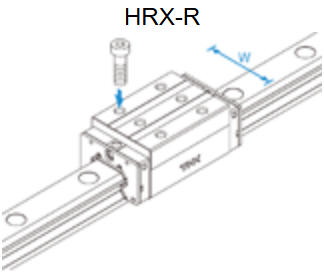

The THK LM Guide HRX/R Series represents a significant advancement in linear motion technology, featuring a full roller, 4-way equal load design that delivers unparalleled rigidity, precision, and longevity in demanding applications. This model utilizes cylindrical rollers arranged in a unique configuration where loads are uniformly distributed across all four cardinal directions—radial, reverse radial, and lateral forces are all supported with equal capacity. This 4-way equal load structure ensures exceptional stability and resistance to moment loads, making the HRX/R Series ideal for environments subject to complex force interactions and heavy operational stresses.

Key technical features of the HRX/R Series include its full roller contact system, which maximizes the contact area between the rollers and raceways. This design minimizes elastic deformation under load, significantly enhancing rigidity and positional accuracy. The rollers are precision-ground and manufactured to exacting tolerances, ensuring smooth, consistent motion with minimal friction. The guide is equipped with a patented retainer system that prevents roller-to-roller contact, reducing wear and extending service life even at high speeds. Additionally, the HRX/R Series incorporates advanced sealing technologies to protect against contaminants such as dust, chips, and moisture, maintaining performance in harsh industrial environments. Pre-loaded options are available to eliminate backlash, providing precise, repeatable motion critical for high-accuracy applications.

Performance advantages of this LM Guide are substantial, offering higher load capacities and stiffness compared to traditional ball-based guides. The full roller design allows for greater load distribution, resulting in a longer rated life and reduced maintenance requirements. Its ability to handle heavy loads and moment forces with minimal deflection ensures consistent precision in positioning tasks. The low friction characteristics contribute to smoother motion, reduced energy consumption, and lower heat generation, enhancing overall system efficiency. These attributes make the HRX/R Series capable of operating at higher speeds and accelerations without sacrificing accuracy or durability.

Typical applications for the THK HRX/R Series span a wide range of industries where reliability and precision are paramount. In industrial machinery, it is commonly used in heavy-duty CNC machining centers, grinding machines, and milling equipment that require robust support for high-load cutting operations. Within automotive manufacturing systems, the HRX/R Series is employed in robotic welding arms, precision assembly lines, and transfer systems that demand rigorous performance under continuous operation. In the realm of precision equipment, these guides are integral to semiconductor manufacturing apparatus, optical positioning stages, and precision measuring instruments where nanometer-level accuracy and stability are essential. The HRX/R Series’ resilience and precision also make it suitable for applications in aerospace component fabrication and large-scale material handling systems, ensuring reliable performance in the most challenging operational conditions.

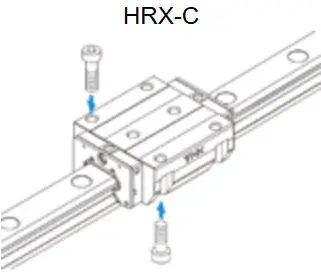

The THK LM Guide HRX C SERIES represents a full roller type linear motion system engineered for applications demanding exceptional rigidity, precision, and longevity under heavy loads and challenging conditions. This 4-way equal load roller type LM guide utilizes cylindrical rollers as the rolling elements within its raceway, a design that fundamentally distinguishes it from ball-based systems. The "4-way equal load" characteristic is a core feature, meaning the guide can handle equivalent magnitudes of load from all four primary directions—radial, reverse radial, and lateral—simultaneously. This provides unparalleled stability and prevents moment loads from compromising smooth motion, making the system exceptionally robust.

Key technical features of the HRX C SERIES include its optimized roller contact geometry. The rollers make line contact with the raceways, significantly increasing the contact area compared to the point contact found in ball guides. This results in a dramatically higher load capacity and rigidity. The design incorporates a high-rigidity, high-capacity roller retainer that prevents skewing and ensures smooth, continuous circulation of the rollers, even at high speeds. Furthermore, the series is available with various sealing options, such as metal and rubber seals, to provide superior protection against contaminants like dust, chips, and moisture, thereby ensuring reliable operation and extended service life in harsh environments. Pre-loaded options are also available to eliminate clearance and enhance positional accuracy.

The performance advantages are substantial. The immense load capacity allows for the downsizing of machinery, as a smaller guide can handle loads that would typically require a larger ball-type model. The high rigidity minimizes elastic deformation under load, which is critical for maintaining precision during machining, pressing, or measurement operations. This combination of high load capacity and rigidity also contributes to a longer service life and reduced maintenance requirements. The smooth rolling motion of the rollers translates into lower friction and more consistent motion characteristics, even under pre-load, which is vital for high-precision positioning.

Typical applications for the THK HRX C SERIES are found wherever heavy loads, high rigidity, and precision are non-negotiable. In industrial machinery, it is ideally suited for heavy-duty machining centers, grinding machines, injection molding machines, and press feeds. The automotive industry utilizes these guides in robotic welding arms, heavy-duty transfer lines, and precision assembly systems. Within precision equipment, the HRX C SERIES is deployed in semiconductor manufacturing equipment, precision measuring instruments, and optical positioning stages, where its stability and accuracy are paramount. Its robust construction and sealing make it a reliable choice for these demanding sectors, ensuring consistent performance and durability.