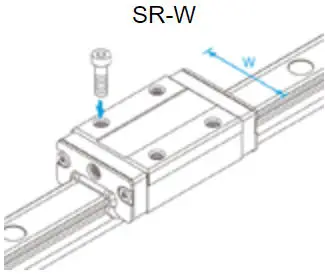

The THK LM Guide SR and SRW Series represent a significant advancement in linear motion technology, featuring a full-ball type, radial design engineered for exceptional rigidity and precision. These guides utilize a unique Gothic arch groove geometry in both the rail and block, creating a highly stable, two-point contact for each ball. This configuration allows the SR Series to handle substantial loads from all directions—radial, reverse-radial, and lateral—with remarkable accuracy and minimal deformation. The SRW variant incorporates a wider block, further enhancing its moment load capacity and overall stability, making it particularly suitable for applications demanding superior stiffness under complex force conditions.

Key technical features define the performance envelope of these components. The full-ball type recirculation system ensures smooth, consistent motion by maximizing the number of load-bearing balls in contact. This design minimizes friction and distributes stress evenly, significantly extending service life. Preload options are available, allowing for precise adjustment to eliminate internal clearance, which is critical for applications requiring high positional accuracy and repeatability. The seals and scrapers integrated into the block are highly effective at excluding contaminants like dust and chips while retaining lubrication, ensuring reliable operation even in harsh industrial environments. This robust sealing system dramatically reduces maintenance intervals and protects the precision-ground components from premature wear.

Performance advantages are immediately apparent in demanding operational scenarios. The high rigidity of the SR and SRW Series directly translates to reduced vibration and deflection during high-speed traversal or heavy cutting operations, enabling improved surface finishes on machined parts and protecting sensitive tooling. Their low friction coefficient contributes to high efficiency, allowing for the use of smaller, more energy-efficient drive motors and reducing overall system power consumption. The design’s inherent accuracy and smooth motion profile are essential for minimizing settling times and following error in closed-loop systems, leading to higher throughput and improved product quality.

Typical applications for these robust linear guides span across critical sectors of modern manufacturing. In industrial machinery, they are the backbone of high-speed machining centers, CNC lathes, and grinding machines, where their rigidity ensures dimensional accuracy in fabricated components. Within the automotive industry, they are deployed in precision assembly robots, automated welding systems, and high-speed transfer lines, enduring constant, rapid cycles with unwavering reliability. The series also finds extensive use in precision equipment such as semiconductor manufacturing apparatus, coordinate measuring machines (CMMs), and medical device automation, where their cleanliness, smooth motion, and sub-micron level precision are non-negotiable for successful operation. The THK LM Guide SR and SRW Series thus provide a foundational motion solution that combines high load capacity, enduring accuracy, and long-term reliability for the most challenging automation and precision engineering tasks.

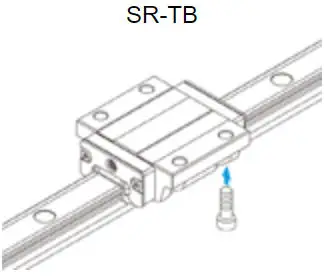

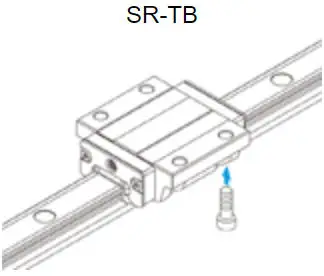

THK's LM Guide SR/SR TB Series represents a full ball type radial linear motion system engineered for high rigidity and precision across demanding industrial applications. This robust guide mechanism incorporates a unique radial ball arrangement where the load-bearing balls are positioned perpendicular to the direction of motion, creating a highly stable and rigid structure capable of withstanding substantial loads from all directions—radial, reverse-radial, and lateral. The series features a compact, low-profile design that maximizes space efficiency in machinery layouts while maintaining exceptional load capacity and moment resistance.

Key technical features include THK's advanced ball circulation system, which ensures smooth, consistent motion by efficiently recirculating balls through the carriage. The SR/SR TB Series incorporates precision-ground raceways and high-grade steel balls for minimal friction, reduced wear, and extended service life. Special sealing mechanisms protect against contaminants like dust, chips, and moisture, making these guides suitable for harsh operating environments. The TB variant includes a built-in taper lock mechanism for simplified installation and enhanced mounting accuracy, eliminating the need for complex alignment procedures during assembly.

Performance advantages are significant across multiple metrics. The radial ball configuration delivers superior rigidity, minimizing deflection under load and enabling higher positioning accuracy with repeatability within micrometers. This structural stability translates to reduced vibration and quieter operation at high speeds, contributing to improved machining quality and surface finishes in manufacturing processes. The low-friction design results in smooth motion characteristics with consistent dynamic behavior, allowing for higher acceleration rates and reduced settling times in rapid cycling applications. Maintenance requirements are minimal due to the efficient sealing and long-term lubrication retention, while the standardized mounting dimensions facilitate easy replacement and interchangeability.

Typical applications span critical sectors where precision linear motion is essential. In industrial machinery, SR/SR TB Guides are deployed in CNC machining centers for tool changer systems, spindle supports, and workpiece positioning tables, where their rigidity ensures machining accuracy and surface quality. Automotive manufacturing systems utilize these guides in robotic welding arms, automated assembly stations, and precision testing equipment requiring reliable motion under continuous operation. Semiconductor and electronics production equipment incorporate them in wafer handling robots, inspection stages, and PCB assembly machines where cleanroom compatibility and micron-level precision are mandatory. Additional applications include medical device manufacturing equipment, optical positioning systems, and packaging machinery where smooth, precise linear motion directly impacts product quality and production efficiency.

THK's LM Guide SR/SR T Series represents a full ball type radial linear motion system engineered for demanding industrial applications requiring high rigidity, precision, and longevity. This series utilizes a unique radial load-bearing design where the load-carrying ball grooves are precisely ground into both the rail and the slider in a Gothic arch configuration. This geometry ensures optimal contact between the balls and the raceways, distributing loads evenly and providing exceptional stability. The full ball complement design maximizes the number of recirculating balls within the system, significantly increasing load capacity and stiffness compared to standard designs. The SR T variant incorporates a built-in seal plate with specialized contact seals that effectively exclude contaminants like dust, chips, and moisture, while also retaining grease for extended lubrication intervals, making it particularly suited for harsh environments.

Key technical features of the SR/SR T SERIES include its four-row, two-arc groove construction, which provides equal load capacity in all radial directions—radial, reverse radial, and lateral. This balanced design allows the guide to handle complex combined loads and overturning moments with minimal deformation. The high-rigidity slider body, combined with the large number of load-carrying balls, results in a very high static and dynamic load rating. Precision grinding of all critical surfaces ensures smooth, low-friction motion with high positional accuracy and excellent repeatability. The recirculation system is designed for smooth ball flow, minimizing vibration and noise during operation, even at high speeds.

The performance advantages are substantial. The high rigidity directly translates to improved machining accuracy in equipment by minimizing deflection under load, which is critical for maintaining tight tolerances. The increased load capacity allows for the downsizing of components or enables machinery to handle heavier workloads without compromising service life. Its low friction characteristics contribute to higher efficiency, requiring less drive force and reducing energy consumption. The robust construction and effective sealing in the SR T model lead to dramatically extended maintenance cycles and superior reliability, reducing total cost of ownership over the system's lifespan.

Typical applications for the SR/SR T LM Guide are found across a wide spectrum of precision industries. In industrial machinery, they are indispensable in high-speed machining centers, CNC lathes, grinding machines, and electric discharge machines (EDMs) where they provide the stable and precise linear motion for tool posts, slides, and tables. Within automotive manufacturing systems, these guides are employed in robotic welding arms, precision assembly robots, transfer lines, and automated inspection equipment. In the realm of precision equipment, they facilitate accurate motion in semiconductor manufacturing apparatus like steppers and bonders, as well as in precision measuring instruments, optical positioning systems, and various automated laboratory equipment where smooth, vibration-free, and highly reliable linear guidance is a fundamental requirement.

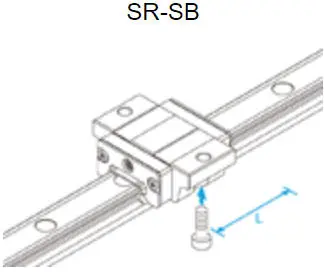

THK's LM Guide SR, SR SB, and SERIES represent a class of radial-type linear motion guides utilizing a full-ball contact design, engineered to deliver exceptional precision, rigidity, and longevity in demanding automation and machinery applications. These guides are characterized by their robust construction, where a circulating ball bearing system operates within a Gothic arch groove raceway. This specific geometry ensures that load-bearing balls make contact at four distinct points, effectively doubling the load capacity compared to standard two-point contact designs. The result is a highly rigid linear motion system capable of withstanding substantial loads from all directions—radial, reverse-radial, and lateral—while maintaining smooth, low-friction movement.

Key technical features of these radial-type LM Guides include their optimized ball circulation system, which minimizes resistance and prevents ball-to-ball contact, significantly reducing noise, vibration, and heat generation during operation. The incorporation of high-grade steel components, subjected to THK's proprietary heat treatment processes, ensures superior surface hardness and wear resistance. Many models within these series are available with integrated seals or scrapers to effectively exclude contaminants like dust, chips, and moisture, thereby protecting the precision rolling elements and extending service life even in harsh industrial environments. The compact, low-profile design of the SR and related series allows for space-saving integration into machinery with limited mounting real estate, without compromising on performance or load-bearing capability.

The performance advantages are substantial. The full-ball type design provides a higher load rating and greater static permissible moment, enabling these guides to handle complex multi-directional forces encountered in applications with significant overhanging loads or moment stresses. This inherent rigidity translates into improved positioning accuracy, repeatability, and reduced deflection under load, which is critical for maintaining machining tolerances or assembly precision. The low friction coefficient contributes to high-speed capability and excellent motion smoothness, reducing the power required from drive motors and leading to overall energy efficiency. Their durability and long maintenance intervals ensure high machine uptime and reduced total cost of ownership.

Typical applications for the THK LM Guide Radial Type SR, SR SB, and SERIES are found across a wide spectrum of industries. In industrial machinery, they are indispensable in high-precision machine tools for axes movement, such as in CNC machining centers, grinding machines, and electrical discharge machining (EDM) equipment. Within the automotive manufacturing sector, they are deployed in automated assembly lines, robotic welding arms, precision parts handling systems, and high-speed pick-and-place units. For precision equipment, these guides are integral to the functioning of semiconductor manufacturing apparatus, including wafer steppers and inspection machines, optical positioning stages, and various types of measuring and testing instruments where unwavering accuracy and reliability are non-negotiable.

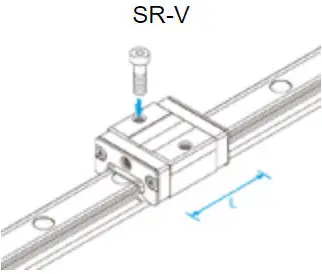

The THK LM Guide SR and SRV Series represent a full ball type radial linear motion system engineered for high rigidity and precision in demanding industrial applications. These guides utilize a unique circular-arc groove design in both the rail and block, creating a contact angle optimized for radial load support while maintaining smooth motion characteristics. The full ball complement configuration maximizes load capacity by ensuring continuous ball-to-raceway contact along the entire circuit, distributing forces evenly across all rolling elements. This design significantly enhances moment load resistance compared to standard linear guides, making the SR/SRV Series particularly suitable for applications requiring stability under complex force conditions.

Key technical features include the incorporation of THK's patented Caged Ball technology in select SRV models, where polymer retainers separate individual balls to eliminate metal-to-metal contact. This innovation drastically reduces noise levels during operation and minimizes heat generation at high speeds, while preventing ball crowding for consistent lubrication distribution. The series offers preload options from light to heavy, allowing precise adjustment of rigidity and backlash control based on application requirements. Corrosion-resistant variants with stainless steel rails and blocks or specialized surface treatments are available for harsh environments involving exposure to coolants, chemicals, or washdown procedures.

Performance advantages manifest in multiple dimensions of operational efficiency. The optimized recirculation system ensures smooth ball movement even at accelerated speeds up to 3 m/s, with velocity coefficients significantly higher than conventional designs. Load capacities exceed comparable models by 15-30% depending on size selection, with static load ratings reaching 147 kN in larger configurations. The rigid structure provides exceptional accuracy with running parallelism maintained within 7 μm per meter of travel, while the enhanced sealing system incorporating multi-layer contact seals and metal scrapers effectively excludes contaminants exceeding IP65 equivalence.

In industrial machinery contexts, these guides serve as critical components in CNC machining centers where they support spindle movement under heavy cutting forces, in injection molding machines facilitating precise mold opening/closing sequences, and in automated assembly systems requiring repetitive positioning accuracy. Automotive manufacturing implementations include robotic welding arms requiring rigidity for consistent weld quality, precision transfer lines moving engine components between stations, and brake disk machining equipment demanding vibration damping characteristics. Precision equipment applications encompass semiconductor wafer handling robots needing cleanroom compatibility, medical device assembly systems requiring smooth ultra-low speed operation, and coordinate measuring machines where minimal friction variation ensures measurement repeatability. The SR/SRV Series' combination of high load capacity, corrosion resistance options, and precision tracking makes it particularly valuable in applications where reliability directly impacts production quality and equipment longevity.