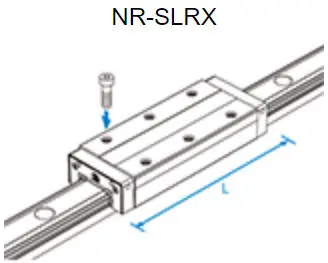

The THK LM Guide NR X NR SLRX SERIES represents a significant advancement in linear motion technology, specifically engineered to handle ultra-heavy loads with exceptional stability and precision. This full ball type, radial design LM Guide incorporates a unique structural configuration where the load-bearing balls are arranged in a radial pattern, maximizing contact area and distributing forces evenly across the guideway. This design is optimized for applications requiring robust support under extreme vertical and horizontal loads, ensuring minimal deformation and maintaining alignment even in the most demanding operational environments. The series features a reinforced steel construction with precision-ground raceways, providing high rigidity and resistance to shock and vibration, which is critical for maintaining accuracy over long service life.

Key technical features of the NR X NR SLRX SERIES include its high load capacity, achieved through a full complement of balls that eliminate retainer-related limitations, allowing for smoother motion and reduced friction. The radial type configuration enhances moment load resistance, making it ideal for applications with significant off-center forces. Additionally, the guide incorporates THK's proprietary surface treatment and lubrication systems, which reduce wear and extend maintenance intervals. Performance advantages are evident in its ability to sustain high-speed operation without sacrificing precision, thanks to optimized ball circulation that minimizes heat generation and noise. The low friction coefficient ensures energy efficiency, while the sealed design protects against contaminants like dust and moisture, making it suitable for harsh industrial settings.

In industrial machinery, the NR X NR SLRX SERIES is commonly deployed in heavy-duty CNC machining centers, large-scale transfer systems, and press machines where high load-bearing capacity and positional accuracy are paramount. Its durability and precision reduce downtime and enhance productivity in automated production lines. In automotive systems, this LM Guide is utilized in robotic welding arms, assembly line conveyors, and testing equipment that handle heavy components, such as engine blocks or chassis parts, ensuring reliable performance under repetitive stress. For precision equipment, it finds applications in semiconductor manufacturing tools, optical alignment systems, and medical device machinery, where its stability supports micron-level accuracy. Overall, the THK NR X NR SLRX SERIES delivers a combination of strength, longevity, and precision, making it a trusted solution for industries reliant on robust linear motion components to drive efficiency and innovation.

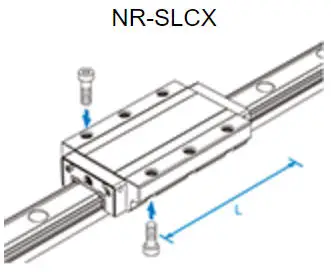

THK's LM Guide NR-X/NR-SLCX Series represents the pinnacle of full-ball type linear motion technology, engineered specifically for applications demanding ultra-heavy load capacity and exceptional rigidity in a radial load configuration. This series is characterized by its robust construction, where a full complement of precision balls makes continuous contact with the raceways, maximizing the load-bearing area and distributing forces evenly across the guide mechanism. The design incorporates large-diameter balls and optimized groove profiles in both the rail and block, creating a system capable of withstanding significant moment loads and impact forces that would compromise conventional linear guides. A key differentiator is the inclusion of THK's proprietary SLC (Seal with Lubrication Cartridge) system in the NR-SLCX variant, which integrates multi-layer contact seals with a built-in grease reservoir to provide long-term, maintenance-free lubrication and superior protection against contaminants like metal chips, dust, and moisture.

The performance advantages of the NR-X/NR-SLCX Series are substantial and directly address the challenges of heavy-duty automation. Its most prominent feature is an ultra-high load rating, which can be several times greater than standard ball-type linear guides of comparable size, allowing for the downsizing of machinery frames or the handling of heavier workpieces without increasing the system's footprint. The full-ball design and rigid structure contribute to remarkably high stiffness, minimizing deflection under load and ensuring positional accuracy and repeatability even during high-force operations. This stability is critical for maintaining precision over long strokes. Furthermore, the smooth, low-friction motion achieved through precision grinding and optimal ball recirculation results in consistent movement, reduced stick-slip, and lower required driving force, contributing to energy efficiency and prolonged service life of both the guide and the associated drive components.

In industrial machinery, the NR-X/NR-SLCX Series is indispensable for heavy-duty machine tools, such as large milling machines, boring machines, and gear cutting equipment, where it provides the stable and precise movement for massive cutting heads and tables. It is also found in injection molding machines, where it supports the immense clamping forces, and in heavy-material handling systems like automated stacker cranes and transfer lines in steel processing plants. Within the automotive manufacturing sector, these guides are deployed in large stamping presses, robotic welding cells handling car bodies, and precision assembly lines for engines and transmissions, where their robustness ensures uninterrupted operation under extreme loads. For precision equipment, the series is utilized in large-scale semiconductor manufacturing apparatus, such as steppers and wafer handlers, and in precision measuring instruments that require unwavering stability for large work envelopes, proving that heavy load capacity and high precision are not mutually exclusive.

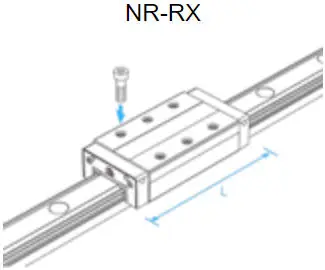

THK's LM Guide NR X and NR RX SERIES represent the pinnacle of linear motion technology for ultra-heavy load applications, engineered specifically to handle extreme radial forces with uncompromising precision and durability. These full ball type LM Guides feature a unique structural design where the load-bearing balls are arranged to maximize contact area and distribute stress evenly across the raceway. This configuration ensures exceptional load capacity while maintaining smooth, low-friction movement even under the most demanding conditions. The series incorporates THK's advanced manufacturing techniques, including precision grinding of raceways and optimized ball circulation paths, to deliver consistent performance and extended service life.

Key technical features of the NR X and NR RX SERIES include their reinforced housing construction, which provides superior rigidity and resistance to deformation under heavy loads. The full ball complement design increases the number of load-carrying balls compared to standard LM Guides, significantly enhancing both static and dynamic load ratings. These guides incorporate THK's proprietary Caged Ball technology, which prevents ball-to-ball contact and reduces heat generation, thereby maintaining accuracy over prolonged operation. The series offers various preload options to match specific application requirements, from zero clearance for high precision to heavy preload for maximum rigidity. Sealing systems are engineered to provide comprehensive protection against contaminants, featuring multiple lip seals and optional scrapers for harsh environments where dust, chips, or moisture are present.

Performance advantages make these LM Guides ideal for challenging industrial applications. Their ultra-high load capacity allows for more compact machine designs while handling forces that would typically require larger or multiple standard guides. The optimized ball circulation system ensures smooth motion characteristics with minimal variation in friction, contributing to improved positioning accuracy and reduced servo motor requirements. These guides demonstrate exceptional resistance to shock loads and vibration, maintaining stability during rapid acceleration and deceleration cycles. The low maintenance design, with optional lubrication units available, reduces downtime and operational costs while ensuring consistent performance throughout the equipment lifecycle.

Typical applications span multiple industries where reliability under extreme loads is paramount. In industrial machinery, these guides are deployed in heavy-duty machining centers for supporting massive workpieces, large-scale transfer systems handling substantial weights, and precision grinding machines requiring stability under cutting forces. Automotive manufacturing utilizes them in robotic welding systems for vehicle frames, heavy press automation equipment, and assembly line transfer mechanisms moving engine blocks and transmission components. Precision equipment applications include semiconductor manufacturing systems handling wafer processing equipment, large coordinate measuring machines requiring stability during measurement cycles, and medical device manufacturing equipment where precision must be maintained despite substantial operating forces. The NR X and NR RX SERIES' combination of ultra-heavy load capacity, precision engineering, and robust construction makes them the preferred solution for applications where failure is not an option and performance must exceed conventional limits.

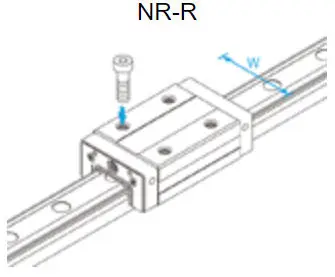

The THK LM Guide NR X/NR R Series represents a significant advancement in linear motion technology, specifically engineered to manage ultra-heavy loads with exceptional stability and precision. As a full-ball type, radial-style LM Guide, this series is distinguished by its robust construction and optimized load distribution, making it an indispensable component in applications demanding high rigidity and unwavering performance under extreme conditions.

At the core of the NR X/NR R Series' technical prowess is its full-ball contact design. Unlike standard designs, this configuration ensures that the entire complement of balls within the raceway maintains contact with the guide rails. This maximizes the load-bearing surface area, dramatically enhancing both static and dynamic load capacities. The radial-type structure is specifically calibrated to support loads acting perpendicularly to the axis of motion, providing superior resistance to moment forces and preventing deflection or misalignment. The guides incorporate THK's proprietary precision grinding technology, resulting in raceways of exceptional geometric accuracy and surface finish. This minimizes friction, reduces operational noise, and ensures consistently smooth, low-vibration travel over the entire stroke length. For protection in harsh environments, advanced sealing systems are integrated to effectively exclude contaminants like dust, chips, and moisture, while simultaneously retaining lubrication to guarantee a long operational life with minimal maintenance.

The performance advantages of this series are substantial and directly address the challenges of heavy-duty automation. Its most prominent benefit is an unparalleled capacity for ultra-heavy loads, allowing machinery designers to handle larger workpieces, apply greater force, or utilize more powerful actuators without compromising system integrity. The high rigidity inherent in the design translates to minimal elastic deformation under load, which is critical for maintaining precise positioning accuracy and repeatability. This stability suppresses vibration, leading to smoother operation, improved surface finishes in machining applications, and reduced wear on the guide and associated components. The efficient rolling motion of the full-ball complement contributes to a low and consistent coefficient of friction, which enhances energy efficiency and allows for more precise control at varying speeds.

These characteristics make the THK NR X/NR R Series ideally suited for a wide range of demanding industrial applications. In heavy industrial machinery, it is the component of choice for the linear axes of large-scale machining centers, gantry-type milling machines, and heavy-duty press feeds, where it provides the foundation for powerful and accurate material removal. Within the automotive manufacturing sector, these guides are deployed in massive robotic welding arms, heavy-part transfer systems, and precision stamping presses, enduring continuous, high-impact cycles. For precision equipment, the series finds its place in large-format coordinate measuring machines (CMMs), semiconductor fabrication equipment handling heavy wafer cassettes, and the precise positioning stages used in aerospace component assembly, where its stability ensures micron-level accuracy even under substantial weight.

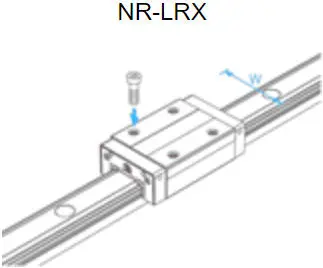

THK's LM Guide NR X/NR LRX SERIES represents a significant advancement in linear motion technology, specifically engineered to manage ultra-heavy loads with exceptional precision and reliability. This full ball type, radial configuration guide is designed for the most demanding industrial applications where high load capacity, rigidity, and long-term accuracy are non-negotiable. The series incorporates a unique ball circulation system that ensures smooth, uninterrupted motion even under extreme conditions, minimizing friction and wear while maximizing operational lifespan.

Key technical features of the NR X/NR LRX SERIES include its robust construction with a reinforced housing and specially hardened steel tracks, providing superior resistance to deformation under heavy radial loads. The full ball design maximizes the contact area between the balls and raceways, distributing load evenly and reducing stress concentrations. This results in a significantly higher load rating compared to standard linear guides. Pre-loaded ball assemblies eliminate internal clearance, enhancing system rigidity and positioning accuracy. Additionally, the inclusion of advanced seals and wipers protects against contaminants such as dust, chips, and moisture, ensuring consistent performance in harsh environments. Optional configurations include custom lengths, lubrication units, and corrosion-resistant treatments to suit specific operational needs.

Performance advantages are immediately evident in its ability to sustain ultra-heavy loads without sacrificing smoothness or precision. The low friction coefficient translates to reduced power consumption and lower heat generation, contributing to energy efficiency and extended component life. High rigidity minimizes deflection during operation, maintaining alignment and repeatability even under dynamic or moment loads. The design also dampens vibrations, leading to quieter operation and reduced transmission of shocks to connected machinery. Maintenance requirements are minimal due to the efficient lubrication retention and contamination exclusion features, reducing downtime and total cost of ownership.

Typical applications span industries where heavy-duty precision is critical. In industrial machinery, the NR X/NR LRX SERIES is integral to large-scale CNC machining centers, heavy-duty milling machines, and precision grinding equipment, where it supports massive workpieces and cutting forces. Within automotive manufacturing, it is employed in robotic welding systems, automated assembly lines, and stamping presses, handling high loads with repeatable accuracy. In precision equipment, it finds use in semiconductor fabrication tools, large-scale coordinate measuring machines (CMMs), and optical positioning systems, where stability and minimal deviation are essential. Its versatility also extends to aerospace component handling, metal forming presses, and heavy material handling systems, demonstrating its capability to enhance productivity and reliability across diverse sectors.

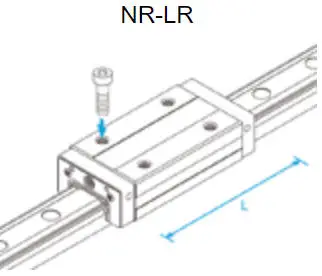

The THK LM Guide NR X NR LR SERIES represents a full ball type linear motion guide specifically engineered for ultra-heavy load applications, utilizing a radial-type design to deliver exceptional load capacity, rigidity, and precision in the most demanding industrial environments. This series incorporates a full ball circulation system where balls roll along four axial arcs, ensuring smooth, consistent motion and optimal load distribution across all contact surfaces. The radial-type configuration directs loads perpendicular to the mounting surface, making it ideal for applications subjected to significant vertical or radial forces. Constructed from high-grade steel with advanced heat treatment processes, the LM Guide offers superior durability, wear resistance, and long-term operational reliability, even under harsh conditions involving shock, vibration, or contamination.

Key technical features include an enhanced ball groove geometry that maximizes contact area between the balls and raceways, significantly increasing load ratings while minimizing stress concentration. The NR X NR LR SERIES is designed with a high rigidity structure, incorporating larger ball diameters and optimized recirculation paths to handle moment loads and complex force vectors without compromising performance. Pre-load adjustments are precisely calibrated to eliminate internal clearance, ensuring zero backlash and high positional accuracy. Sealing systems integrate multiple layers of protective seals and scrapers to prevent ingress of dust, chips, and fluids, extending service life in contaminated environments. Lubrication options are designed for easy maintenance, with grease nipples and lubrication units facilitating consistent lubricant supply to critical contact points.

Performance advantages of this series are evident in its ability to sustain ultra-heavy loads without deformation or loss of precision, making it a reliable choice for high-stress applications. The full ball circulation minimizes friction, resulting in smooth, low-noise operation and reduced energy consumption. High-speed capabilities are maintained due to efficient heat dissipation and stable rolling motion, while the rigidity of the system ensures minimal deflection under load, enhancing machining or positioning accuracy. These attributes contribute to extended maintenance intervals and reduced total cost of ownership, as the components are built to withstand continuous, heavy-duty cycles with minimal wear.

Typical applications span across industrial machinery, automotive systems, and precision equipment where robust linear guidance is critical. In industrial settings, the NR X NR LR SERIES is employed in heavy-duty machine tools, such as milling machines, boring mills, and grinding equipment, where it supports massive workpieces and cutting forces with high precision. Within the automotive industry, it is utilized in welding robots, assembly line transfer systems, and stamping presses that require reliable motion under extreme loads and repetitive cycles. Precision equipment applications include large-scale semiconductor manufacturing apparatus, optical alignment systems, and inspection machines that demand unwavering accuracy and stability. By integrating this LM Guide, engineers can achieve enhanced performance, reliability, and efficiency in applications that push the boundaries of linear motion technology.

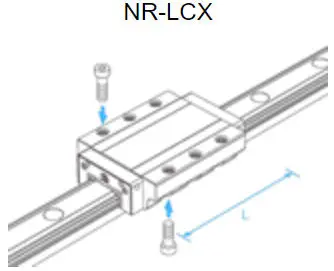

THK's LM Guide NR X NR LCX SERIES represents a significant advancement in linear motion technology, specifically engineered to handle ultra-heavy loads with exceptional precision and reliability. This full ball type, radial configuration guide is designed for the most demanding industrial applications where high load capacity, rigidity, and long-term accuracy are paramount. The series incorporates a unique raceway design that maximizes the number of recirculating balls, distributing load evenly across the guide system to withstand substantial radial forces without compromising smooth motion.

Key technical features of the NR X NR LCX SERIES include its full ball contact structure, which ensures uniform stress distribution and minimizes deformation under heavy loads. The radial-type configuration provides superior resistance to moment loads, enhancing stability in applications subject to tilting or overturning forces. Components are manufactured from high-grade steel, subjected to THK's proprietary heat treatment processes to achieve optimal hardness and wear resistance. The integrated sealing systems effectively exclude contaminants like dust, chips, and moisture while retaining lubrication, significantly extending service intervals and operational lifespan. Pre-loaded ball circuits eliminate backlash, maintaining precise positioning even under varying load conditions.

Performance advantages are substantial across multiple dimensions. The design delivers exceptionally high static and dynamic load ratings, capable of supporting machinery components weighing several tons while maintaining smooth linear movement. Rigidity is significantly enhanced compared to standard linear guides, reducing deflection under load to maintain accuracy in precision applications. The optimized recirculation system minimizes friction, resulting in lower operating temperatures and reduced energy consumption. With noise levels controlled through precision manufacturing, these guides operate quietly even at high speeds. Maintenance requirements are minimal due to the effective sealing and high-quality lubrication, ensuring consistent performance over extended periods without frequent servicing.

Typical applications span multiple industries where robust linear motion solutions are critical. In industrial machinery, the NR X NR LCX SERIES is implemented in heavy-duty machining centers, large-scale transfer lines, and press feeding equipment where high load capacity and precision are essential. The automotive industry utilizes these guides in robotic welding systems, assembly line transporters, and component testing machinery that require reliable performance under continuous heavy loads. Precision equipment applications include large coordinate measuring machines, semiconductor manufacturing systems, and optical positioning devices where vibration damping and positional accuracy are crucial. The series' durability makes it suitable for harsh environments including foundries, steel mills, and mining equipment where contamination resistance and structural integrity are vital for operational safety and efficiency.

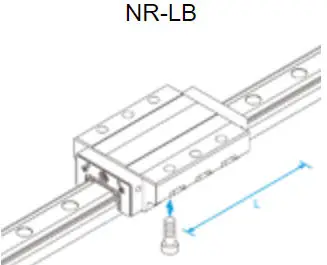

The THK LM Guide NR X NR LB SERIES represents a specialized ultra-heavy load linear motion solution engineered for applications demanding exceptional radial load capacity and rigidity. As a full ball type LM Guide, this series utilizes a comprehensive ball recirculation system where balls make contact along the entire raceway groove, maximizing load distribution and moment resistance. The radial-type design focuses on supporting loads perpendicular to the guide axis, making it particularly suitable for vertical or heavily offset load conditions where traditional guides might experience premature failure or excessive deformation.

Key technical features include an optimized ball groove profile that increases contact area between the balls and raceway, significantly enhancing load ratings. The NR X NR LB SERIES incorporates a larger ball diameter and increased ball count within a compact cross-section, achieved through precision manufacturing of the rail and block components. A reinforced seal system with multi-layer contact seals and metal scrapers provides robust protection against contaminants like metal chips, coolant, and dust in harsh operating environments. The series is available with preloaded options to eliminate internal clearance, ensuring high positional accuracy and minimal deflection under load. Standard lubrication units or optional centralized lubrication ports facilitate maintenance, extending service life even in high-duty cycles.

Performance advantages are substantial in demanding scenarios. The ultra-high radial load capacity allows for downsizing of linear motion systems, as a single NR X NR LB unit can often replace multiple standard guides, saving space and reducing overall mechanical complexity. Rigidity is markedly improved, with high moment stiffness resisting pitch, yaw, and roll forces, which maintains precision alignment of mounted components. Smooth motion with consistent friction characteristics is achieved through the efficient ball recirculation, contributing to precise velocity control and reduced servo system hunting. These guides exhibit low noise and vibration levels despite heavy loading, promoting a better working environment and protecting sensitive equipment. Durability is exceptional, with calculated travel life ratings far exceeding conventional guides under equivalent loads, reducing machine downtime and total cost of ownership.

Typical applications leverage these strengths across multiple industries. In industrial machinery, the NR X NR LB SERIES is ideal for heavy-duty machining centers performing aggressive milling or boring operations, where the spindle carrier undergoes significant radial cutting forces. They are employed in large-scale injection molding machines to guide the moving platen, which experiences high clamping tonnage. Within automotive manufacturing, these guides are found in heavy robotic welding arms and large transfer lines handling engine blocks or vehicle frames. For precision equipment, they provide stable motion in large coordinate measuring machines (CMM) and semiconductor manufacturing platforms where heavy optics or process heads must be positioned without sag or deflection. The series is also specified in press feeds, stamping equipment, and large assembly automation where reliability under extreme radial loads is non-negotiable.

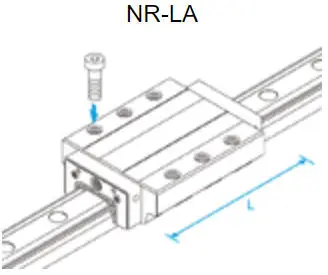

The THK LM Guide NR X NR LA SERIES represents a significant advancement in linear motion technology, specifically engineered to handle ultra-heavy loads with exceptional precision and reliability. As a full ball type radial LM guide, this series incorporates a unique design where the ball grooves are arranged in a radial configuration, allowing for the accommodation of substantial loads from all directions—radial, reverse radial, and lateral. This design is particularly beneficial in applications where high rigidity and load capacity are paramount, ensuring stable and accurate motion even under the most demanding conditions.

Key technical features of the NR X NR LA SERIES include its full ball contact structure, which maximizes the number of load-bearing balls in the raceway. This configuration enhances load distribution and minimizes elastic deformation, leading to improved stiffness and longevity. The guide rails and blocks are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment processes to achieve superior hardness and wear resistance. Additionally, the series boasts an optimized sealing system with multiple seals and scrapers that effectively prevent contaminants such as dust, chips, and moisture from entering the ball circuits, thereby maintaining smooth operation and extending service life in harsh environments. Pre-loaded ball assemblies are standard, eliminating backlash and ensuring high positional accuracy, which is critical for precision applications.

Performance advantages of this series are evident in its ability to support ultra-heavy loads while maintaining low friction and high-speed capabilities. The radial type design allows for a compact form factor without compromising on load capacity, making it an ideal solution for space-constrained installations. Its high rigidity reduces vibration and deflection, contributing to enhanced machining accuracy and surface finish in industrial settings. Moreover, the low noise and maintenance requirements of the NR X NR LA SERIES translate to reduced downtime and operational costs, boosting overall productivity.

Typical applications span a wide range of industries, including heavy-duty industrial machinery such as CNC machining centers, where it facilitates precise table movements under significant cutting forces. In automotive systems, it is employed in robotic welding arms, assembly lines, and press machines that demand robust load handling and repeatability. For precision equipment, this series finds use in semiconductor manufacturing devices, optical positioning stages, and medical imaging systems, where its accuracy and reliability ensure consistent performance. By integrating the THK LM Guide NR X NR LA SERIES, engineers can achieve superior motion control, durability, and efficiency in their most challenging applications.

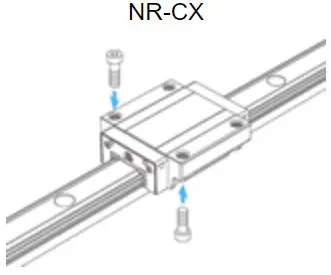

THK's LM Guide NR X and NR CX SERIES represent a significant advancement in linear motion technology, specifically engineered to handle ultra-heavy loads with exceptional precision and reliability. These full ball type, radial configuration guides are designed for applications where high load capacity, rigidity, and durability are paramount. The series incorporates a unique raceway geometry that maximizes ball contact, distributing loads evenly across the rolling elements to withstand substantial radial forces while maintaining smooth, low-friction motion. Constructed from high-grade steel and subjected to THK's proprietary heat treatment processes, these components exhibit superior wear resistance and long-term operational stability, even in harsh industrial environments.

Key technical features of the NR X and NR CX SERIES include their optimized ball circulation system, which ensures consistent lubrication and minimizes heat generation during high-speed or high-load operations. The guides are pre-loaded to eliminate backlash, providing high positional accuracy and repeatability essential for precision applications. Their sealed design incorporates advanced sealing technologies to prevent contamination from dust, chips, and other particulates, thereby extending service life and reducing maintenance requirements. Additionally, the series offers various accuracy grades and preload levels, allowing for customization to meet specific performance criteria.

Performance advantages are evident in their ability to support ultra-heavy loads without compromising on smoothness or precision. The radial type design ensures high rigidity and moment load capacity, making them ideal for applications subjected to significant side forces or overturning moments. Low friction coefficients contribute to energy efficiency, reducing operational costs and heat buildup. The guides' robust construction and precision manufacturing result in quiet operation, minimal vibration, and enhanced system longevity, even under continuous heavy-duty use.

Typical applications span multiple industries, leveraging the series' strengths in demanding environments. In industrial machinery, they are commonly used in heavy-duty CNC machining centers, large-scale transfer lines, and press feeding equipment where high load capacity and precision are critical. Within automotive systems, these guides find application in robotic welding arms, assembly line conveyors, and testing equipment that require reliable performance under repetitive heavy loads. For precision equipment, the NR X and NR CX SERIES are employed in semiconductor manufacturing apparatus, large coordinate measuring machines, and optical alignment systems where accuracy and stability under load are non-negotiable. Their versatility and robustness make them a preferred choice for engineers seeking to enhance the performance and reliability of machinery operating under extreme conditions.

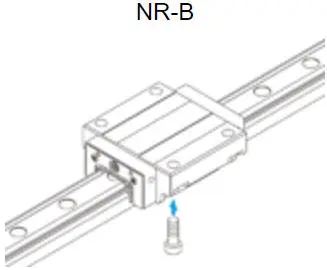

The THK LM Guide NR X/NR B SERIES represents a significant advancement in linear motion technology, specifically engineered as a full ball type, ultra-heavy load radial guide system. Designed to withstand extreme operational demands, this series incorporates a robust structure where the rolling elements—balls—are arranged in a full complement configuration without retainers, maximizing the number of load-bearing components. This design directly translates to superior load capacity, making it ideal for applications requiring exceptional rigidity and durability under high-stress conditions. The radial-type configuration ensures that loads are distributed evenly across the guide, enhancing stability and precision even when subjected to substantial forces in multiple directions.

Key technical features of the NR X/NR B SERIES include its ability to handle ultra-heavy loads, thanks to the full ball contact design that increases the contact area between the balls and raceways. This results in higher static and dynamic load ratings compared to standard LM guides. The series also incorporates THK's proprietary precision machining, ensuring smooth, low-friction motion with minimal deflection. Additionally, it features enhanced sealing mechanisms to protect against contaminants like dust, chips, and moisture, which is critical in harsh industrial environments. The guide rails and blocks are manufactured from high-grade steel, heat-treated for wear resistance and long service life, while optional coatings can further improve corrosion resistance.

Performance advantages of this series are evident in its reliability and efficiency. It offers reduced vibration and noise levels, contributing to smoother operation and extended component lifespan. The high rigidity minimizes elastic deformation under load, maintaining accuracy in positioning tasks. Moreover, its low maintenance requirements and energy-efficient design help lower total cost of ownership. These attributes make it suitable for high-speed applications where precision and stability are non-negotiable.

Typical applications span various demanding sectors. In industrial machinery, the NR X/NR B SERIES is commonly used in heavy-duty CNC machining centers, press feeds, and injection molding machines, where it supports precise linear movement under substantial weights. In automotive systems, it finds use in robotic welding arms, assembly line conveyors, and testing equipment that require robust performance and repeatability. For precision equipment, it is employed in semiconductor manufacturing devices, optical alignment systems, and medical diagnostics machinery, ensuring accurate, reliable motion control in critical processes. Overall, this series delivers a dependable solution for industries pushing the boundaries of load capacity and precision.

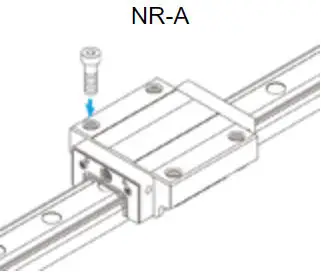

The THK LM Guide NR X/NR A SERIES represents a pinnacle in linear motion technology, engineered specifically for ultra-heavy load applications where radial load capacity and unwavering precision are paramount. As a full ball type LM guide, this series incorporates a unique design where recirculating balls make full contact along the raceways of both the rail and block, maximizing load distribution and rigidity. The radial-type configuration ensures optimal performance under substantial forces perpendicular to the direction of motion, making it an indispensable component in the most demanding industrial environments.

Technically, the NR X/NR A SERIES is distinguished by its high load capacity, which is achieved through a combination of a large ball diameter, an increased number of load-bearing balls, and a optimized contact angle. The guide features a rigid, one-piece cast iron or steel block that minimizes deformation under load. A high-performance seal system is integrated to effectively exclude contaminants like dust, chips, and moisture, while retaining grease, thereby ensuring long-term operational reliability and minimal maintenance. The precision-ground raceways provide smooth, low-friction motion with high positional accuracy and repeatability. Furthermore, the design often includes lubrication units for easy re-greasing, extending service intervals even in harsh conditions.

The performance advantages of this series are substantial. Its exceptional rigidity and high static and dynamic load ratings directly translate to improved machining accuracy and surface finishes in equipment, as it resists deflection under cutting forces or heavy workpieces. The stability dampens vibrations, leading to quieter operation and prolonged life for both the guide and the machinery itself. Its high durability and wear resistance ensure consistent performance over an extended service life, reducing downtime and total cost of ownership. The efficient sealing guarantees reliable operation in environments plagued by particulate contamination or occasional fluid exposure.

Typical applications for the THK NR X/NR A SERIES are found wherever massive loads must be moved with precision. In industrial machinery, it is the backbone of large-scale machining centers, heavy-duty milling machines, boring machines, and injection molding machines, where it supports the weight of the table, workpiece, and the intense forces generated during metal cutting or plastic injection. Within the automotive manufacturing sector, these guides are critical for massive robotic welding arms, heavy-part transfer lines, and large stamping press automation systems. In the realm of precision equipment, they facilitate accurate motion in large-scale coordinate measuring machines (CMMs), semiconductor fabrication equipment handling heavy wafer stages, and advanced aerospace assembly jigs. Ultimately, the NR X/NR A SERIES provides the robust, reliable foundation necessary for the most challenging applications that define modern heavy industry and precision manufacturing.