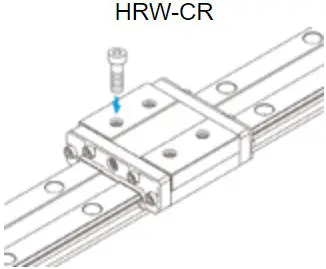

The THK LM Guide HRW CR SERIES represents a high-capacity linear motion solution engineered for applications demanding exceptional rigidity, heavy load support, and long-term precision under severe operating conditions. This "Wide Rail" full ball type LM Guide is characterized by its significantly wider rail and block structure compared to standard models. This fundamental design enhancement provides a larger load-bearing surface and a more generous ball circulation pathway, directly translating to superior moment load capacity and enhanced stability. The HRW CR SERIES is meticulously designed to resist deflection and maintain accuracy even when subjected to substantial overturning, lateral, and pitching moments, making it an indispensable component for heavy-duty industrial machinery.

Key technical features of the HRW CR SERIES begin with its full-ball contact design. Unlike designs that use fewer load-carrying balls, the full-ball configuration ensures that a maximum number of balls are in contact with the raceways at all times. This distributes loads more evenly, drastically reducing contact stress on individual balls and the raceway, which is a primary factor in its extended service life and high static load rating. The series incorporates THK's advanced precision grinding technology for both the rail and the block, guaranteeing high running parallelism and smooth, low-friction motion with minimal variation. Sealing is another critical feature; the HRW CR SERIES is equipped with highly effective multi-layer seals and scrapers that form a comprehensive defense against contaminants such as metal chips, abrasive dust, and moisture. This robust sealing system is vital for preserving lubricant integrity and preventing premature wear in harsh environments.

The performance advantages derived from this design are substantial. The most prominent benefit is its unparalleled rigidity and load capacity. The wide rail design provides immense resistance to moment forces, effectively preventing block tilt and ensuring consistent, repeatable positioning. This results in improved machining accuracy, reduced vibration, and quieter operation in high-load scenarios. Furthermore, the high rigidity allows for higher feed rates and accelerations without sacrificing precision, contributing to shorter cycle times and increased productivity. The combination of the full-ball design and superior seals grants the HRW CR SERIES exceptional durability and reliability, leading to reduced maintenance intervals and lower total cost of ownership over the system's lifespan.

Typical applications for the THK HRW CR SERIES are found wherever massive loads and critical precision converge. In industrial machinery, it is the guiding element of choice for heavy-duty machining centers, large-scale milling machines, boring machines, and high-precision grinding equipment. Its ability to withstand heavy cutting forces and moments makes it ideal for the main axes of these machines. Within the automotive manufacturing sector, the HRW CR SERIES is deployed in large welding robots, heavy-duty transfer lines, and massive press automation systems where its robustness ensures continuous, reliable operation. In the realm of precision equipment, it finds use in large-scale coordinate measuring machines (CMMs), semiconductor manufacturing equipment for handling heavy wafer cassettes, and various high-precision assembly systems that require unwavering stability under significant load.

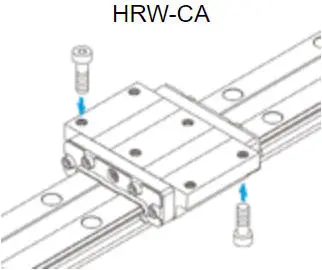

The THK LM Guide HRW CA SERIES represents a robust linear motion solution engineered for applications demanding exceptional rigidity, high load capacity, and unwavering precision under the most severe operational conditions. As a wide rail, full ball type LM Guide, this series is fundamentally designed to manage substantial loads and moments with minimal deformation, ensuring long-term accuracy and reliability in heavy-duty industrial environments. Its construction features a generously proportioned rail and block assembly, which provides a large contact area for the recirculating ball circuits, directly contributing to its superior load-bearing characteristics and enhanced stability.

Key technical features define the performance envelope of the HRW CA SERIES. The "full ball type" design signifies that the entire circumference of the ball grooves is utilized for load carrying, maximizing the number of load-bearing balls compared to standard designs. This configuration dramatically increases the radial load capacity, moment load capacity (including pitch, yaw, and roll moments), and rigidity. The wide rail geometry further augments this by providing a broader base, which resists overturning forces and distributes stress more effectively. Components are manufactured from high-carbon chromium bearing steel, subjected to rigorous heat treatment processes to achieve a surface hardness that guarantees exceptional wear resistance and an extended service life. The integrated sealing systems are comprehensive, employing multi-lip seals and scrapers to effectively exclude contaminants like metal chips, dust, and moisture, while simultaneously retaining the high-performance grease, making the units highly suitable for dirty or wash-down environments.

The performance advantages are immediately apparent in operational settings. The immense static and dynamic load ratings allow for the design of more compact machinery, as fewer guides or smaller units can be specified to handle a given load, saving space and weight. The high rigidity ensures minimal deflection under load, which is critical for maintaining positional accuracy and repeatability in precision machining and assembly processes. This stability also contributes to dampening vibrations, leading to smoother motion, reduced noise levels, and improved surface finish in machining applications. The optimized sealing and efficient grease lubrication system significantly extend the maintenance intervals, reducing total cost of ownership and machine downtime.

Typical applications for the THK HRW CA SERIES are found wherever heavy loads, high moments, and precision are non-negotiable. In industrial machinery, it is the guiding element of choice for heavy-duty machining centers, large-scale transfer lines, injection molding machines, and precision grinding equipment. The automotive industry utilizes these guides in robotic welding and assembly systems, heavy-duty material handling gantries, and stamping press feeders. Within precision equipment, the HRW CA SERIES provides the stable foundation for large-format coordinate measuring machines (CMMs), semiconductor manufacturing equipment like steppers, and advanced optical positioning systems, where its ability to maintain accuracy under significant load is paramount.