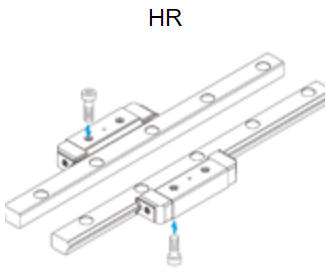

THK's HR Series LM Guide represents a pinnacle of linear motion engineering, featuring a full-ball type, four-way equal load design that delivers exceptional rigidity, precision, and longevity in demanding applications. This "separate" type guide is characterized by its construction where the rail and block can be disassembled, facilitating easier maintenance, inspection, and replacement of components without requiring the entire system to be dismantled from the machinery. The core of its performance lies in the "full ball" recirculation system. Unlike designs with fewer contact points, the HR Series incorporates a full complement of balls within the load-bearing raceways, maximizing the contact area between the balls and the raceway grooves. This configuration significantly increases load capacity and rigidity.

The defining technical feature is the "four-way equal load" design. This means the LM block is engineered to handle loads of identical magnitude from all four primary directions: radial, reverse radial, and lateral in both orientations. This is achieved through a symmetrical Gothic arch groove geometry in the raceways. This balanced construction ensures stable motion and high-precision guidance even when subjected to complex, multi-directional forces and overturning moments. The result is a linear guide with exceptionally high rigidity and an ability to maintain accuracy under challenging conditions that would cause deflection or wear in less robust designs.

Performance advantages are substantial. The high rigidity translates directly into improved machining and positioning accuracy, as the system resists deformation under load. The large number of balls and optimized contact angles distribute the load more evenly, leading to a dramatically longer service life and enhanced fatigue resistance. The separate type construction offers unparalleled practical benefits for maintenance. Worn or damaged blocks can be swapped out on-site with minimal downtime, and the system can be easily re-lubricated to ensure consistent performance over its long operational life. This design also simplifies initial installation and alignment procedures.

Typical applications for the HR Series LM Guide are found wherever heavy loads, high precision, and unwavering reliability are non-negotiable. In industrial machinery, it is the preferred choice for the critical axes of heavy-duty machining centers, high-precision grinders, and large-scale transfer lines where resisting cutting forces and maintaining positional integrity is paramount. Within automotive manufacturing systems, these guides are integral to robust welding robots, heavy-duty assembly pallets, and precise stamping press feeders. In the realm of precision equipment, the HR Series provides the stable foundation required for semiconductor manufacturing apparatus, precision measuring instruments, and inspection machines, where even micron-level deflections are unacceptable. Its combination of high load capacity, exceptional rigidity, and service-friendly design makes it an indispensable component for advancing automation and precision in modern industry.

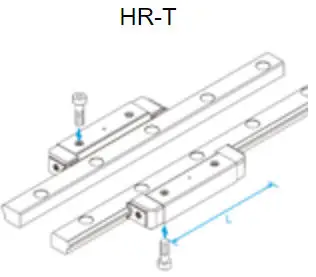

THK's LM Guide HR T SERIES represents a pinnacle in linear motion technology, engineered for applications demanding exceptional rigidity, precision, and longevity under substantial loads. This full ball type, separate four-way equal load ball LM guide is meticulously designed to manage loads uniformly in all four primary directions: radial, reverse-radial, and lateral. The core of its design is the utilization of a full ball complement within the ball rolling grooves, which maximizes the number of load-bearing balls. This configuration significantly enhances load capacity and rigidity compared to standard designs, directly translating to superior performance in high-demand scenarios.

Key technical features define the HR T SERIES's operational excellence. The "separate" type construction allows for independent handling of the rail and block, simplifying installation, maintenance, and replacement procedures. The "four-way equal load" characteristic is achieved through a optimized Gothic arch groove design, ensuring that load capacity and rigidity are consistent whether the force is applied from above, below, or from the sides. This symmetry is crucial for maintaining precision under complex and multi-directional loading conditions. Furthermore, the high-rigidity, high-capacity design incorporates advanced sealing systems to effectively shield the ball rolling paths from contaminants like dust, chips, and moisture, while also ensuring optimal grease retention for long-term, maintenance-free operation. The precision-ground rolling surfaces guarantee smooth, low-friction motion with minimal running noise and excellent positional accuracy.

The performance advantages of the HR T SERIES are substantial. Its high static and dynamic load ratings allow machinery to handle heavier workpieces or exert greater force without compromising guide life or accuracy. The exceptional rigidity minimizes elastic deformation under load, which is critical for achieving and maintaining high positioning precision in machining and assembly processes. This robustness, combined with the protective seals, results in an extended service life and reliable operation even in harsh industrial environments with significant particulate or liquid exposure. The design inherently contributes to smoother motion, reduced vibration, and higher permissible operating speeds, enhancing the overall efficiency and throughput of the equipment it integrates into.

Typical applications for the THK LM Guide HR T SERIES are found wherever heavy loads, high precision, and unwavering reliability are non-negotiable. In industrial machinery, it is indispensable for the vertical axes of heavy-duty machining centers, high-precision grinding machines, and the robust linear axes of injection molding machines. Within automotive manufacturing systems, these guides are deployed in critical automation equipment such as heavy-duty robotic transfer lines, precision welding robots, and large assembly jigs. For precision equipment, the HR T SERIES provides the stable and rigid foundation required for high-accuracy coordinate measuring machines (CMMs), semiconductor manufacturing equipment like steppers and wafer handlers, and various high-performance industrial automation platforms where consistent, repeatable motion is paramount to the process.