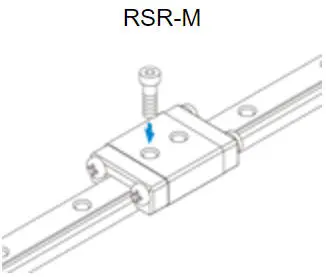

The THK LM Guide RSR M SERIES represents a compact, high-precision linear motion solution engineered for applications where space constraints and demanding performance criteria converge. As a miniature, full ball type LM guide, this series incorporates a robust, recirculating ball bearing system within a significantly reduced cross-sectional profile, delivering exceptional rigidity, smooth motion, and long service life in a minimal footprint. Its design is characterized by a rectangular rail and block assembly, where the ball grooves are precision-ground to form a Gothic arch structure. This geometry provides a high degree of contact between the balls and the raceways, resulting in superior load capacity and stiffness in all directions—radial, reverse-radial, and lateral.

Key technical features that define the RSR M SERIES include its optimized ball circulation system, which ensures smooth and consistent recirculation even at high speeds, minimizing vibration and noise generation. The incorporation of a high-performance seal and wiper system effectively excludes contaminants like dust, chips, and moisture, while retaining lubrication to enhance operational longevity in harsh environments. The compact design does not compromise on load handling; these guides are capable of supporting substantial loads relative to their size. Furthermore, the series is available in various accuracy grades and preload options, allowing for precise tuning to specific application requirements for minimal deflection and high positional accuracy.

The performance advantages of the RSR M SERIES translate directly into enhanced machine capability. Its high rigidity and accuracy ensure precise, repeatable positioning, which is critical for maintaining product quality. The low-friction motion contributes to higher operational speeds and improved energy efficiency, while the durable construction and effective sealing guarantee a long maintenance interval and exceptional reliability, reducing total cost of ownership. The miniature size enables the design of more streamlined and compact machinery without sacrificing performance.

Typical applications for the THK RSR M SERIES are found across industries where precision, compactness, and reliability are paramount. In industrial automation, they are integral to the function of compact CNC stages, precision assembly robots, and high-speed pick-and-place units. Within the automotive sector, these guides are employed in precision testing equipment, small-scale robotic welders, and automated inspection systems on production lines. In the realm of precision equipment, the RSR M SERIES is a critical component in semiconductor manufacturing apparatus, medical device instrumentation, optical positioning systems, and advanced 3D printers, where their small size and high accuracy are indispensable for achieving micron-level precision and reliable, high-speed cycling.

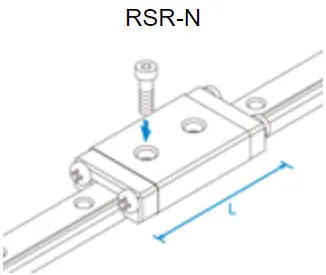

THK's LM Guide RSR/RSR N SERIES represents a specialized class of miniature linear motion guides utilizing a full-ball type design, engineered to deliver exceptional precision and reliability in compact, space-constrained applications. This series is characterized by its compact cross-section and the implementation of a full-ball, four-row circular arc groove design. In this configuration, balls are arranged in a complete loop, making contact at four points on the raceway. This architecture provides a significantly larger load-bearing capacity and higher rigidity compared to many conventional miniature guides, allowing it to withstand substantial loads—including radial, reverse-radial, and lateral moments—from all directions. The compactness is a key feature, enabling the integration of high-performance linear motion into machinery and devices where installation space is at a premium.

The performance advantages of the RSR/RSR N SERIES are a direct result of its meticulous engineering. The full-ball recirculation system ensures smooth, low-friction motion with high positional accuracy and excellent reproducibility. This translates into minimal stick-slip, a critical factor for applications requiring precise start-stop movements or fine incremental positioning. The guides are designed for high-speed operation with minimal vibration and noise, contributing to the overall efficiency and quiet performance of the host equipment. Furthermore, the series offers enhanced durability and a long service life, even under demanding operating conditions, reducing maintenance requirements and total cost of ownership. For ease of installation and alignment, many models incorporate features such as reference marks and a sealed design to prevent contamination from dust and debris, which is vital for maintaining precision in unclean environments.

Typical applications for the THK RSR/RSR N SERIES are found across industries where miniaturization, precision, and reliability are paramount. In industrial automation and machinery, these guides are integral components in compact CNC stages, precision assembly robots, pick-and-place units, and the linear axes of semiconductor and electronic component manufacturing equipment. Within the automotive sector, they are employed in advanced sensor testing apparatus, precision fuel injection system manufacturing jigs, and intricate automated inspection devices. The series is also ideally suited for precision equipment such as medical and diagnostic devices, including DNA analyzers and lab automation systems, optical and measuring instruments for coordinate measurement and microscopy, and sophisticated office automation equipment like high-speed scanners and printers. By offering a robust, miniature solution, the THK LM Guide RSR/RSR N SERIES enables designers and engineers to push the boundaries of miniaturization without compromising on the critical performance metrics of load capacity, accuracy, and smooth motion.

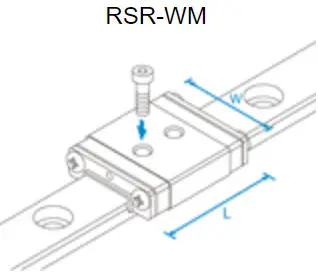

THK's LM Guide RSR, RSR WM, and SERIES represent the pinnacle of miniature linear motion technology, engineered for applications where space is at a premium but performance is non-negotiable. These full ball-type guides utilize a compact, high-rigidity design that delivers exceptional accuracy and smooth motion in a remarkably small footprint. The core of their performance lies in the patented THK ball circuit, which features a full-ball contact structure between the rail and block. This design ensures a large load capacity and high rigidity from all directions—radial, reverse-radial, and lateral. The balls circulate efficiently through precision-machined return guides, minimizing friction and enabling high-speed operation with minimal heat generation and excellent positional repeatability.

Key technical features that define these miniature models include their optimized ball groove geometry, which provides a high degree of contact for superior load distribution and long service life. The RSR WM SERIES, in particular, incorporates a sealed design with integrated wipers and seals that effectively prevent the ingress of contaminants like dust, chips, and moisture, making them exceptionally durable in harsh environments. All series are manufactured to exacting tolerances, ensuring low noise levels and consistent, smooth travel. Their compact cross-sections are achieved without sacrificing performance, allowing for direct integration into tight spaces within machinery and equipment.

The performance advantages of these LM Guides are substantial. They offer significantly reduced friction resistance compared to traditional sliding mechanisms, which translates into lower driving force requirements, higher efficiency, and improved energy savings. Their high rigidity ensures minimal deflection under load, maintaining precision even during high-speed reciprocating movements and under substantial moment loads. This results in improved machining accuracy, superior surface finishes in manufacturing processes, and enhanced overall equipment reliability. The long-term maintenance benefits are also notable; the sealed variants drastically extend relubrication intervals and protect against premature wear from abrasive particles.

Typical applications for the THK RSR, RSR WM, and SERIES are found across industries that demand precision and reliability in compact designs. In industrial machinery, they are integral to the function of high-speed pick-and-place robots, precision assembly machines, and the linear axes of compact CNC machining centers. Within the automotive sector, these guides are employed in precision testing equipment, automated welding systems, and small-scale robotic arms used on assembly lines. In the realm of precision equipment, they are the motion solution of choice for semiconductor manufacturing apparatus, medical device automation, precision measuring instruments, and optical positioning systems, where their accuracy, quiet operation, and compact size are critical to the application's success.

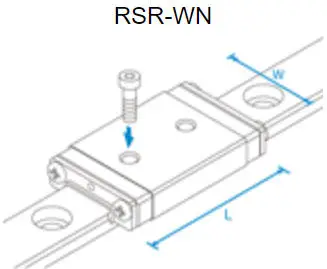

THK's LM Guide RSR/WN Series represents a compact yet high-performance linear motion solution engineered for applications where space constraints and precision are paramount. As a miniature full-ball type linear guide, this series incorporates four arc-grooved raceways arranged in a face-to-face configuration, creating an optimized load-bearing structure that delivers exceptional rigidity and smooth motion in minimal dimensions. The design features a unique ball circulation system where all balls undergo perfect recirculation through end caps, eliminating protrusions beyond the guide block and enabling seamless, uninterrupted travel even in confined layouts.

Technically, the RSR/WN Series stands out with its ability to handle multi-directional loads—radial, reverse-radial, and lateral—simultaneously, thanks to the 45° contact angle of the raceways. This angular contact design ensures high rigidity and precise positioning accuracy by minimizing elastic deformation under load. The compact steel-reinforced resin end caps not only facilitate smooth ball recirculation but also contribute to the series' lightweight construction and corrosion resistance when paired with optional stainless steel components. Pre-load adjustments are available to eliminate internal clearance, enhancing stiffness and reducing deflection during operation, which is critical for applications requiring high positional repeatability.

Performance advantages include low friction operation, achieved through the full-ball contact design and precision-ground raceways, resulting in minimal energy consumption and reduced heat generation. The series offers high-speed capability with minimal noise and vibration, making it suitable for dynamic applications. Its compact footprint allows for direct integration into tight spaces without compromising load capacity or travel accuracy. Maintenance is simplified due to the sealed design with integrated wipers and grease reservoirs, which protect the ball tracks from contaminants and extend service life even in harsh environments.

Typical applications span across industrial machinery, where the RSR/WN Series is deployed in precision assembly robots, semiconductor manufacturing equipment, and miniature linear actuators requiring high-speed positioning. In automotive systems, these guides are utilized in electronic throttle control mechanisms, sensor sliding units, and compact automation fixtures. For precision equipment, they serve critical roles in medical device positioning stages, optical instrument focusing systems, and laboratory automation modules where minimal size, high accuracy, and reliability are non-negotiable. The series' versatility also extends to packaging machinery, CNC tool changers, and measurement devices, demonstrating its adaptability across sectors demanding miniaturization without performance trade-offs.

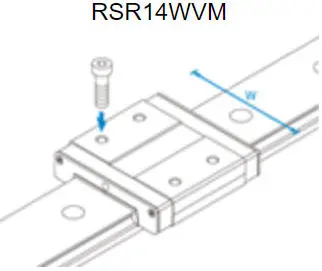

The THK LM Guide RSR14WVM SERIES represents a compact, high-precision linear motion solution engineered for applications where space constraints and demanding performance criteria converge. As a miniature, full ball-type LM guide, this model integrates a complete ball recirculation system within a remarkably small cross-section, delivering smooth, accurate linear travel with exceptional rigidity and longevity. Its design is optimized to provide reliable motion control in tight installations without sacrificing load capacity or operational stability.

Key technical features define the RSR14WVM's capability. The full ball-type contact mechanism ensures that the load is distributed across a maximum number of balls within the raceway, significantly increasing contact area and load capacity compared to designs with fewer points of contact. This configuration enhances moment load resistance and stiffness, critical for maintaining precision under complex force conditions. The compact dimensions of the RSR14WVM series make it ideal for miniaturized machinery, with a low profile that minimizes the required installation space. Precision-ground raceways and high-quality steel construction contribute to low friction, minimal noise, and vibration damping during operation. Additionally, the integrated seals effectively prevent contamination from dust, chips, and other particulates, preserving lubrication and extending service life even in challenging environments.

Performance advantages are evident in its operational efficiency and durability. The RSR14WVM exhibits high positional accuracy and repeatability, essential for processes requiring micron-level precision. Its robust construction allows for high-speed travel without compromising smoothness, reducing cycle times in automated systems. The guide’s resistance to wear and corrosion ensures long-term reliability, reducing maintenance frequency and total cost of ownership. Energy efficiency is another benefit, as the low friction coefficient minimizes power consumption for driving mechanisms.

Typical applications span multiple high-tech industries. In industrial machinery, the RSR14WVM is deployed in compact CNC machining centers, precision assembly robots, and semiconductor manufacturing equipment where precise linear movement in confined spaces is paramount. Within automotive systems, it facilitates accurate positioning in electronic throttle controls, sensor actuation mechanisms, and advanced driver-assistance system (ADAS) components. For precision equipment, this guide is integral to medical devices such as laboratory automation, diagnostic instruments, and surgical robots, as well as in optical alignment systems and measuring instruments that demand unwavering accuracy and minimal backlash. Its versatility and reliability make the THK RSR14WVM SERIES a cornerstone component in advancing automation and precision across modern engineering landscapes.