THK's LM Guide RSX WSM SERIES represents a significant advancement in miniature linear motion technology, specifically engineered to prevent ball fallout while maintaining high precision and reliability in compact applications. This full ball type LM Guide incorporates a unique retainer mechanism that securely holds the balls within the guide, even during disassembly or inverted installation, eliminating the risk of component loss and simplifying maintenance procedures. The design features a compact cross-section with optimized ball groove geometry, ensuring smooth motion and enhanced load capacity despite its miniature dimensions.

Key technical features include the use of high-carbon chromium bearing steel for all critical components, providing exceptional hardness and wear resistance. The RSX WSM SERIES employs THK's patented Caged Ball technology, where balls circulate smoothly through precisely machined pathways with minimal friction and heat generation. The guide rails undergo special heat treatment processes to achieve surface hardness of HRC 58-64, while the sliding blocks incorporate sealing units that effectively exclude contaminants and retain lubrication. The series offers various accuracy grades (Normal, High, and Precision) to match application requirements, with running parallelism maintained within strict tolerances.

Performance advantages are particularly notable in high-speed applications, where the RSX WSM SERIES demonstrates vibration damping characteristics and noise reduction up to 10dB compared to conventional designs. The anti-fallout feature ensures operational safety during rapid acceleration and deceleration cycles, with dynamic load ratings reaching 2.1 kN and static load capacities up to 3.4 kN depending on model size. The compact design achieves space savings of approximately 30% compared to standard miniature guides while maintaining comparable performance metrics. Service life calculations based on THK's fatigue theory predict operational lifetimes exceeding 10,000 km under normal loading conditions.

Typical applications span multiple industries where precision and reliability are paramount. In industrial automation, these guides are deployed in semiconductor manufacturing equipment for wafer handling robots, where their compact size enables higher density mounting of linear axes. The automotive industry utilizes them in precision assembly systems for electronic component placement and testing equipment requiring micron-level positioning accuracy. Medical device manufacturers incorporate RSX WSM guides in diagnostic imaging systems and laboratory automation where smooth, quiet operation is essential. Additional applications include precision measuring instruments, optical positioning systems, and compact CNC machinery where space constraints demand miniature solutions without performance compromise. The series' corrosion-resistant options make it suitable for cleanroom environments and applications requiring frequent sterilization cycles.

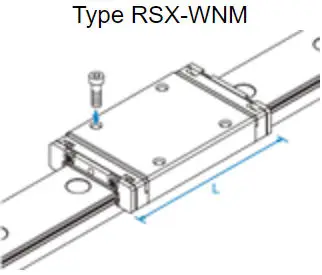

The THK LM Guide LM Guide (full ball type) with its innovative design prevents balls from falling out, making the Miniature LM Guide Model RSX Type RSX WNM SERIES exceptionally reliable for precision applications. This series incorporates a full ball-type recirculation system where balls are retained securely within the guide, even during disassembly or handling, eliminating the risk of misalignment or contamination. The compact, miniature profile of the RSX WNM models is engineered for space-constrained environments without sacrificing load capacity or rigidity. Key technical features include a high-rigidity, four-row circular arc groove design that provides balanced load distribution and smooth motion. The use of high-grade steel and advanced heat treatment processes ensures durability and resistance to wear, while precision grinding of raceways delivers low noise and vibration operation. Sealing options, such as integrated seals or scrapers, protect against dust and debris, enhancing longevity in harsh conditions.

Performance advantages of the RSX WNM SERIES are substantial, starting with its ability to maintain high accuracy and repeatability over extended periods. The full ball retention mechanism minimizes maintenance needs by preventing ball fallout during installation or transport, reducing downtime in automated systems. With low friction coefficients and optimized preload settings, these guides offer smooth, efficient linear motion that conserves energy and reduces heat generation. Their high-speed capability, combined with excellent shock resistance, makes them suitable for dynamic applications where rapid acceleration and deceleration are common. Additionally, the corrosion-resistant treatments available extend usability in environments exposed to moisture or chemicals, ensuring consistent performance in industries like food processing or medical equipment.

Typical applications span across industrial machinery, automotive systems, and precision equipment, where reliability and compactness are paramount. In industrial automation, the RSX WNM SERIES is ideal for CNC machine tools, robotic arms, and pick-and-place systems, providing precise positioning for milling, drilling, or assembly tasks. The automotive sector leverages these guides in engine component testing rigs, welding robots, and conveyor systems, where their shock absorption and high load capacity support heavy-duty operations. For precision equipment, such as semiconductor manufacturing devices, optical inspection instruments, or 3D printers, the miniature size and low particulate generation prevent contamination while enabling fine adjustments. Medical devices, including diagnostic scanners and laboratory automation, benefit from the smooth, quiet operation and hygiene-compliant designs. Overall, the THK RSX WNM SERIES delivers a robust solution for applications demanding miniaturization, durability, and uninterrupted performance in demanding environments.

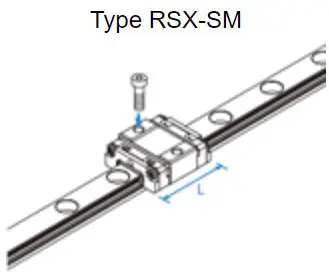

The THK LM Guide Model RSX SM SERIES represents a significant advancement in miniature linear motion technology, specifically engineered to address the critical challenge of ball retention in compact applications. This full ball type LM guide incorporates a patented design that prevents balls from falling out during handling or assembly, even when the rail and block are separated. This feature is particularly valuable in industries where precision components are frequently disassembled for maintenance or adjustment, eliminating the risk of lost components and ensuring consistent reassembly accuracy.

Technically, the RSX SM SERIES employs a unique ball circulation system with a reinforced end cap structure that securely retains the balls within the block. The full ball contact design provides four-directional equal load capacity, allowing the guide to handle radial, reverse-radial, and lateral loads simultaneously with high rigidity. These guides feature compact cross-sectional dimensions while maintaining high load capacities, with precision-ground raceways that deliver smooth, low-friction motion. The series is available in multiple accuracy classes (normal, high, and precision grades) to match application requirements, and all components undergo THK's specialized heat treatment processes for enhanced durability and wear resistance.

Performance advantages include exceptional positioning accuracy with repeatability within microns, low noise operation ideal for cleanroom environments, and maintenance-free operation thanks to effective sealing systems that prevent contamination. The anti-fallout ball design significantly reduces installation time and eliminates potential damage from mishandling. These guides demonstrate high stiffness-to-size ratios, vibration damping characteristics, and long service life even under high-frequency reciprocating motions.

Typical applications span multiple precision industries, including semiconductor manufacturing equipment where these guides position wafers with sub-micron accuracy, automotive assembly systems for precise component placement robots, medical device manufacturing for diagnostic equipment positioning stages, and optical instrument alignment systems. In automotive applications, they're deployed in electronic power steering mechanisms and transmission testing equipment. The miniature size makes them ideal for compact desktop manufacturing machines, PCB drilling and inspection systems, and laboratory automation equipment where space constraints demand maximum performance from minimal components. Their reliability and precision also make them suitable for aerospace instrumentation and packaging machinery requiring high-speed, accurate linear motion.

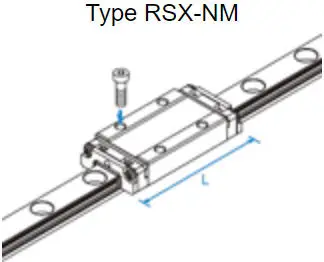

THK's LM Guide Model RSX Type RSX NM SERIES represents a significant advancement in miniature linear motion technology, specifically engineered to prevent ball fallout while maintaining high precision and reliability in compact applications. This full ball type LM guide incorporates a unique ball retainer mechanism that securely holds the balls within the guide, eliminating the risk of dislodgement during transportation, installation, or maintenance. The design ensures smooth, uninterrupted motion even in vertical or inverted orientations, making it ideal for space-constrained environments where traditional guides may fail.

Key technical features of the RSX NM SERIES include its compact cross-sectional dimensions, which allow for seamless integration into miniature assemblies without sacrificing load capacity or rigidity. The guide employs a high-precision, ground raceway with optimized ball groove geometry, reducing friction and minimizing torque variation for consistent performance. Its full ball contact design distributes loads evenly across all rolling elements, enhancing durability and extending service life under demanding conditions. The series also features corrosion-resistant materials and optional seals to protect against contaminants like dust and moisture, ensuring reliable operation in harsh industrial settings.

Performance advantages are evident in the RSX NM SERIES's ability to deliver high accuracy, low noise, and minimal maintenance requirements. The anti-fallout mechanism prevents operational disruptions, reducing downtime and increasing productivity in automated systems. With a high allowable load capacity and excellent positional repeatability, these guides support precise linear movements critical for applications requiring micron-level accuracy. Their lightweight yet robust construction contributes to energy efficiency by minimizing inertial losses in high-speed operations.

Typical applications span various industries, including industrial machinery where the RSX NM SERIES is used in CNC machining centers for tool positioning, semiconductor manufacturing equipment for wafer handling, and assembly robots for pick-and-place tasks. In automotive systems, these guides facilitate precise movements in engine component testing rigs, braking system calibrators, and electric vehicle battery production lines. For precision equipment, they are integral to medical devices like MRI scanners and surgical robots, optical alignment systems in metrology instruments, and 3D printing mechanisms requiring stable, repeatable motion. By combining anti-fallout reliability with miniature dimensions, the RSX NM SERIES enables innovation in compact, high-performance designs across diverse sectors.

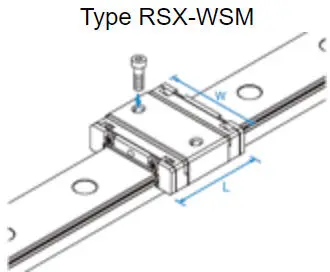

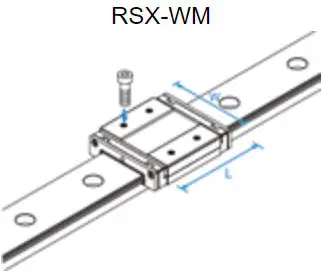

THK's LM Guide LM Guide (full ball type) with its anti-ball-dropout feature, specifically the Miniature LM Guide Model RSX within the RSX WM SERIES, represents a significant advancement in compact linear motion technology. This system is engineered to prevent the balls within the recirculating pathways from falling out, even when the rail and block are separated during maintenance or assembly. This is achieved through a uniquely designed retainer mechanism that securely holds the balls in place within the block, eliminating the risk of misplacement, contamination, or loss, which streamlines handling and reduces downtime in operational environments.

Technically, the RSX WM SERIES incorporates a full-ball contact design, where the load-bearing balls make complete contact with the raceways, distributing loads evenly and enhancing rigidity. The miniature profile is a standout feature, with compact dimensions that make it ideal for applications where space is at a premium. It maintains high precision with smooth, low-friction motion, thanks to precision-ground raceways and optimized ball circulation. The guide is constructed from high-carbon chromium bearing steel, heat-treated to achieve high hardness and wear resistance, ensuring long service life under demanding conditions. Sealing options are available to protect against dust, chips, and other contaminants, further boosting reliability in harsh environments.

Performance advantages include exceptional accuracy and repeatability, critical for precision positioning tasks. The anti-ball-dropout feature not only simplifies installation and maintenance but also reduces the risk of damage during handling, contributing to lower total cost of ownership. Its high rigidity allows it to withstand substantial loads—both radial and moment loads—while maintaining smooth operation at high speeds. The low noise and vibration characteristics make it suitable for quiet operation in sensitive settings. Additionally, the lubrication system is designed for efficiency, reducing the frequency of maintenance intervals and ensuring consistent performance over time.

Typical applications span across various high-demand sectors. In industrial machinery, the RSX WM SERIES is commonly used in CNC machining centers, pick-and-place robots, and automated assembly lines where precision and reliability are paramount. In automotive systems, it finds use in precision testing equipment, robotic welding arms, and engine component handling systems that require compact, robust linear guides. Within precision equipment, it is integral to medical devices like MRI scanners and laboratory automation, semiconductor manufacturing tools such as wafer handlers, and optical positioning systems where miniature size and anti-contamination features are critical. This versatility, combined with THK's reputation for durability, makes the RSX WM SERIES a preferred choice for engineers seeking efficient, space-saving linear motion solutions.

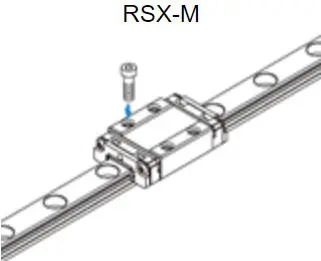

THK's LM Guide LM Guide (full ball type) with its innovative anti-ball-dropout design represents a significant advancement in linear motion technology, particularly in the compact RSX and RSX M SERIES of miniature guides. These precision components are engineered to prevent balls from falling out of the retainer even when the rail and block are separated, ensuring ease of handling during assembly and maintenance while maintaining the integrity of the recirculating ball system. This feature is critical in applications requiring frequent disassembly or where component separation is unavoidable, reducing the risk of contamination or misalignment.

The technical features of the RSX and RSX M SERIES include a compact, lightweight design ideal for space-constrained environments, with rail widths as narrow as 3mm in some models. They utilize a full ball-type recirculation system, where balls make complete contact with the raceways, distributing loads evenly and minimizing stress concentrations. The guides incorporate high-precision, hardened steel components for durability and corrosion resistance, often with optional seals to protect against dust and debris. Their low-friction design is enhanced by smooth ball recirculation, which reduces heat generation and wear over time. Additionally, the series offers various accuracy grades and preload options to match specific application requirements, from standard to high-precision scenarios.

Performance advantages stem from these features, delivering high rigidity, exceptional accuracy, and long service life even under demanding conditions. The anti-ball-dropout capability reduces downtime by simplifying installation and reducing the need for re-lubrication or ball replacement. With low noise and vibration operation, these guides ensure smooth, consistent motion, which is essential for high-speed applications. Their efficiency translates to energy savings and reduced maintenance costs, while the robust construction supports high load capacities, including moment loads, without sacrificing precision.

Typical applications span across industrial machinery, automotive systems, and precision equipment where reliability and compactness are paramount. In industrial automation, they are used in CNC machines, robotic arms, and pick-and-place systems for precise positioning and repeatability. The automotive industry leverages them in assembly lines, testing equipment, and engine component guides where high loads and harsh environments are common. For precision equipment, such as medical devices, semiconductor manufacturing tools, and optical instruments, the RSX and RSX M SERIES provide the stability and accuracy needed for micron-level movements. Their miniature size makes them suitable for small-scale automation, laboratory apparatus, and electronic manufacturing, ensuring optimal performance in tight spaces without compromising on durability or ease of use.