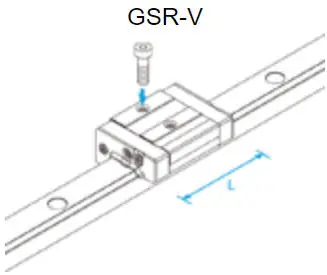

The THK LM Guide GSR V SERIES represents a high-performance linear motion solution engineered for applications demanding exceptional radial rigidity and precision under complex load conditions. As a full ball type, separate radial configuration, this guide system features a unique design where the rail and block can be disassembled and reassembled, facilitating straightforward installation, maintenance, and replacement in constrained or intricate machinery layouts. The core of its performance lies in the optimized ball circulation system, which ensures smooth, consistent motion with minimal friction and high positional accuracy.

Key technical features of the GSR V SERIES include its four-row, circular-arc groove design that provides simultaneous contact points between the balls and raceways. This configuration significantly enhances load capacity and moment rigidity, particularly in the radial direction, making it resilient against overturning forces and vibration. The incorporation of THK's advanced Caged Ball technology in some variants minimizes friction and heat generation by preventing ball-to-ball contact, thereby extending service life and maintaining lubrication efficiency. Precision-ground raceways and high-grade steel construction contribute to its durability and corrosion resistance, while optional seals and wipers protect against contaminants like dust, chips, and moisture in harsh environments.

Performance advantages of this series are evident in its ability to sustain high speeds and accelerations with minimal noise and vibration, ensuring operational stability in dynamic applications. The separate radial type design allows for easy preload adjustment, enabling users to fine-tune rigidity and backlash to match specific requirements, which is critical for maintaining accuracy over long-term use. Its high stiffness-to-weight ratio supports heavy loads without compromising precision, reducing deflection and improving repeatability in positioning tasks. Additionally, the low coefficient of friction enhances energy efficiency, contributing to lower power consumption and reduced operational costs.

Typical applications span across industries where reliability and precision are paramount. In industrial machinery, the GSR V SERIES is deployed in CNC machining centers, grinding machines, and automated assembly systems for precise tool positioning and workpiece handling. Within automotive systems, it supports robotics for welding and painting, as well as testing equipment that requires robust performance under cyclic loads. In precision equipment, it finds use in semiconductor manufacturing devices, medical imaging systems, and optical alignment apparatuses, where smooth, vibration-free motion is essential for achieving micron-level accuracy. This versatility, combined with THK's reputation for quality, makes the GSR V SERIES a trusted component in advancing automation and technological innovation.

The THK LM Guide GSR T SERIES represents a specialized linear motion solution engineered for applications requiring high rigidity, precision, and durability under demanding conditions. As a full ball type, separate (radial type) LM guide, this model features a unique design where the rail and block can be disassembled, facilitating easier installation, maintenance, and replacement in complex machinery setups. The GSR T SERIES incorporates a radial load-bearing configuration, optimizing it for handling forces perpendicular to the direction of motion, which is critical in applications with significant vertical or horizontal loads.

Key technical features of the GSR T SERIES include a full ball recirculation system, where balls circulate smoothly through the block and rail interface, ensuring consistent contact and minimal friction. This design enhances load distribution, reducing wear and extending service life. The guide is constructed from high-carbon chromium bearing steel, hardened and precision-ground to achieve tight tolerances and superior surface finish. It offers high rigidity due to its robust structure and four-row circular arc groove design, which increases contact area between the balls and raceways. Additionally, the separate type allows for preload adjustment, enabling customization of stiffness and backlash control to suit specific operational requirements. Sealing systems, such as scrapers and end seals, are integrated to protect against contaminants like dust and chips, making it suitable for harsh environments.

Performance advantages of the GSR T SERIES are notable in its ability to deliver smooth, low-friction linear motion with high positional accuracy and repeatability. The full ball type design minimizes vibration and noise, contributing to quieter operation and improved machine performance. Its high load capacity, combined with excellent resistance to shock and vibration, ensures reliability in high-speed applications. The separate nature of the components simplifies assembly and alignment, reducing downtime during installation or servicing. Moreover, the guide's corrosion-resistant options and lubrication retention features enhance longevity, even in exposed or variable temperature conditions.

Typical applications span across industrial machinery, automotive systems, and precision equipment. In industrial automation, the GSR T SERIES is commonly used in CNC machine tools, machining centers, and robotic arms, where precise linear guidance is essential for cutting, milling, or positioning tasks. Within the automotive sector, it finds use in assembly lines, welding robots, and testing equipment, providing stable motion under heavy loads and repetitive cycles. For precision instruments, such as semiconductor manufacturing devices, medical imaging systems, or optical alignment equipment, this LM guide ensures minimal deflection and high accuracy, supporting critical processes that demand micron-level precision. Overall, the THK LM Guide GSR T SERIES offers a versatile, high-performance solution for engineers seeking to optimize linear motion systems in diverse, challenging environments.

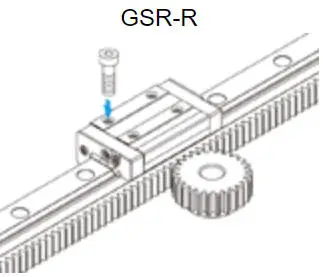

The THK LM Guide GSR R Series represents a specialized linear motion solution engineered for applications requiring precise radial load handling and independent rail/slider configuration. This full ball type LM Guide employs a unique separate (radial type) design where the rail and block can be mounted independently, offering exceptional installation flexibility and compensation for mounting surface inaccuracies. Characterized by its four-point contact ball groove design, the GSR R Series maintains smooth motion characteristics while providing high rigidity and excellent vibration damping properties.

Technical features include a precision-ground raceway structure that ensures consistent ball recirculation and minimal friction resistance. The full ball complement design maximizes load distribution across all contact points, significantly enhancing load capacity compared to standard designs. Each component undergoes micro-smoothing treatment to reduce surface roughness, resulting in quieter operation and extended service life. The series incorporates THK's patented Caged Ball technology in select models, which prevents ball-to-ball contact and reduces heat generation during high-speed operation. Standard configurations include multiple sealing options with integrated wipers and grease reservoirs to maintain lubrication integrity in contaminated environments.

Performance advantages manifest in several critical areas. The radial-type configuration delivers superior moment load resistance, particularly effective against overturning moments encountered in cantilevered applications. With accuracy grades ranging from standard to precision levels, the GSR R Series achieves positioning repeatability within microns, making it suitable for precision positioning applications. The independent mounting system allows for simplified alignment procedures and accommodates minor mounting surface imperfections without compromising performance. Dynamic load ratings exceed conventional designs by 15-20% while maintaining compact cross-sectional dimensions, enabling space-optimized machine designs.

Industrial machinery applications prominently feature the GSR R Series in precision grinding machines, where its vibration damping characteristics improve surface finish quality, and in semiconductor manufacturing equipment requiring micron-level positioning stability. Automotive production systems utilize these guides in robotic welding arms that demand high moment load capacity and in automated assembly lines where repeated positioning accuracy is paramount. Precision equipment implementations include coordinate measuring machines benefiting from the low friction characteristics, and medical imaging systems where smooth, quiet operation is essential. The series particularly excels in vertical mounting orientations common in Z-axis applications, where its enhanced moment rigidity prevents deflection under gravitational loads.

Maintenance considerations are minimized through the integrated sealing systems that effectively exclude contaminants while retaining lubrication. The separable design facilitates replacement of individual components without requiring complete system disassembly, significantly reducing downtime during maintenance operations. Compatible with various lubrication options including grease and oil systems, the GSR R Series maintains performance across temperature ranges from -15°C to 80°C, ensuring reliability in diverse operating environments.