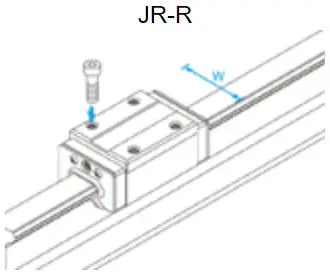

THK's LM Guide JR R Series represents a full ball type linear motion system engineered for high rigidity and precision in demanding industrial applications. This structural member rail system features a unique four-row circular arc groove design with a 45-degree contact angle, creating optimized load distribution across all directions. The JR R Series incorporates THK's patented double-lip seal system with a specialized grease reservoir that provides exceptional contamination protection while maintaining smooth motion characteristics. Each guide features precision-ground raceways and balls manufactured to JIS Class 5 tolerance standards, ensuring consistent performance and extended service life under rigorous operating conditions.

Technical innovations distinguish the JR R Series with its enhanced structural integrity and load capacity. The rail's cross-sectional geometry has been optimized to provide approximately 15% higher moment rigidity compared to conventional designs, significantly reducing deflection under complex loading scenarios. The full ball configuration ensures uniform stress distribution across all contact points, while the specially engineered ball recirculation system minimizes noise generation during high-speed operation. Preloaded options are available in light, medium, and heavy configurations, allowing for precise stiffness tuning according to application requirements. The system's corrosion-resistant surface treatment and integrated lubrication channels further contribute to maintenance-free operation in challenging environments.

Performance advantages manifest in multiple operational parameters, including exceptional positional accuracy with repeatability within microns, vibration damping characteristics that improve machining quality, and thermal stability that maintains precision across temperature variations. The JR R Series demonstrates superior resistance to edge loading and impact forces, with dynamic load ratings reaching up to 49.5 kN and static load capacities to 92.1 kN depending on model size. Energy efficiency is achieved through low friction coefficients (typically μ=0.002-0.003), reducing power consumption in automated systems. The design's compact profile maximizes usable machine space while providing full ball contact that distributes loads more effectively than competitive point-contact systems.

Typical applications span industrial automation, where these guides provide precise positioning for CNC machining centers, semiconductor manufacturing equipment, and electronic component assembly lines. In automotive manufacturing, JR R Series guides ensure accuracy in robotic welding arms, transfer line systems, and engine component machining fixtures. The system's vibration resistance makes it ideal for precision measurement instruments, optical positioning stages, and medical device manufacturing equipment. Additional implementations include packaging machinery requiring high-speed linear motion, automated warehouse retrieval systems, and precision inspection apparatus where minimal deflection under load is critical. The combination of high rigidity, precision, and durability makes the JR R Series particularly suitable for applications demanding long-term accuracy with minimal maintenance intervention across 24/7 production environments.

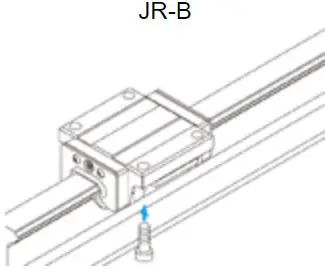

The THK LM Guide JR B SERIES represents a full ball type linear motion system engineered for high rigidity and precision in demanding industrial applications. This structural member rail system incorporates a unique design where the rail itself functions as a structural component of the machine, eliminating the need for separate mounting bases and significantly enhancing overall system stiffness. The JR B SERIES features a compact, low-profile design with a reinforced rail structure that provides exceptional load capacity and moment resistance. Its full ball-type recirculation system ensures smooth, nearly frictionless motion by maintaining continuous ball contact between the rail and block, which minimizes rolling resistance and enables high-speed operation with minimal heat generation.

Key technical features include the use of large-diameter balls arranged in a 4-row, circular arc groove configuration that optimizes load distribution. The series incorporates THK's advanced Caged Ball technology in some models, which separates individual balls with a resin cage to prevent metal-to-metal contact, reducing noise, wear, and the need for frequent relubrication. The precision-ground raceways maintain consistent accuracy throughout the system's lifespan, while special sealing systems with multiple contact seals and metal scrapers effectively exclude contaminants even in harsh environments. These guides are available in various accuracy grades (Normal, High, and Super High) to match specific application requirements.

Performance advantages of the JR B SERIES include exceptional positioning accuracy with repeatability within microns, high rigidity that minimizes deflection under load, and maintenance-free operation in many configurations. The structural member design allows for significant weight reduction in machine frameworks while maintaining or even improving stiffness compared to conventional designs. These guides demonstrate excellent vibration damping characteristics and maintain stable performance across wide temperature ranges. Their efficient sealing systems provide reliable protection against dust, chips, and other particulate matter, ensuring long service life even in contaminated environments.

In industrial machinery applications, the JR B SERIES is extensively used in machining centers, CNC equipment, industrial robots, and automated assembly systems where high precision and rigidity are critical. The automotive industry employs these guides in welding robots, transfer lines, and precision testing equipment requiring reliable performance under continuous operation. Within precision equipment sectors, they find application in semiconductor manufacturing equipment, medical devices, optical instruments, and measuring machines where smooth, accurate linear motion is essential. The series' structural member capability makes it particularly suitable for gantry systems, large-scale positioning equipment, and applications where minimizing machine footprint while maximizing performance is paramount.

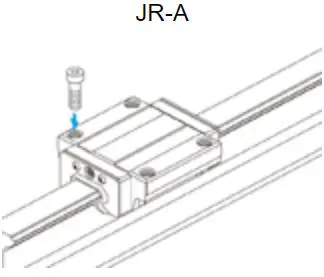

The THK LM Guide JR A SERIES represents a full ball type linear motion system engineered for high rigidity, precision, and durability in demanding industrial applications. This structural member rail model integrates a robust rail and block assembly where recirculating balls provide smooth, low-friction motion along the entire travel path. The JR A SERIES features a compact design with a high load capacity, achieved through THK’s patented ball circulation system that ensures even distribution of forces and minimal wear over time. Key technical attributes include four rows of balls arranged in a Gothic arch groove configuration, which enhances contact rigidity and allows for simultaneous load handling in all directions—radial, reverse radial, and lateral. The rail is manufactured from high-carbon chromium bearing steel, hardened to HRC 58–62, and ground to precise tolerances, ensuring consistent performance under heavy loads and high-speed operations. Sealing systems, including scrapers and end seals, protect the ball circuits from contaminants like dust, chips, and moisture, extending service life in harsh environments.

Performance advantages of the JR A SERIES LM Guide are evident in its ability to deliver exceptional accuracy, reduced friction coefficients, and minimal maintenance requirements. The full ball contact design distributes loads evenly across the rolling elements, reducing stress concentrations and enabling higher permissible loads compared to conventional designs. This results in improved positional accuracy, with running parallelism errors minimized to within microns, making it ideal for applications requiring repeatable linear motion. The low friction characteristics contribute to energy efficiency, as driving forces are reduced, and heat generation is minimized during high-cycle operations. Additionally, the JR A SERIES supports preload adjustments, allowing for customization to eliminate backlash and enhance stiffness in precision setups. Its corrosion-resistant options, such as stainless steel components or surface treatments, further broaden its suitability for cleanrooms or corrosive atmospheres.

Typical applications span across industrial machinery, automotive systems, and precision equipment where reliability and precision are critical. In industrial automation, the JR A SERIES is deployed in CNC machining centers, robotic arms, and transfer lines, providing stable guidance for cutting tools and workpiece positioning. The automotive industry utilizes these guides in welding robots, assembly jigs, and testing equipment, where high load capacity and resistance to vibration are essential. For precision instruments, such as semiconductor manufacturing tools, medical imaging devices, or optical alignment systems, the JR A SERIES ensures smooth, jitter-free motion critical to micron-level accuracies. Its adaptability to various mounting orientations and environments—from high-temperature manufacturing cells to sterile laboratories—underscores its versatility. By combining advanced materials, precision engineering, and thoughtful design, the THK LM Guide JR A SERIES delivers a solution that optimizes performance, reduces downtime, and supports innovation in modern machinery and equipment.