The THK LM Guide Miniature Model SRS G and SRS GN SERIES represent a specialized class of full ball type linear motion guides engineered for applications where space is at a premium but performance cannot be compromised. These compact guides are characterized by their use of a full-ball contact design between the ball grooves of the rail and the slider. This fundamental architecture ensures that the load-bearing balls circulate through a highly efficient, compact circuit within a single, integrated unit. The series is meticulously designed with a low profile, making it an ideal solution for modern, miniaturized machinery and equipment.

Technically, the SRS G/SRS GN series incorporates several critical features that define its performance. The full ball type design provides a large load rating relative to the guide's compact dimensions, supporting substantial loads in all four primary directions: radial, reverse radial, and lateral. This is achieved through a Gothic arch groove configuration that maximizes contact area and ensures stable, precise motion. The ball recirculation system is optimized for smooth, consistent movement with minimal resistance, contributing to high positional accuracy and repeatability. Many models within the series are available with optional seals or scrapers, which are highly effective at excluding contaminants like dust and chips while retaining lubrication, thereby ensuring long-term reliability and maintenance-free operation in harsh environments. The compact and lightweight construction of the slider and rail directly contributes to space-saving machine designs and reduced overall moving mass.

The performance advantages of this miniature series are significant for precision-driven industries. The high rigidity and load capacity enable these guides to handle moment loads effectively, preventing deflection and ensuring stability during high-speed or high-acceleration movements. This results in exceptional tracking precision, minimal vibration, and quiet operation. The low friction coefficient of the full-ball circulation system translates into high mechanical efficiency, allowing for the use of smaller, more cost-effective drive motors and reducing overall energy consumption. Their durability and resistance to wear ensure a long service life, maintaining accuracy over millions of cycles.

Typical applications for the THK SRS G and SRS GN SERIES are found wherever compact, reliable linear motion is essential. In industrial automation, they are integral to the function of precision XY tables, small assembly robots, and the linear axes of pick-and-place machines. Within the electronics and semiconductor manufacturing sectors, they are deployed in chip mounters, wire bonders, and inspection equipment where microscopic precision is non-negotiable. The automotive industry utilizes these guides in advanced manufacturing and testing apparatus, including small-scale part handling systems and precision measurement devices. Furthermore, they are a cornerstone in the design of medical and laboratory automation, such as DNA analyzers and automated sample handling systems, where smooth, clean, and dependable motion is critical.

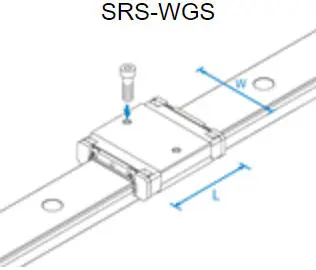

THK's LM Guide Miniature Model SRS G, SRS GS, and SERIES represent a specialized class of linear motion components engineered for applications where space is at a premium but performance cannot be compromised. These full ball-type LM Guides are characterized by their compact cross-sectional dimensions and lightweight construction, making them an ideal solution for integrating precise linear movement into tightly constrained designs. The series utilizes a unique ball circulation system where the load-bearing balls recirculate through a compact, efficient circuit within the block, ensuring smooth, continuous motion. The standardized models, such as the SRS G, feature a stainless steel track rail with resin end seals, while the SRS GS variant offers a stainless steel track rail combined with stainless steel end seals, providing enhanced corrosion resistance for more demanding environments. The design incorporates a four-row, circular-arc groove configuration that provides high rigidity and excellent load capacity in all directions—radial, reverse-radial, and lateral.

The performance advantages of these miniature guides are significant. Their compact size directly translates to space-saving designs, allowing for more streamlined and efficient machinery layouts. Despite their small stature, they deliver high precision, low friction, and exceptional smoothness of movement, which are critical for applications requiring high positional accuracy and repeatability. The full ball contact design ensures high rigidity and stability, minimizing deflection under load and contributing to improved system longevity and reliability. The optimized ball circulation system reduces vibration and noise during operation, a crucial factor in noise-sensitive environments. Furthermore, the availability of corrosion-resistant models extends their usability to harsh conditions, including those with exposure to moisture, chemicals, or washdowns, without sacrificing performance.

Typical applications for the THK Miniature LM Guide SRS G/SRS GS/SERIES are found across industries where precision, compactness, and reliability are paramount. In industrial automation and machinery, they are extensively used in the linear axes of small CNC machines, precision assembly robots, pick-and-place units, and measuring instruments. Within the semiconductor and electronics manufacturing sectors, these guides are critical components in wafer handling equipment, chip mounter mechanisms, and precision inspection stages. The automotive industry leverages them in advanced manufacturing systems for tasks like small-part assembly, sensor positioning, and inside compact testing apparatus. They are also fundamental in the creation of high-precision medical and optical equipment, such as DNA analyzers, lens positioning systems in microscopes, and automated diagnostic devices, where their smooth, accurate, and reliable motion is essential for the integrity of the process.

THK's LM Guide Miniature Model SRS G, SRS WGM SERIES represents a specialized evolution in compact linear motion technology, engineered specifically for applications where space constraints and precision are paramount. These full ball-type LM Guides utilize a unique design where balls circulate through a compact, precision-ground raceway, providing smooth, low-friction linear motion in miniature form factors. The series includes variations like the SRS G with standard accuracy and the SRS WGM with wider rails for enhanced moment load capacity, all built to maintain THK's rigorous standards for reliability and performance.

Key technical features distinguish these miniature guides in demanding environments. The full ball-type design ensures that load-bearing balls make complete contact with the raceways, distributing stress evenly and maximizing load capacity despite the small size. Precision manufacturing techniques result in tight tolerances on parallelism and flatness, critical for maintaining accuracy in miniature assemblies. Corrosion-resistant materials, including stainless steel options, allow operation in harsh or cleanroom environments without degradation. The compact cross-sections, with heights as low as 3.5mm and widths under 12mm in some models, enable integration into tightly spaced mechanical designs where traditional linear guides would be impractical.

Performance advantages stem directly from these design choices. The full ball recirculation system minimizes friction, yielding smooth motion with consistent precision even at high speeds, which reduces vibration and improves positional accuracy. High rigidity from the widened rail designs in the SRS WGM series resists moment loads effectively, preventing deflection under off-center loading. Long service life is achieved through optimized ball circulation that reduces wear, while the sealed designs with integrated wipers exclude contaminants like dust and chips, crucial for maintaining performance in unclean industrial settings. These guides operate quietly with low noise generation, making them suitable for noise-sensitive applications like medical or laboratory equipment.

Typical applications leverage their miniature size and precision across multiple industries. In industrial machinery, they guide sensors, actuators, and tool changers in automated assembly systems where space is limited but reliability cannot be compromised. Automotive systems employ them in precision fuel injection test equipment, transmission assembly jigs, and electronic throttle control mechanisms that demand compact, durable linear motion. Within precision equipment, these guides are integral to semiconductor manufacturing tools, optical positioning stages, and medical device components like DNA sequencers or robotic surgery arms, where micron-level accuracy and minimal particle generation are essential. Their versatility also extends to robotics, where they provide smooth articulation in joint mechanisms, and to packaging machinery for guiding small, high-speed pick-and-place units. By combining miniature dimensions with robust performance, the SRS G and SRS WGM SERIES deliver precise linear motion solutions where larger alternatives would be impossible, enabling innovation in compact mechanical design across advanced technological fields.

THK's LM Guide Miniature Model SRS G and SRS WGN SERIES represent the pinnacle of compact linear motion technology, engineered for applications where space constraints and precision are paramount. These full ball-type LM Guides utilize a unique design where balls circulate through a compact, integrated ball groove structure in both the rail and block. This configuration ensures smooth, highly accurate linear motion with minimal friction, making them ideal for high-speed, high-precision operations in demanding environments.

The technical features of these miniature guides are meticulously crafted to deliver superior performance. The SRS G series features a stainless steel construction for the rail and block, providing excellent corrosion resistance, which is critical in environments exposed to moisture, chemicals, or other corrosive agents. The SRS WGN series, on the other hand, incorporates a resin endplate that reduces weight and minimizes noise during operation, enhancing suitability for applications requiring quiet and efficient motion. Both series employ THK's advanced ball circulation system, which ensures consistent contact between the balls and raceways, distributing loads evenly and significantly extending service life. The compact dimensions of these guides, with heights as low as 3.5 mm and widths starting from 7 mm, allow for seamless integration into tightly spaced assemblies without compromising on load capacity or rigidity. Pre-loaded options are available to eliminate backlash, ensuring precise positioning and repeatability essential for fine adjustments and high-accuracy tasks.

Performance advantages of the SRS G and SRS WGN SERIES include exceptional durability, low maintenance requirements, and energy efficiency. The full ball-type design maximizes the number of load-bearing balls, enabling higher load capacities and stiffness compared to similarly sized competitors. This results in improved dynamic performance, with the ability to handle moment loads and accelerations smoothly. The guides' low coefficient of friction reduces power consumption, contributing to energy savings in continuous operation scenarios. Additionally, their sealed structures with optional seals protect against contaminants like dust and debris, maintaining performance in harsh industrial settings and reducing the need for frequent cleaning or lubrication.

Typical applications span across industries where precision and reliability are non-negotiable. In industrial machinery, these miniature LM Guides are integral to semiconductor manufacturing equipment, PCB drilling machines, and automated assembly lines, where they facilitate precise component placement and high-speed scanning. Within automotive systems, they are employed in fuel injection testing apparatus, small robotic actuators for welding or painting, and advanced driver-assistance systems (ADAS) calibration tools, ensuring accurate movements in confined engine or chassis spaces. For precision equipment, the SRS G and SRS WGN SERIES excel in medical devices such as laboratory analyzers, dental handpieces, and imaging systems, as well as in optical instruments like lens positioning stages and coordinate measuring machines, where smooth, vibration-free motion is crucial for achieving micron-level accuracies. Their compact, robust design makes them a versatile solution for advancing automation and precision in modern technology-driven sectors.

THK's LM Guide Miniature Model SRS G, SRS, and WGS SERIES represent a specialized category of linear motion components engineered for applications where space constraints, lightweight design, and precision are paramount. These full ball-type LM Guides utilize a compact, highly efficient recirculating ball bearing system within a minimized cross-sectional profile, making them ideal for integration into tight spaces without sacrificing performance or load capacity. The series is characterized by its robust construction, featuring a rail and block assembly manufactured from high-carbon chromium bearing steel, hardened to HRC 58-62, ensuring exceptional wear resistance and long-term operational accuracy.

Key technical features distinguish these miniature guides. The full ball-type design incorporates a large number of precision-ground steel balls that circulate smoothly through a compact, optimized load path. This configuration provides four-directional equal load capacity, meaning the guides can handle radial, reverse radial, and lateral loads with high rigidity and stability. The SRS G model, for instance, often includes a single-piece seal design to effectively protect the ball recirculation system from dust, chips, and other contaminants, thereby maintaining smooth motion and extending service life. The WGS series may offer variations in sealing or preload options to suit specific application demands. A critical performance advantage is their low coefficient of friction, which enables high-speed, smooth, and precise linear movement with minimal stick-slip. This results in exceptional positional accuracy and repeatability, crucial for processes demanding micron-level precision. Furthermore, their compact and lightweight nature reduces the overall mass of moving parts, contributing to higher acceleration rates, reduced energy consumption, and less inertia-induced vibration.

The performance advantages of these miniature LM Guides translate directly into enhanced capabilities for a wide range of advanced machinery. In the realm of industrial automation, they are indispensable in compact pick-and-place robots, precision assembly machines, and the linear axes of semiconductor and electronic component manufacturing equipment, where their small size and high accuracy are critical for handling miniature parts. Within automotive manufacturing systems, these guides are deployed in precision testing and measurement instruments, small-scale robotic welders, and automated inspection stations on production lines. For high-precision equipment, they form the core motion system in medical devices like DNA analyzers and lab automation systems, optical and laser processing equipment requiring vibration-free and jitter-free motion, and precision measuring instruments such as coordinate measuring machines (CMMs) and vision inspection systems. Their reliability, compactness, and high-speed precision make the THK Miniature SRS G, SRS, and WGS SERIES a fundamental component for engineers designing the next generation of compact, high-performance automated systems.

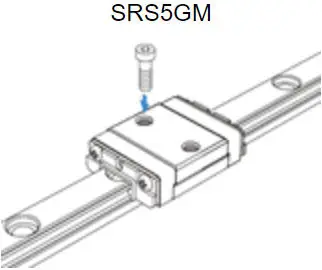

The THK LM Guide SRS5GM Series represents a compact, high-performance linear motion solution engineered for applications where space constraints and precision are paramount. This miniature full-ball type LM guide incorporates a unique design where the ball rolling grooves are precision-ground into both the rail and the block, forming a Gothic arch structure. This configuration provides four contact points per ball, significantly enhancing load capacity and rigidity while ensuring smooth, highly accurate linear motion with minimal friction. The series is characterized by its compact cross-sectional dimensions, making it an ideal choice for miniaturized equipment and devices.

Key technical features of the SRS5GM Series include its full-ball, recirculating design, which ensures a constant and smooth transfer of load-carrying balls within the compact block. The incorporation of a high-performance seal, often a combination of an End Seal and a Metal Scraper, is critical. This sealing system effectively prevents the ingress of contaminants like dust and chips while retaining essential lubrication, dramatically extending the component's service life even in demanding environments. The guide is manufactured from high-carbon chromium bearing steel, which is subjected to rigorous heat treatment processes to achieve a surface hardness that guarantees exceptional wear resistance and long-term precision retention.

The performance advantages derived from this design are substantial. The four-point contact structure offers high rigidity and moment load capacity, allowing the guide to withstand complex force scenarios, including overturning and lateral moments, without compromising motion accuracy. This results in exceptional positional repeatability and smooth, low-friction movement that minimizes stick-slip, a critical factor for precision positioning tasks. The compact and lightweight nature of the series enables the design of more streamlined machinery without sacrificing performance. Furthermore, the robust sealing and high-quality materials contribute to low maintenance requirements and high operational reliability, reducing total cost of ownership.

Typical applications for the THK SRS5GM Series are found across industries where miniaturization, precision, and reliability are non-negotiable. In industrial automation, these guides are integral to compact assembly robots, precision stages for semiconductor and electronics manufacturing, and the linear axes of miniature CNC equipment. Within the automotive sector, they are employed in advanced sensor testing apparatus, precision fuel injection system manufacturing jigs, and compact inspection devices. In the realm of precision equipment, the SRS5GM is a cornerstone component for optical instrument stages, medical device positioning systems, and high-accuracy measuring and testing machines, providing the stable and flawless motion required for the most sensitive and critical operations.